Join the Trustbridge Network: Supplier Qualification & Onboarding

At Trustbridge, we deliver manufacturing excellence by partnering only with suppliers who meet our high standards — for craftsmanship, communication, and consistency. Our customers rely on us to match them with vetted, trustworthy production partners, and we take that responsibility seriously.

Our Supplier Qualification & Onboarding process is how we ensure every partner in our network can deliver quality parts on time, every time — whether it's a prototype, a full production run, or a complex, multi-process project.

If you're a reliable, high-performing shop that wants to work with great customers and a smart, low-friction workflow, we’d love to hear from you.

Our Supplier Vetting Process

Why Join the Trustbridge Network?

Projects Screened by Engineers: Every job is reviewed by our internal team before it reaches you.

Fewer Quotes, Higher Win Rate: We send jobs only to qualified suppliers — no open bidding free-for-alls.

Real Customers, Real Relationships: Our clients range from startups to enterprise manufacturers — and many prefer to build long-term relationships with trusted shops.

Low Overhead: No subscription fees. No bidding platform noise. Just clean, relevant opportunities.

Support When You Need It: Our team stays involved to keep projects on track and advocate for both customer and supplier success.

Ready to Get Started?

If you're a top-tier supplier who wants better projects, fewer headaches, and more meaningful customer relationships — let's talk.

Explore Related Services

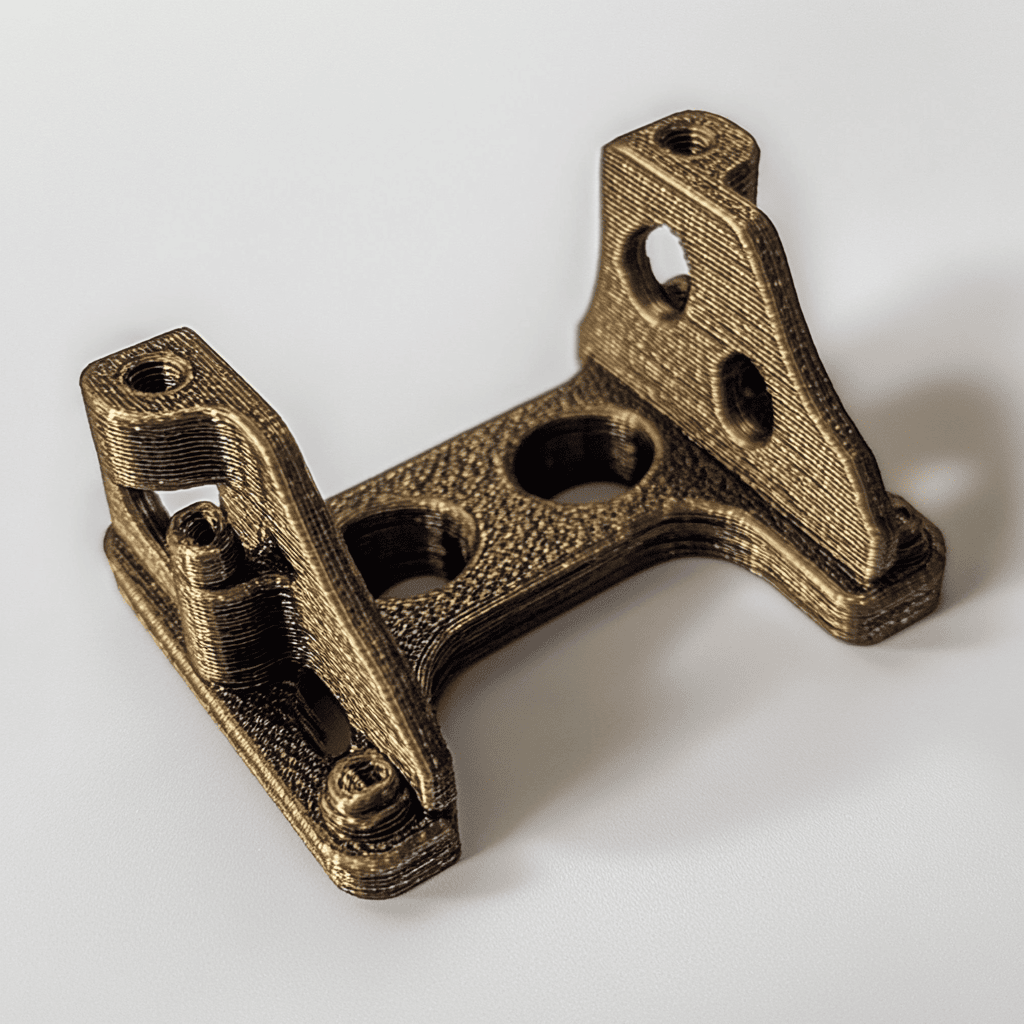

3D Printing

Rapid, cost-effective prototyping and low-volume production with complex geometries and minimal tooling.

Sheet Metal Fabrication

Cut, bend, and assemble custom enclosures, brackets, and panels — scalable from prototypes to full production runs.

Injection Molding

High-volume plastic part production with consistent quality, fast cycle times, and low per-unit cost once tooled.