From Concept to Production: Integrated Design Engineering

Whether you’re refining a prototype, redesigning a legacy part for cost savings, or starting with a napkin sketch, we plug in where you need us — and carry your design all the way through to production.

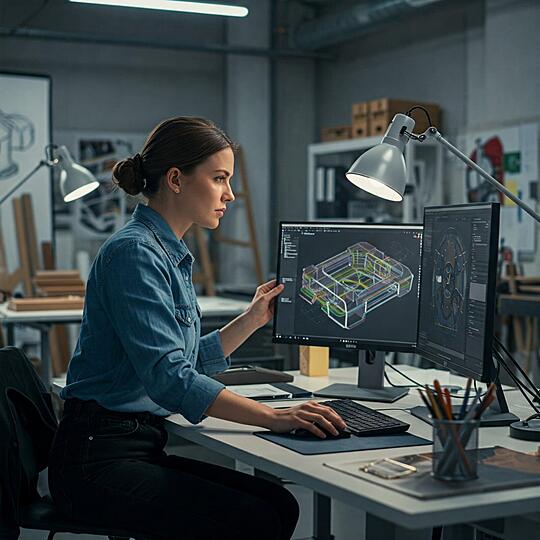

Our DFM Process

A collaborative process to refine your design for success.

Design Submission

You provide your CAD files and project goals. We'll sign an NDA to ensure your intellectual property is fully protected.

Expert Analysis

Our experienced engineers analyze your design for manufacturability, material selection, cost-drivers, and potential quality risk.

Actionable Report

We deliver a report with clear actionable recommendation to improve your design and prepare it for production.

A Perfect Design Isn't Always a Producible One.

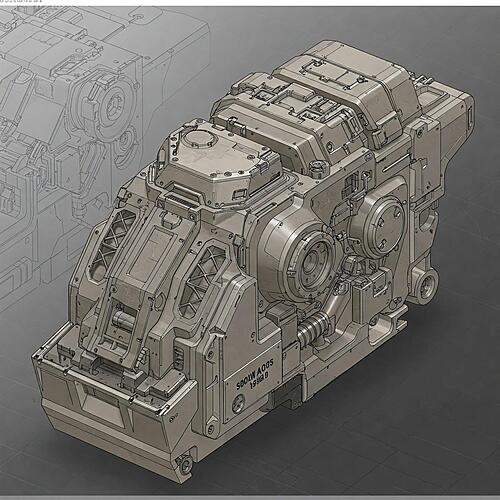

Unlock A Better Manufacturing Outcome

Reduce Production Cost

Accelarate Time to Market

Improve Product Quality

Ready to Optimize Your Design?

Let our experts review your project and provide the insights you need for a successful production run. Get started with a free, no-obligation DFM consultation.