Digital Procurement Tools: How Buyers Reduce Supplier Risk and Build Stronger Relationships

Buyers today operate in an environment where supplier complexity, global sourcing risks, and rising quality expectations intersect. Manual procurement processes that once felt manageable now create blind spots, delays, and hidden risk.

Digital procurement tools have therefore shifted from “nice-to-have” systems into core infrastructure—supporting risk control, accountability, and supplier decision-making.

For procurement leaders, technology is no longer optional. Digital platforms now anchor supplier qualification, compliance oversight, performance tracking, and lifecycle decisions in one connected system. Buyers who adopt the right tools gain visibility, consistency, and control across the supply base. Those who rely on spreadsheets and disconnected systems face higher exposure to quality failures, missed timelines, and compliance gaps as complexity grows.

Why Digital Procurement Tools Matter to Modern Buyers

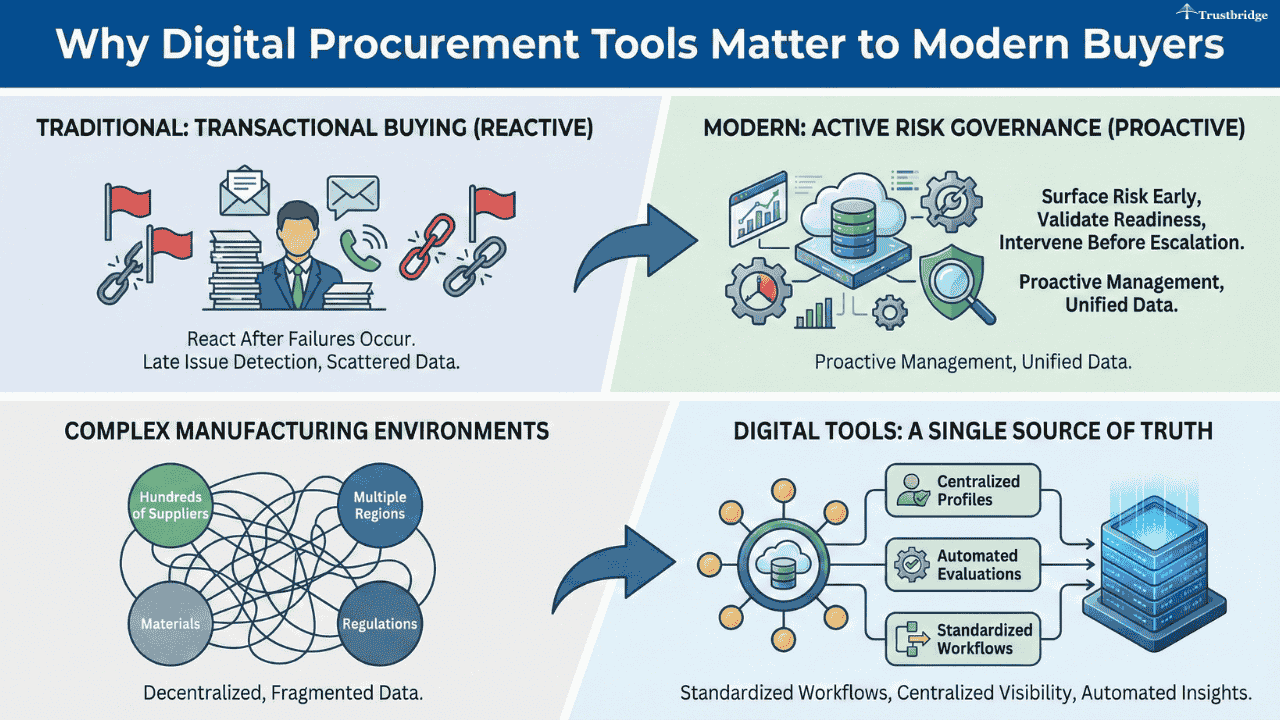

Digital procurement tools fundamentally change how supplier relationships are managed across the sourcing lifecycle. Instead of reacting after failures occur, teams can surface risk early, validate readiness, and intervene before issues escalate. This shift moves procurement from transactional buying to active risk governance.

In complex manufacturing environments, organizations may manage hundreds of suppliers across regions, materials, and regulatory regimes. Digital tools centralize supplier profiles, automate evaluations, and standardize workflows—creating a single source of truth.

