How It Works For Suppliers: Join The Trustbridge Manufacturing Network

At Trustbridge, we’re not a job board or auction site. We’re a strategic sourcing partner that connects vetted manufacturers with serious customers product teams who care about quality, reliability, and long-term relationships. If you're a high-performing shop that wants a steady flow of qualified leads, clean files, and a customer relationship that respects your time and expertise, you're in the right place.

What Is Trustbridge?

We’re a modern sourcing platform that bridges the gap between engineers and manufacturers. Customers from startups to global OEMs submit parts to Trustbridge for prototyping or production. Our in-house engineering team reviews the request, selects the right manufacturing process, and then matches the project to qualified suppliers in our network.

You don’t have to fight through a feed of low-quality RFQs. We send the right jobs, directly to the right shops based on capabilities, materials, certifications, and past performance.

What It’s Like to Work With Us

What’s the First Step?

Apply to Join the Network — Fill out a short form and tell us about your shop

Technical Review — We’ll schedule a brief intro and evaluate your capabilities

Sample Project or Capability Match — We may route a test project or request sample parts

Onboarding — You’ll get access to your supplier profile and quoting workflow

You’ll only receive jobs that match your capabilities. No spam. No pressure to quote everything. Just real opportunities with real engineering teams behind them.

Interested in Working Together?

Let’s see if we’re a fit. We’re always looking for great partners who love solving real-world manufacturing challenges and delivering exceptional work.

