Best CAD CAM Software for Designers: How to Pick the Right Tool for Manufacturing

Choosing the right CAD CAM software can make or break your product development workflow. For many designers, CAD feels familiar, but CAM often feels “too technical” or “something only machinists need.” The truth is, understanding both is essential if you want your designs to be manufactured accurately, efficiently, and without costly changes. The software you choose affects everything from how well your ideas are communicated to machinists, to how stable the part will be during machining, to how quickly your supplier can deliver it.

In this blog, we break down what designers need to know about CAD CAM tools in simple, easy language. By the end, you’ll know exactly how to select a tool that supports manufacturability, helps you avoid machining mistakes, and gives your suppliers the clarity they need to produce high-quality parts.

Why CAD CAM Software Matters for Designers

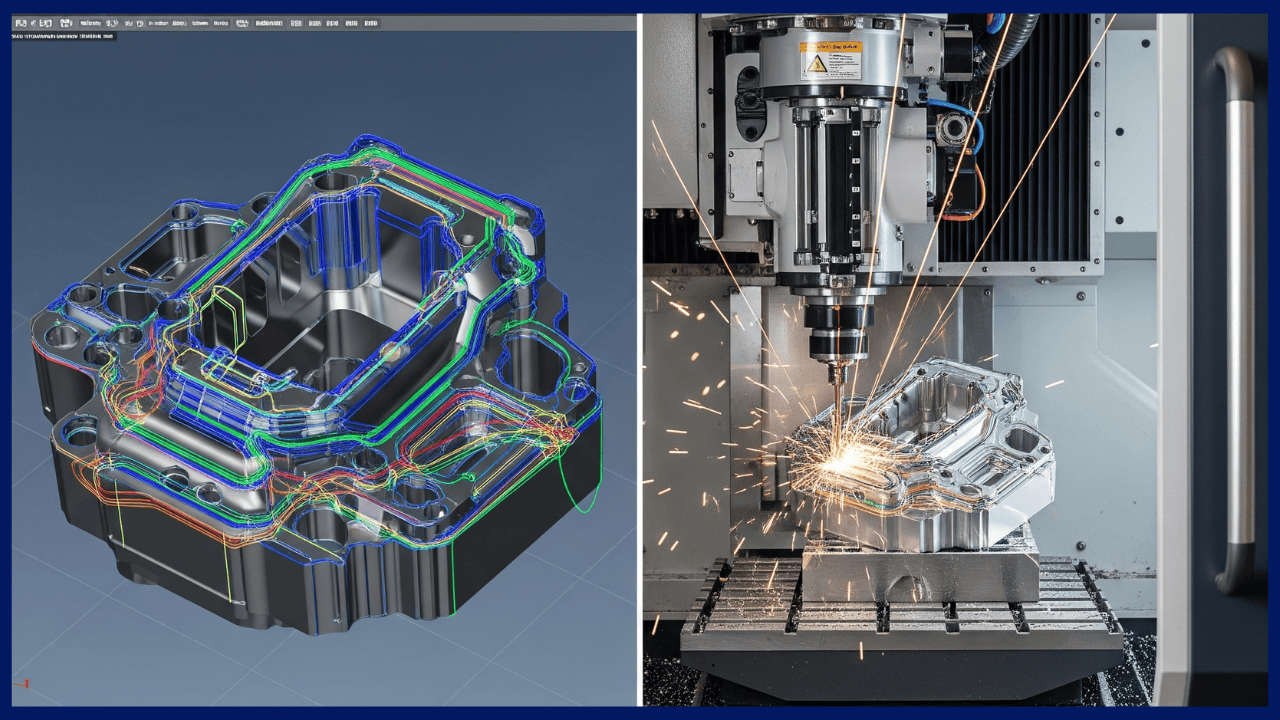

The quality of a manufactured part starts with the digital model. When designers use the right CAD CAM software, they gain visibility into how the part will be machined, how the CNC tool will move, and what limitations might impact accuracy. This helps prevent last stage changes that waste time and money. It also ensures that features like fillets, counterbore holes, and chamfers are created in ways machinists can cut.