Examples include supplier dashboards, automated risk scoring, compliance trackers, and approval workflows that allow teams to balance cost, quality, speed, and compliance without sacrificing one for another.

(Breaks long sentence, avoids repetition, adds concrete examples – KG2, KG3, KG4)

Digital Procurement Tools and Supplier Risk Management

Supplier risk management is one of procurement’s most critical—and most difficult—responsibilities. Risk rarely appears as a single failure; it accumulates through small gaps in visibility, documentation, and follow-through. Digital procurement tools expose these gaps early.

By integrating supplier data, performance history, and compliance status into a unified platform, teams gain real-time visibility into operational, quality, and delivery risk. This enables earlier corrective action, targeted supplier development, or proactive sourcing diversification.

Effective risk management depends on timely data, structured escalation paths, and consistent enforcement—capabilities that manual processes cannot sustain at scale.

Strengthening Supplier Compliance Through Technology

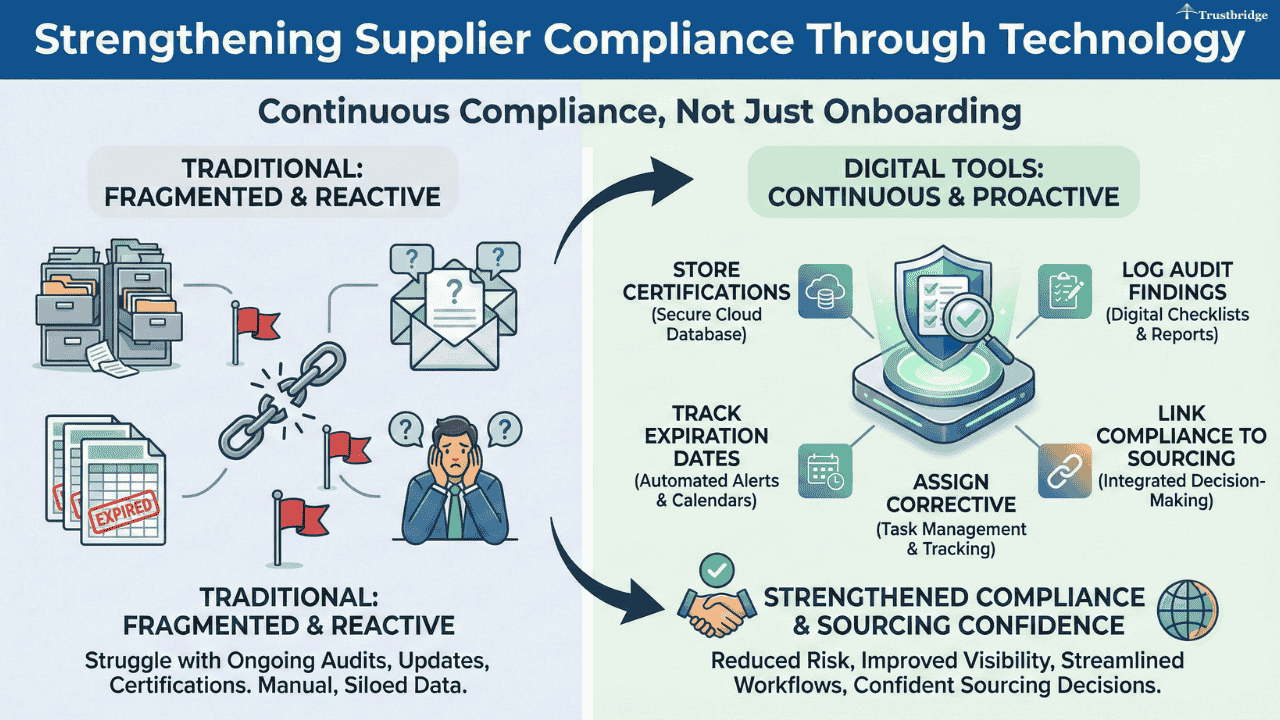

Supplier compliance no longer stops at onboarding. Maintaining compliance over time—across audits, certifications, regulatory updates, and internal standards—is where most organizations struggle. Digital procurement tools make continuous compliance possible.

These platforms store certifications, track expiration dates, log audit findings, assign corrective actions, and link compliance status directly to sourcing decisions.