Explore Related Services

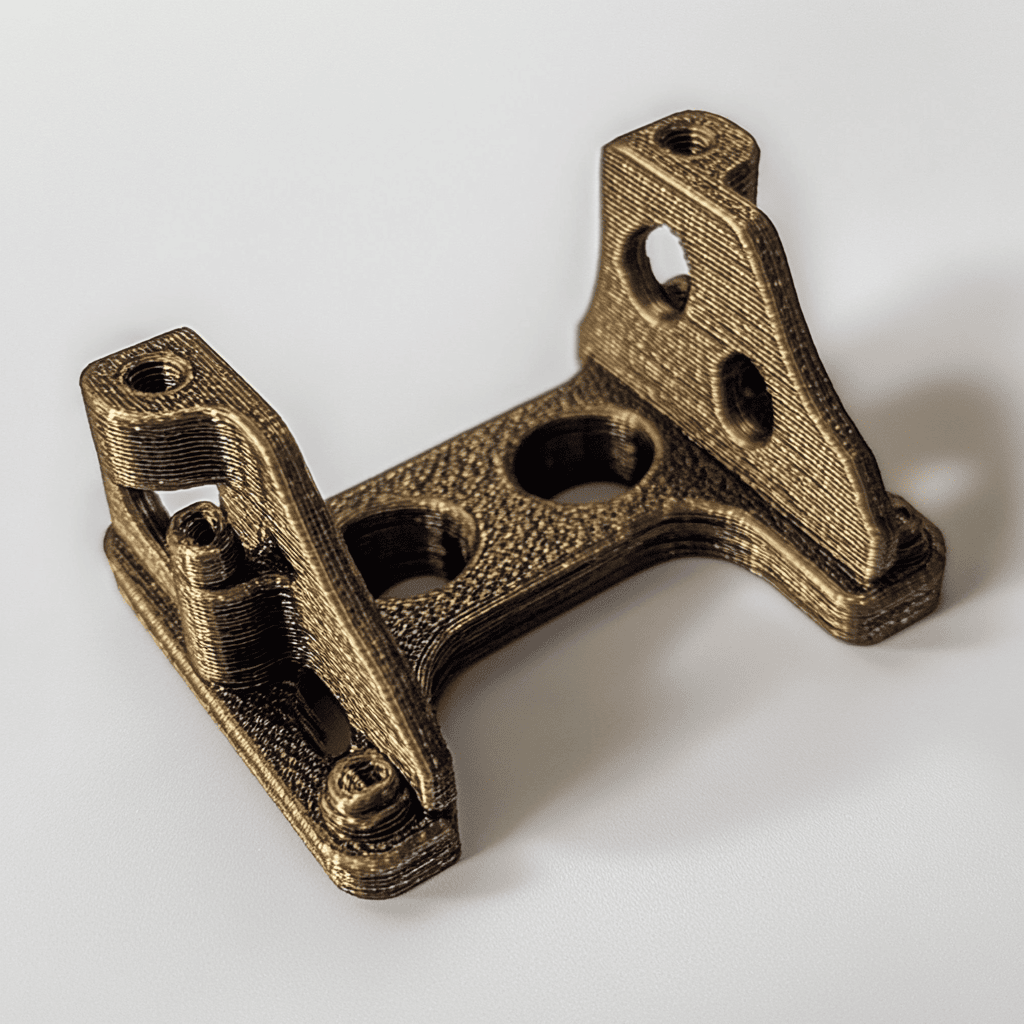

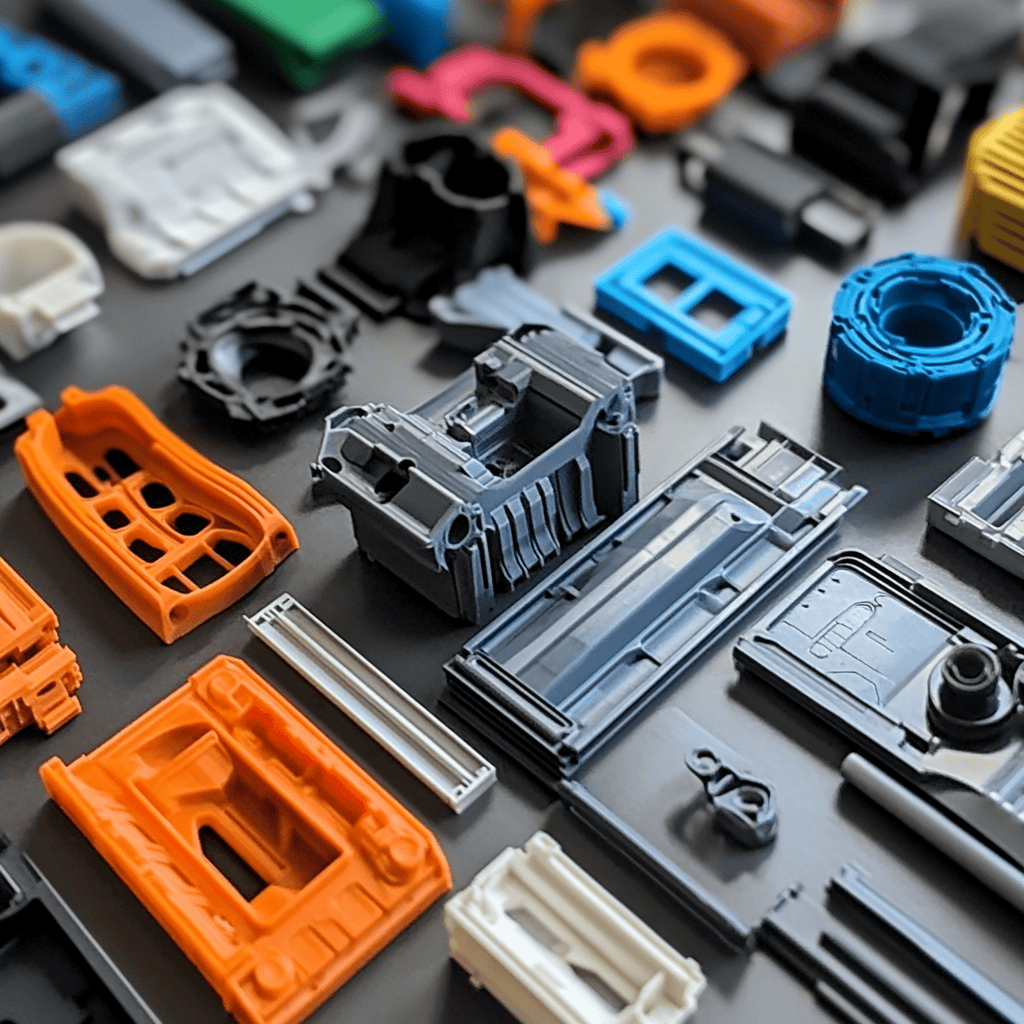

3D Printing

Rapid, cost-effective prototyping and low-volume production with complex geometries and minimal tooling.

Sheet Metal Fabrication

Cut, bend, and assemble custom enclosures, brackets, and panels — scalable from prototypes to full production runs.

Injection Molding

High-volume plastic part production with consistent quality, fast cycle times, and low per-unit cost once tooled.