How Coordinate Measuring Machines (CMMs) Improve Part Accuracy for Designers

Few things are more frustrating for industrial and product designers than seeing a design lose accuracy as it moves from CAD to the real world. A part looks perfect on screen, assembles cleanly in early samples, and then drifts out of tolerance once production introduces higher cutting speeds, dedicated fixtures, and repeated setups. Features no longer align as intended, and mating components begin to show fit issues that were never visible during early builds.

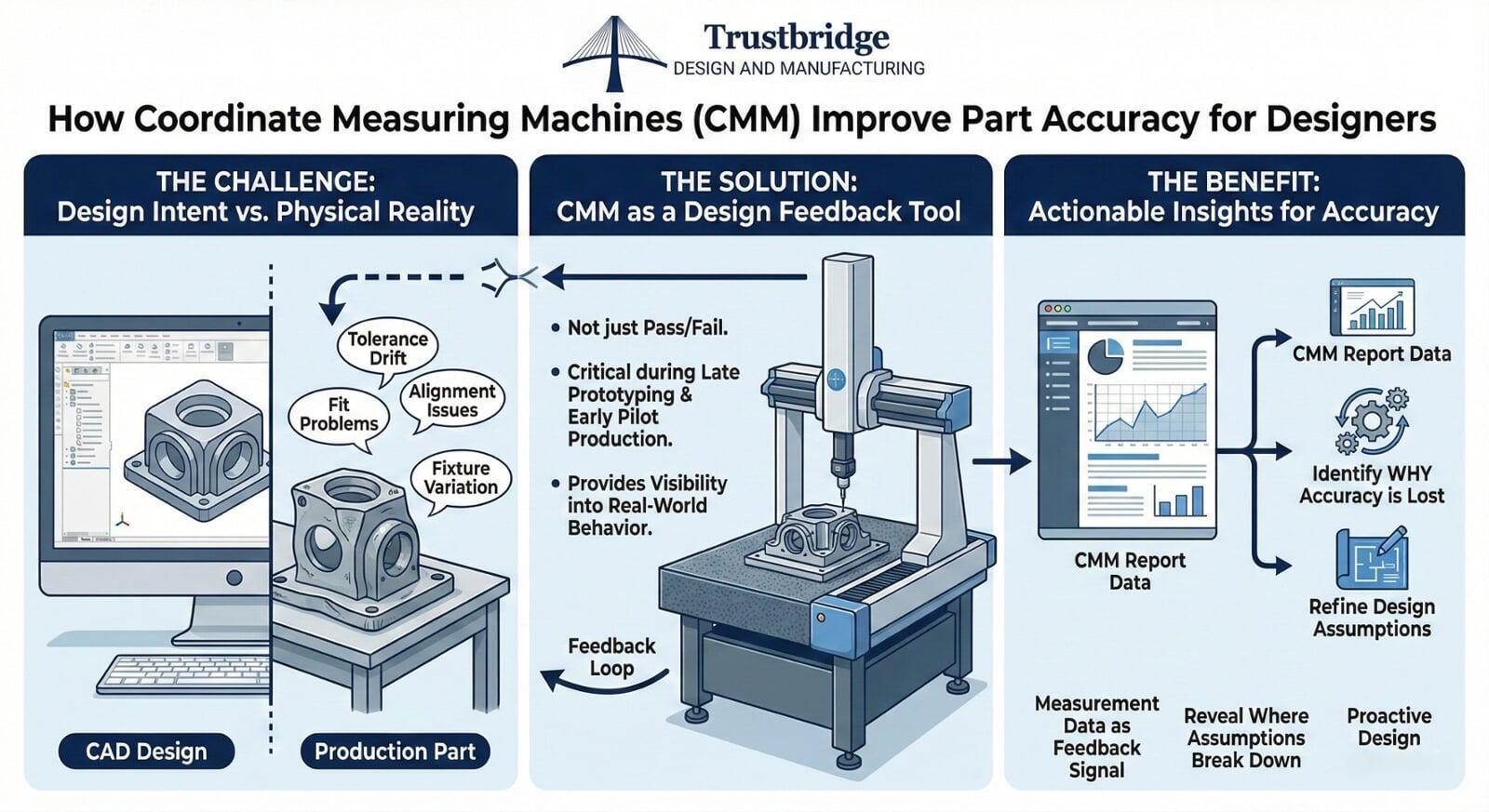

This gap between design intent and physical reality is where the coordinate measuring machine becomes one of the most powerful—but often misunderstood—tools available to designers. While CMMs are typically viewed as pass/fail quality-control equipment, their real value for designers appears much earlier, especially during late prototyping and early pilot production. When designers actively review CMM reports during these stages, measurement data becomes a design feedback signal rather than a compliance checkbox.