Here's a simple scenario - imagine you are designing a deep cavity with sharp internal corners. It looks clean in CAD, but CAM simulation instantly shows that no CNC tool can physically reach those corners. By catching this early, you avoid a full redesign later and keep the project on schedule.

When the software supports both design and machining, your part becomes easier to produce, resulting in fewer errors and smoother production runs.

CAD vs CAM: What Designers Must Understand

Designers often focus heavily on CAD and overlook CAM, assuming it’s mainly for machinists. But CAM plays a major role in manufacturability.

Good CAD CAM software combines modeling and toolpath planning so you can see how your design will behave on real machines. You can preview whether an undercut can be reached, whether a feature requires climb milling vs conventional milling, and whether your dimensions are realistic for CNC machining. With this visibility, you reduce back-and-forth communication and help the machinist set up the part correctly the first time.

How to Choose the Best CAD CAM Software as a Designer

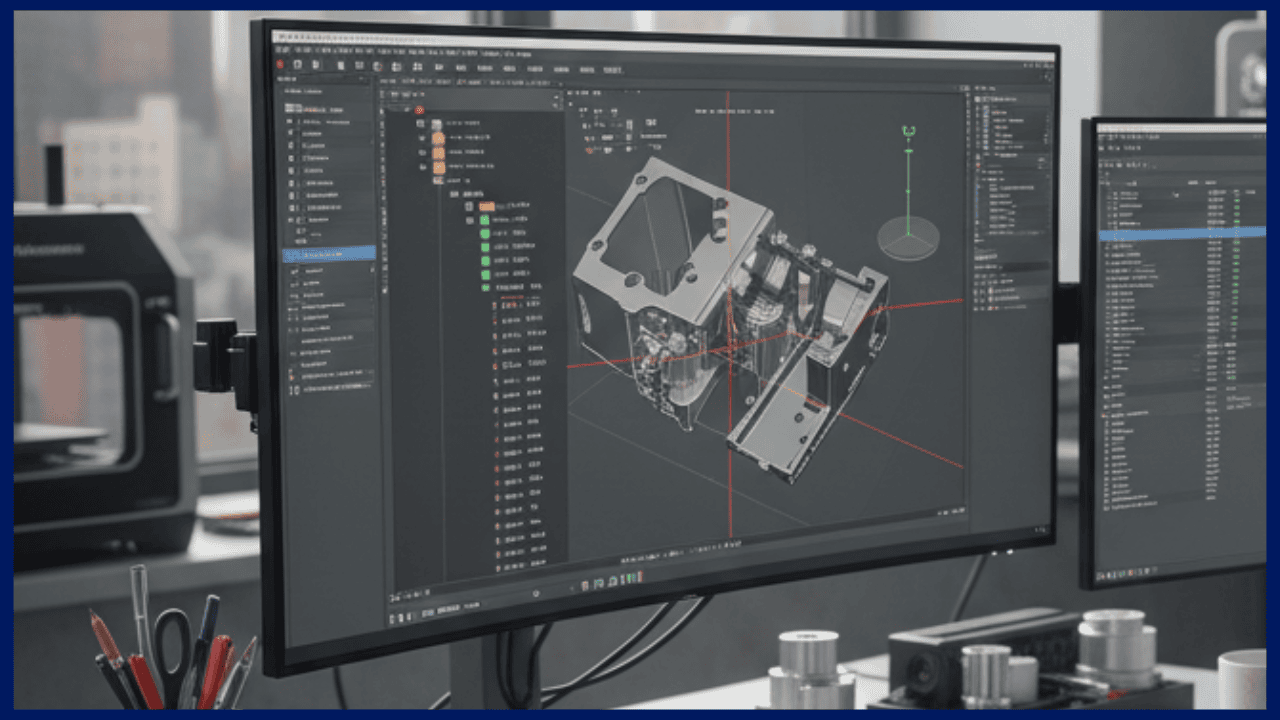

Selecting the right CAD CAM software starts with understanding your workflow. The ideal tool should support modeling, simulation, toolpath creation, and simple file sharing.