Ask yourself:Would you rather discover a compliance lapse during an audit—or before it disrupts production?

When compliance is embedded into digital workflows, it stops being reactive and becomes operational discipline. The result is lower variability, stronger audit readiness, and fewer downstream disruptions that impact customers.

(Adds examples, reflection question, and completes the thought – KG5, KG6, KG7)

Managing the Production Part Approval Process (PPAP) Digitally

The production part approval process (PPAP) ensures suppliers can consistently produce parts to specification before full-scale production. When managed manually, PPAP files are often fragmented across emails, folders, and spreadsheets—creating launch risk. Digital procurement tools bring structure and traceability.

Digitized PPAP workflows standardize submission requirements, track approval status, enforce version control, and align engineering, quality, and suppliers. This reduces approval delays and prevents miscommunication that leads to rework or late corrections.

Digitizing PPAP accelerates launches while strengthening accountability across the supplier network.

Using Supplier Scorecards to Drive Accountability and Improvement

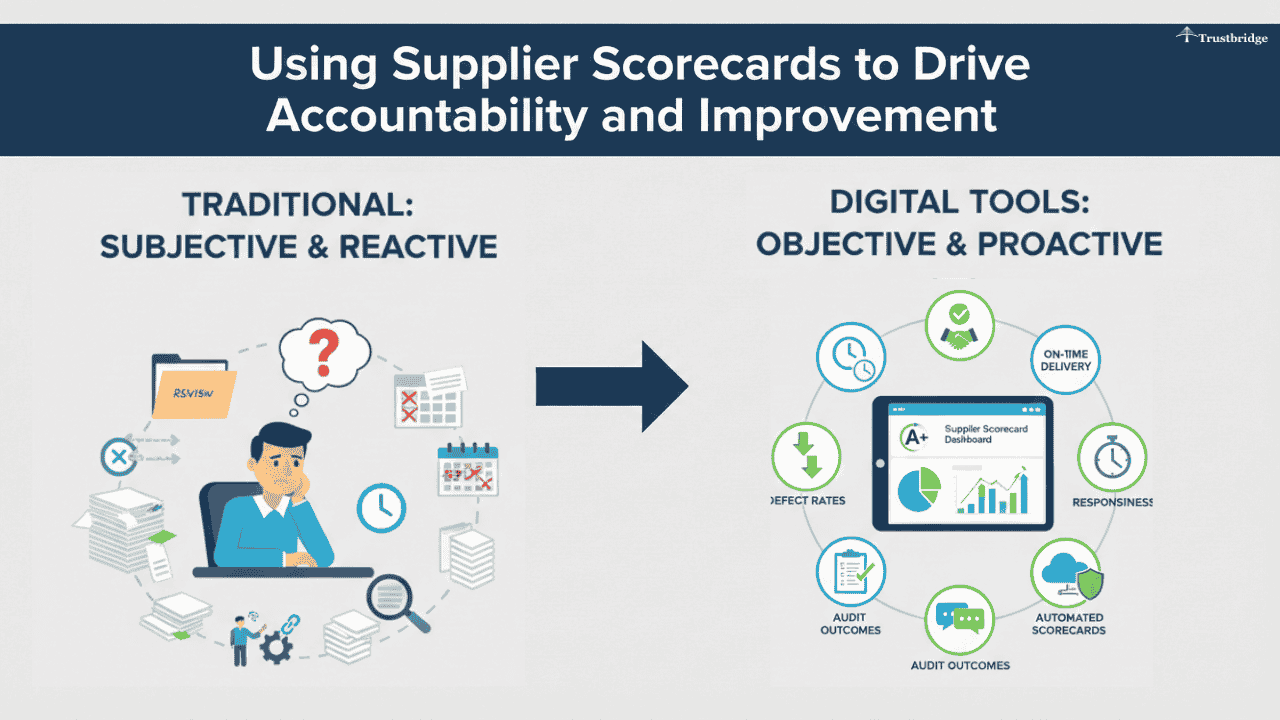

Supplier performance cannot improve without consistent measurement. Many buyers struggle with subjective reviews, outdated data, or post-incident evaluations. Supplier scorecards solve this by creating objective visibility.

Digital procurement tools automate scorecards using metrics such as on-time delivery, defect rates, corrective action cycle time, responsiveness, and audit outcomes.