For designers, CMMs are not about inspection for inspection’s sake. They are about visibility into how a design behaves once it encounters real machines, real fixtures, and unavoidable variation. Unlike simple pass/fail inspection, CMM feedback reveals why accuracy is lost and where design assumptions begin to break down.

What a Coordinate Measuring Machine Is and Why Designers Should Care

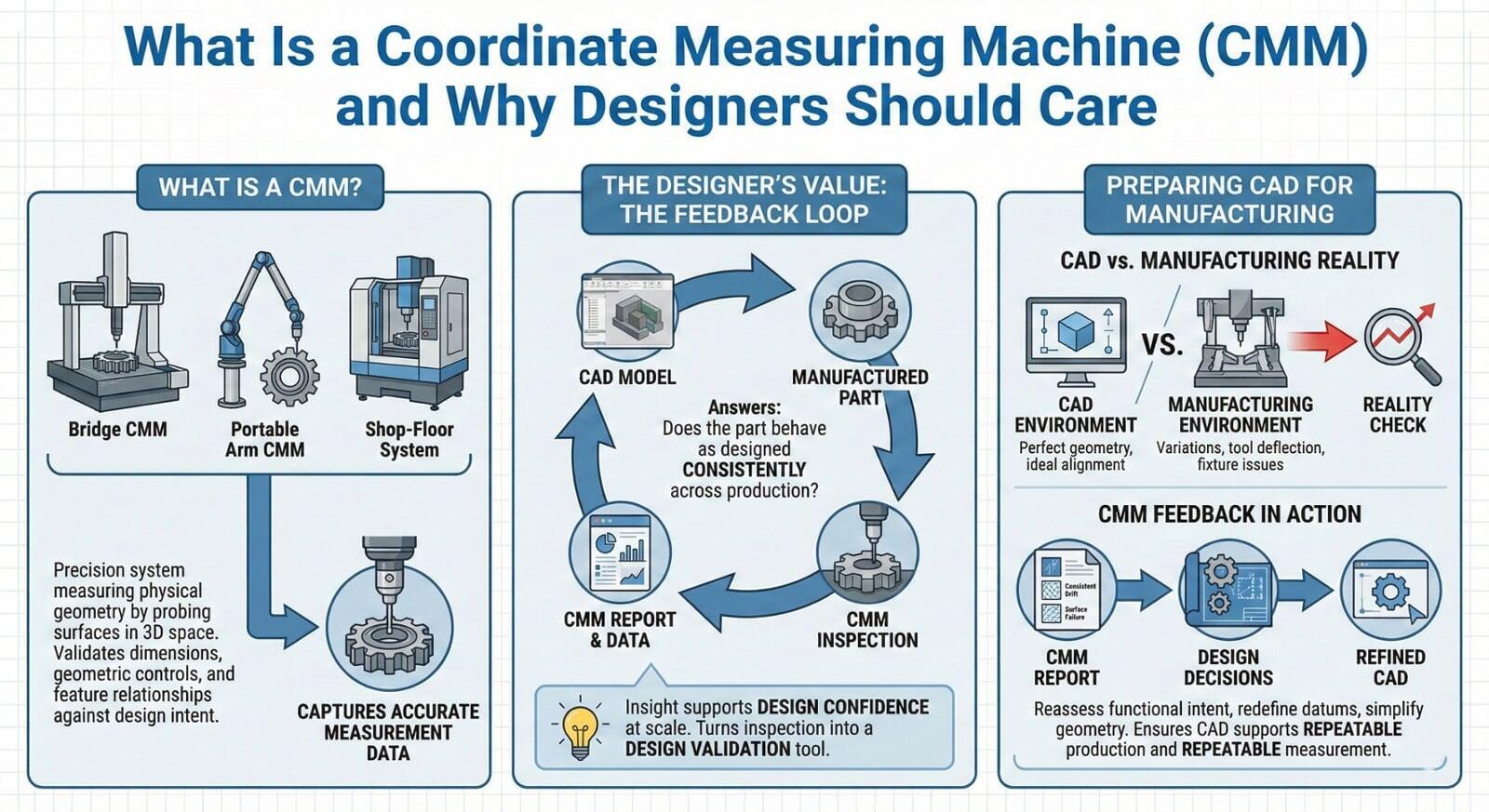

A coordinate measuring machine is a precision system used to measure the physical geometry of a part by probing surfaces and features in three-dimensional space. Common forms include bridge CMMs, portable arm CMMs, and shop-floor systems, all designed to capture accurate measurement data. For designers, these measurements validate whether dimensions, geometric controls, and feature relationships truly reflect design intent once the part exists physically.