If you frequently collaborate with machine shops or engineering teams, choose software with strong integration between CAD design and CAM programming, ensures your files translate correctly into CNC machine and programming operations.

A good system helps you see which CNC tool sizes can reach your features, whether your tolerances are realistic, and how many setups the machinist will need. These insights make your designs easier and cheaper to produce.

Preparing CAD for Manufacturing with CAD CAM Software

Using CAD CAM software makes it much easier to prepare CAD for manufacturing. As you refine your model, the software can highlight areas where machining might be difficult. Toolpath previews help you identify thin walls, deep cavities, or areas that may require special tooling.

This early visibility is crucial when moving from prototype to production. Stable toolpaths and clean geometry lead to predictable machining, faster quoting, and fewer production delays. When your CAD file is prepared correctly, machinists can work more efficiently and confidently.

Trustbridge Tip: Choosing the right CAD CAM software is only part of improving manufacturability. The bigger impact comes from how well your design decisions align with how parts are actually made. Even strong CAD models can lead to cost overruns if features are hard to machine, toolpaths are unstable, or material behavior isn’t fully considered. This is why understanding design for manufacturability (DFM) is essential it helps you reduce machining time, avoid rework, and keep production predictable. To see how DFM directly reduces cost without compromising quality, explore our full guide: How Can Design for Manufacturability Cut Production Costs Without Compromising?

CAD CAM Software and Design for Manufacturability

A major goal of design for manufacturability is ensuring the part can be machined easily and accurately. CAD CAM software helps you understand how different materials behave during machining.

For example, plastics with a low melting point require slower cutting speeds to avoid melting. Materials such as Teflon material, PTFE CNC, and Teflon CNC may deform if toolpaths aren’t optimized. Metals that will become anodized metal need thickness adjustments in CAD so final dimensions are correct after finishing. Even elastomers like thermoplastic elastomer material require special consideration due to their flexibility.

Understanding these details early allows you to design parts that are easier and more cost-effective to produce.

Improving Designer–Manufacturer Collaboration

Good communication between designers and manufacturers reduces errors, speeds up quoting, and improves part quality. When designers use CAD CAM software, both sides work from the same visual and machining data. Manufacturers no longer have to guess what you want, they can see it directly.

This is a key part of strong industrial designer–manufacturer collaboration. Machinists can even use a coordinate measuring machine to inspect your part based on the same CAD tolerances you created. Clearer handoffs mean fewer revisions, fewer surprises, and faster delivery times.

Conclusion

Choosing the best CAD CAM software is not just about modeling it’s about improving manufacturability, reducing risk, and ensuring your designs can be produced reliably. When CAD and CAM are unified, you get clearer communication, fewer manufacturing problems, and smoother transitions from prototype to final production.

By using the right tool and understanding machining limitations, you help your manufacturers deliver accurate, repeatable results every time. Good software doesn’t just support your design, it supports the entire journey from idea to finished part.

Empower your design team with intelligent sourcing tools, real-time spend insights, and data-driven decision-making. Visit Trustbridge.pro to explore designer-focused resources, success stories, and solutions that help manufacturing teams design and lead with confidence.

Frequently Asked Questions:

1. Why is CAD-CAM software important for designers, not just machinists?

Because manufacturability starts at the design stage. With CAD-CAM, designers can see how CNC tools will cut the part, identify limitations early, and avoid costly redesigns. It ensures your design can be machined the way you intended.

2. How does CAD-CAM software help avoid machining issues?

CAD-CAM simulations reveal problems such as unreachable undercuts, thin walls, tight radii, or features requiring climb milling vs conventional milling. This prevents errors before files reach the machinist and reduces back-and-forth communication.

3. What features should designers look for when choosing CAD-CAM software?

Look for a tool that integrates CAD modeling, CAM simulation, toolpath previews, tolerance control, and easy file export. This ensures your design translates correctly into CNC machine and programming operations without mistakes.