With real-time visibility, teams detect trends early—before missed shipments or recurring quality escapes escalate. This shifts supplier conversations from reactive blame to proactive improvement and enables smarter allocation of future business.

(Adds pain point, metrics, and strategic impact – KG8, KG9, KG10, KG11)

Digital Tools as Enablers of Supplier Lead Time Reduction

Supplier lead time reduction is not achieved through pressure alone. It requires visibility into constraints, communication breakdowns, and execution gaps. Digital procurement tools illuminate where delays originate.

By integrating order status, performance data, and communication history, buyers and suppliers can collaborate to remove bottlenecks and stabilize timelines. Predictable lead times improve production planning, reduce inventory buffers, and lower total cost.

When expectations and execution are aligned digitally, lead time reduction becomes a shared objective—not a one-sided demand.

Building Stronger Buyer–Supplier Relationships Through Transparency

Trust is built on clarity, consistency, and fairness. Digital procurement tools create shared visibility into expectations, metrics, and compliance requirements—eliminating ambiguity.

Advanced analytics, trend dashboards, and shared performance views help suppliers understand how success is measured and where improvement matters most. This transparency reduces disputes, accelerates issue resolution, and lowers relationship friction.

Stronger trust directly improves agility, cost control, and long-term supplier commitment.

(Adds tools, cost/agility impact, and strengthens trust angle – KG12–KG15)

Integrating Digital Procurement Tools Into Buyer Decision-Making

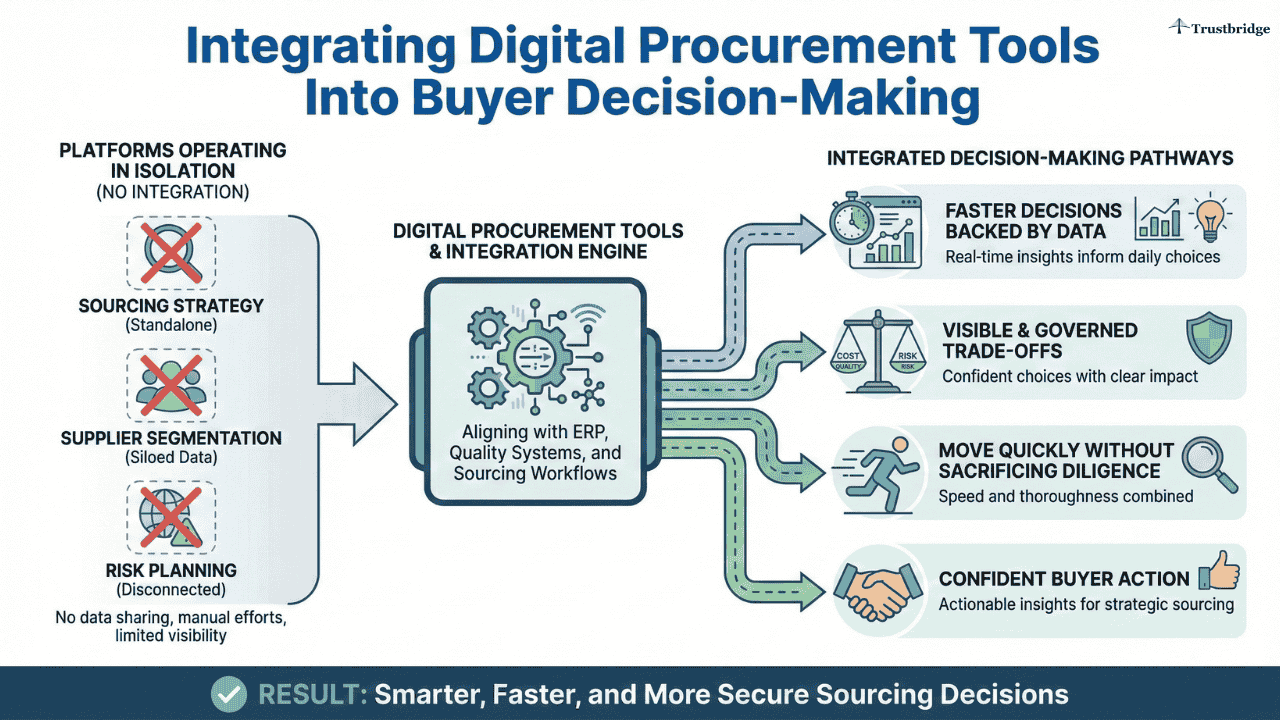

The real value of digital procurement tools emerges when insights inform daily decisions—not when platforms operate in isolation. Integration with sourcing strategy, supplier segmentation, and risk planning is critical.