From a designer’s perspective, the value of a coordinate measuring machine is not the machine itself, but the feedback loop it creates. CMM results show how CAD geometry, tolerances, and datum schemes translate into manufactured parts across multiple cycles. They answer a critical question CAD alone cannot: does this part behave as designed not just once, but consistently across production volumes?

That insight directly supports design confidence at scale. When designers engage with CMM results early, inspection stops being a downstream policing function and becomes a design validation tool that informs decisions before designs are locked.

Trustbridge Tip: Strengthening Designs Before Measurement Begins

CMM data is most valuable when it confirms good design decisions rather than reacting to failures. Design teams that supplement in-house expertise with manufacturing-aware CAD and CAM insighttend to create parts that machine more predictably and measure more consistently.

When designers understand how toolpaths, setup logic, and machining constraints influence finished geometry, they naturally produce models that align better with real-world production. This alignment reduces dimensional drift, simplifies inspection, and improves confidence as designs move from prototype to production.

Why CAD Alone Cannot Guarantee Part Accuracy

Modern CAD tools are incredibly powerful, and their limitations are well understood rather than flaws. CAD operates in a mathematically perfect environment where geometry is exact, assemblies assume ideal alignment, and tolerances behave predictably. Manufacturing introduces interpretation, variation, and statistical reality.

In production, process variables such as tool deflection and machine repeatability interact with fixture-induced variation and material movement. These effects accumulate statistically across operations and setups. A design that appears dimensionally perfect in CAD can still fail functionally once these influences compound.

This is why designers who rely solely on CAD are often surprised by inspection results. A coordinate measuring machine exposes how design assumptions interact with how parts are actually located, cut, and measured. It reinforces an important truth: measurement strategy is part of the design, not an afterthought.

Using CMM Feedback to Prepare CAD for Manufacturing

One of the most overlooked benefits of CMM data is how directly it improves CAD quality before production ramps up. When designers review inspection reports alongside the CAD model—rather than only reading pass/fail summaries—patterns emerge quickly.

Features that consistently drift, surfaces that fail flatness, or dimensions that show repeatable deviation often point back to design decisions rather than machining errors. These insights allow designers to reassess functional intent, redefine datum references, add relief where necessary, or simplify geometry so CAD reflects manufacturing reality rather than idealized form.

To prepare CAD for manufacturing, designers must consider not just shape, but how that shape will be located, clamped, machined, and inspected. CMM feedback closes this loop by showing whether the CAD model supports repeatable production and repeatable measurement—two conditions that matter equally for scale.

Coordinate Measuring Machines and Design for Manufacturability

Design for manufacturability is often discussed as a set of rules, but CMM data grounds DFM in evidence. It shows where a design is tolerant of variation and where it is sensitive to setup changes or minor process shifts.

Designs that consistently measure within tolerance across multiple parts indicate that geometry, tolerances, and datum structures are aligned with the process. Designs that fail inspection repeatedly—even when suppliers follow the drawing exactly—signal a DFM issue, not a quality failure.

For designers, this distinction matters. A coordinate measuring machine does more than confirm whether a part meets tolerance; it reveals whether the design absorbs variation gracefully. This insight enables design-led cost reduction by eliminating the need for expensive controls such as secondary machining, excessive inspection frequency, or overly tight process constraints.

Tolerances, Datums, and Measurement Intent

Tolerances are promises designers make to manufacturing, and CMMs are how those promises are evaluated. When tolerances are overly tight, poorly tied to function, or unclear in their intent, CMM results become a source of friction. Suppliers struggle to pass inspection not due to lack of capability, but because measurement intent and functional intent are misaligned.

This is where technical drawing importance becomes especially clear. Well-defined datum schemes, clear GD&T controls, and functional tolerances allow CMM programs to align with design intent. For example, defining datums based on functional interfaces rather than cosmetic surfaces improves inspectability and reduces interpretation differences between suppliers and inspectors.

Trustbridge Tip: Designing with Machining Reality in Mind

Design accuracy often breaks down not in CAD, but at the point where ideal geometry meets cutting forces, fixturing constraints, and tool behavior. Designers who factor in how machining strategies affect surface stability and dimensional driftearly in the design phase tend to see fewer surprises when parts reach inspection.

Subtle choices—such as edge conditions, wall orientation, and how features are approached during cutting—can influence how consistently a part measures later on. When these considerations are addressed upfront, CMM results are more likely to reflect design intent rather than expose avoidable variation.

CMMs Across the Prototype to Production Transition

The transition from prototype to production is where many accuracy issues first surface. Prototypes are often built slowly, manually adjusted, and accepted based on limited samples. Production introduces repetition, faster cycle times, and statistical expectations.

A part that passes inspection once is not the same as a part that passes inspection every time. Coordinate measuring machines provide trend data that reveals repeatability, not just isolated success. For designers, this insight enables early containment of risk before high volumes magnify small inaccuracies into widespread fit issues or assembly delays.

Improving Industrial Designer–Manufacturer Collaboration Through CMM Data

Few things strain industrial designer manufacturer collaboration more than conflicting interpretations of accuracy. Designers see intent. Manufacturers see process limits. CMM data creates a shared, objective language between both sides.

Inspection reports enable fact-based root cause analysis, shifting discussions away from opinion and toward resolution. Instead of debating whether a part should work, teams can examine how it measures, where variation originates, and what design or process changes will have the greatest impact.

When designers engage with CMM data early, collaboration becomes proactive rather than reactive. Adjustments happen before tooling is finalized, not after production disruptions occur. This alignment improves program predictability, reduces redesign cycles, and protects launch timelines.