When aligned with ERP, quality systems, and sourcing workflows, digital tools enable faster decisions backed by data. Buyers can move quickly without sacrificing diligence, confident that trade-offs between cost, quality, and risk are visible and governed.

Technology amplifies buyer judgment—it does not replace it.

Common Pitfalls Buyers Should Avoid When Adopting Digital Procurement Tools

Technology alone does not solve procurement challenges. Poor implementation can create a false sense of control while risks persist. Treating digital procurement tools as software installs—rather than organizational systems—is a common failure.

Without clear ownership, standardized workflows, and supplier engagement, platforms underperform. Buyers should define success metrics, enforce consistent use, and actively onboard suppliers into digital processes.

The goal is simplification—not digitized complexity.

Trustbridge Tip: In small batch manufacturing, flexibility alone is not enough—buyers prioritize process control and repeatability. CNC router machining is often how OEMs evaluate new suppliers, focusing on quoting discipline, programming stability, and consistent output at low volumes. Shops that deliver reliable CNC machining services and predictable CNC quote turnaround time consistently stand out as lower-risk partners. To see how buyers evaluate CNC router suppliers, read our guide: Buyer’s Guide to CNC Router Machining: How to Select the Right Supplier for Precision Machined Parts.How to Select the Right Supplier for Precision Machined Parts.

The Strategic Advantage of Digitally Enabled Procurement

Digitally enabled procurement delivers a measurable competitive advantage. Integrated platforms connect sourcing, quality, compliance, and supplier performance into one decision system.

This integration improves decision speed, strengthens risk awareness, and enables proactive responses to disruption.

Actionable tip: Start by integrating compliance tracking and supplier performance data into sourcing decisions—where risk has the highest impact.

As supply networks grow more complex, technology becomes the only scalable way to maintain control without slowing innovation.

(Adds integration examples, decision impact, warning tone, and action – KG16–KG19)

Conclusion

Digital procurement tools are no longer operational conveniences—they are strategic assets. By digitizing supplier compliance, PPAP workflows, scorecards, and risk management, buyers gain the visibility and control required for confident sourcing.

When used effectively, technology enables supplier lead time reduction, strengthens accountability, and transforms procurement into a proactive value driver. Buyers investing today are building resilient, transparent, and high-performing supply chains prepared for future disruption.

Strengthen Your Supplier Strategy With Digital Procurement Tools

If you manage supplier selection, performance, or risk, now is the time to modernize. Digital procurement tools deliver faster approvals, stronger compliance, reduced surprises, and better supplier accountability.

By integrating procurement platforms with sourcing, quality, and operations, buyers gain a competitive edge—moving faster, reducing risk, and building supplier relationships that scale.

Frequently Asked Questions (FAQs)

1. What are digital procurement tools, and how are they different from traditional procurement systems?

Digital procurement tools go beyond purchase orders and price comparison. They centralize supplier data, automate compliance tracking, manage PPAP workflows, monitor performance through scorecards, and surface risk early. Unlike spreadsheets or disconnected systems, they provide structured, real-time visibility across the entire supplier lifecycle.

2. How do digital procurement tools help buyers reduce supplier risk?

These tools reduce risk by integrating performance history, compliance status, and operational data into one platform. Buyers can identify early warning signals—such as declining delivery performance or expiring certifications—and intervene before issues escalate into production delays or quality failures.

3. Can digital procurement tools improve supplier compliance beyond onboarding?

Yes. Digital tools continuously track certifications, audit findings, corrective actions, and regulatory requirements. This ensures compliance is maintained throughout the relationship, not just verified at onboarding, reducing audit risk and downstream disruptions.

4. How do digital procurement tools support the Production Part Approval Process (PPAP)?

By digitizing PPAP, buyers can standardize submissions, track approval status, enforce version control, and align engineering, quality, and suppliers. This reduces launch delays, prevents documentation gaps, and strengthens accountability before full-scale production begins.