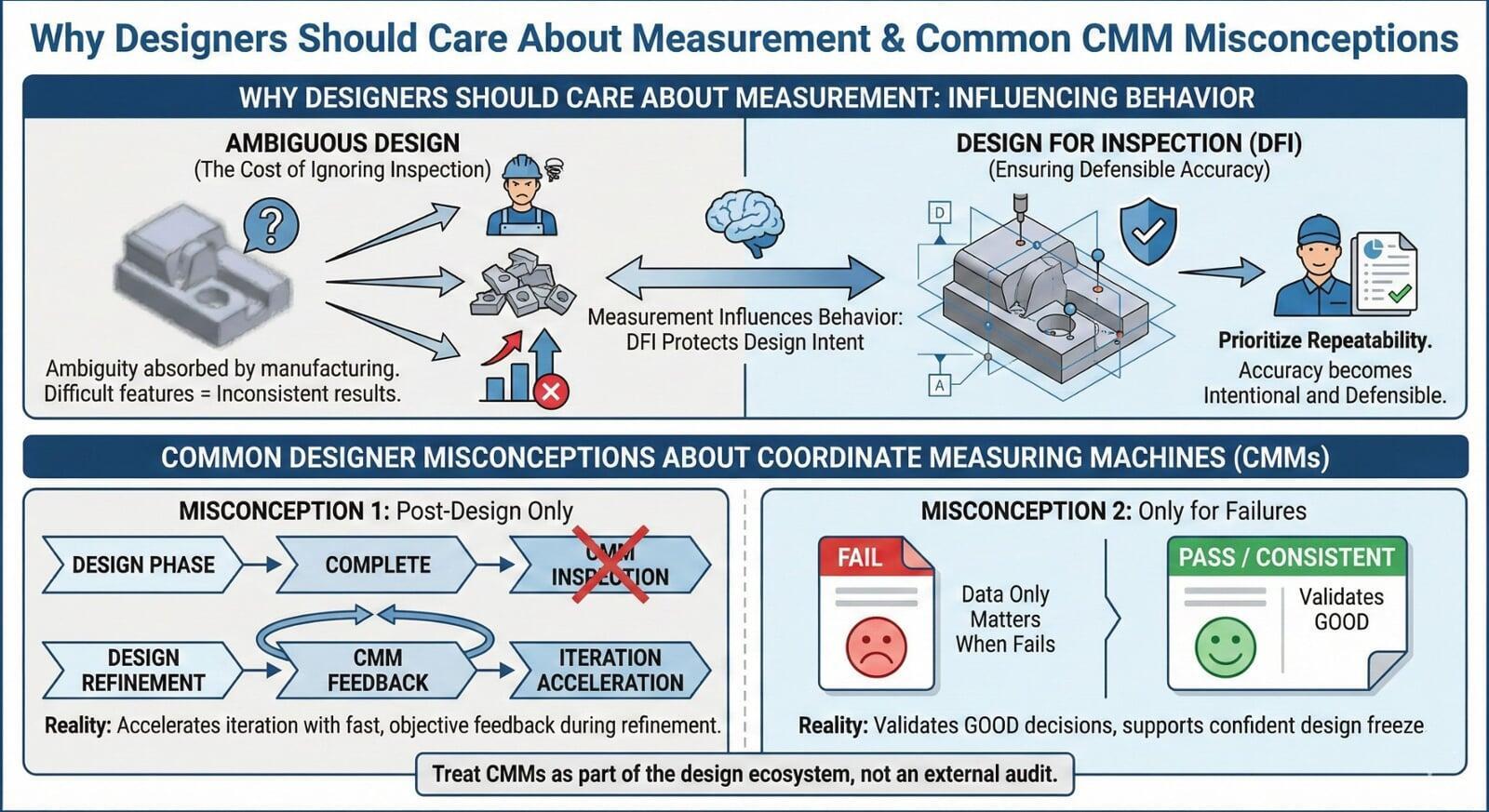

Why Designers Should Care About How Parts Are Measured

Measurement influences behavior. When designers ignore how a part will be inspected, the cost of ambiguity is absorbed by manufacturing, quality teams, and suppliers. Features that are difficult to probe or align lead to inconsistent inspection results—even when the part performs functionally.

CMMs expose these issues clearly. Designers who prioritize repeatability over theoretical accuracy create geometry that can be verified consistently. Designing with inspection in mind protects designers by ensuring that accuracy is defensible, not subjective, as production scales.

Common Designer Misconceptions About Coordinate Measuring Machines

Many designers assume CMMs are relevant only after design is complete. In reality, they accelerate iteration by providing fast, objective feedback during refinement. Another misconception is that CMM data matters only when something fails. Consistent measurement results validate good decisions and support confident design freeze milestones.

When designers treat coordinate measuring machines as part of the design ecosystem rather than an external audit, accuracy becomes intentional rather than accidental.

Trustbridge Tip: Great design starts with clear intent, but accuracy at scale depends on how well a design strategy anticipates real-world behavior. Tools like coordinate measuring machines help designers validate how geometry, tolerances, and datums behave outside of CAD—much like how flexible parts can fail in production even when they look perfect on screen. Understanding how parts deform, shift, or accumulate variation under real conditions gives designers the evidence they need to refine models before production. To see why parts that look ready in CAD still run into trouble on the shop floor and how designers can avoid those pitfalls, read our blog: Why Do Flexible Parts Fail in Production Even When They Look Perfect in CAD?

Conclusion

Accuracy is not created at inspection. It is designed in.

A coordinate measuring machine does more than verify dimensions. It reveals how design decisions interact with manufacturing reality. For designers, this insight strengthens design for manufacturability, improves how CAD is prepared for manufacturing, and reduces risk as products move from prototype to production.

Designers who engage with CMM data early replace assumption with evidence. They make earlier, better-informed decisions, reduce late-stage changes, and protect design intent all the way to scale.

If your designs look perfect in CAD but struggle to hold accuracy in production, the issue is rarely tooling or inspection alone. It is preventable visibility gaps.

Review CMM reports during prototype sign-off. Ask how parts are fixtured and measured. Design features so they can be probed repeatably. Align CAD, tolerances, and manufacturing reality before scale exposes the gaps.

Accuracy that survives production is not an accident. It is the result of designers who treat measurement feedback as a design input—not a post-design correction.

Frequently Asked Questions (FAQs)

1. What is a coordinate measuring machine, and why should designers care?

A coordinate measuring machine (CMM) is an inspection tool used to verify a part’s geometry against its design intent. Designers should care because CMM results reveal how well CAD models translate into real, manufacturable parts and where design assumptions break down.

2. When should designers start reviewing CMM data?

Designers should review CMM reports as early as prototype sign-off. Early feedback helps identify tolerance stack-ups, unstable datums, and features that are difficult to measure before those issues reach production.

3. How does CMM feedback support design for manufacturability?

CMM data highlights which dimensions are consistently hard to hold, which surfaces distort, and where machining variation occurs. This insight allows designers to refine tolerances, adjust features, and improve inspectability without compromising function.

4. What CMM information is most useful for designers?

The most valuable data includes positional accuracy, flatness, profile variation, and repeatability across multiple parts. Patterns in these results often point to design-related issues rather than machining errors.