Insights

For Buyers Procuring POM, How Can You Reduce Risk When Sourcing for Long-Term Production?

February 03, 2026 07:10 AM - Comment(s)

Learn how buyers assess POM material for strength, machinability, compliance, PPAP readiness, and supplier risk to ensure long-term production performance.

How Is AI in Manufacturing Redefining Supplier Performance and Buyer Expectations?

February 02, 2026 07:04 AM - Comment(s)

Discover how AI in manufacturing is transforming supplier operations through smarter CNC machining, faster quotes, predictive quality inspection, and stronger supplier relationships.

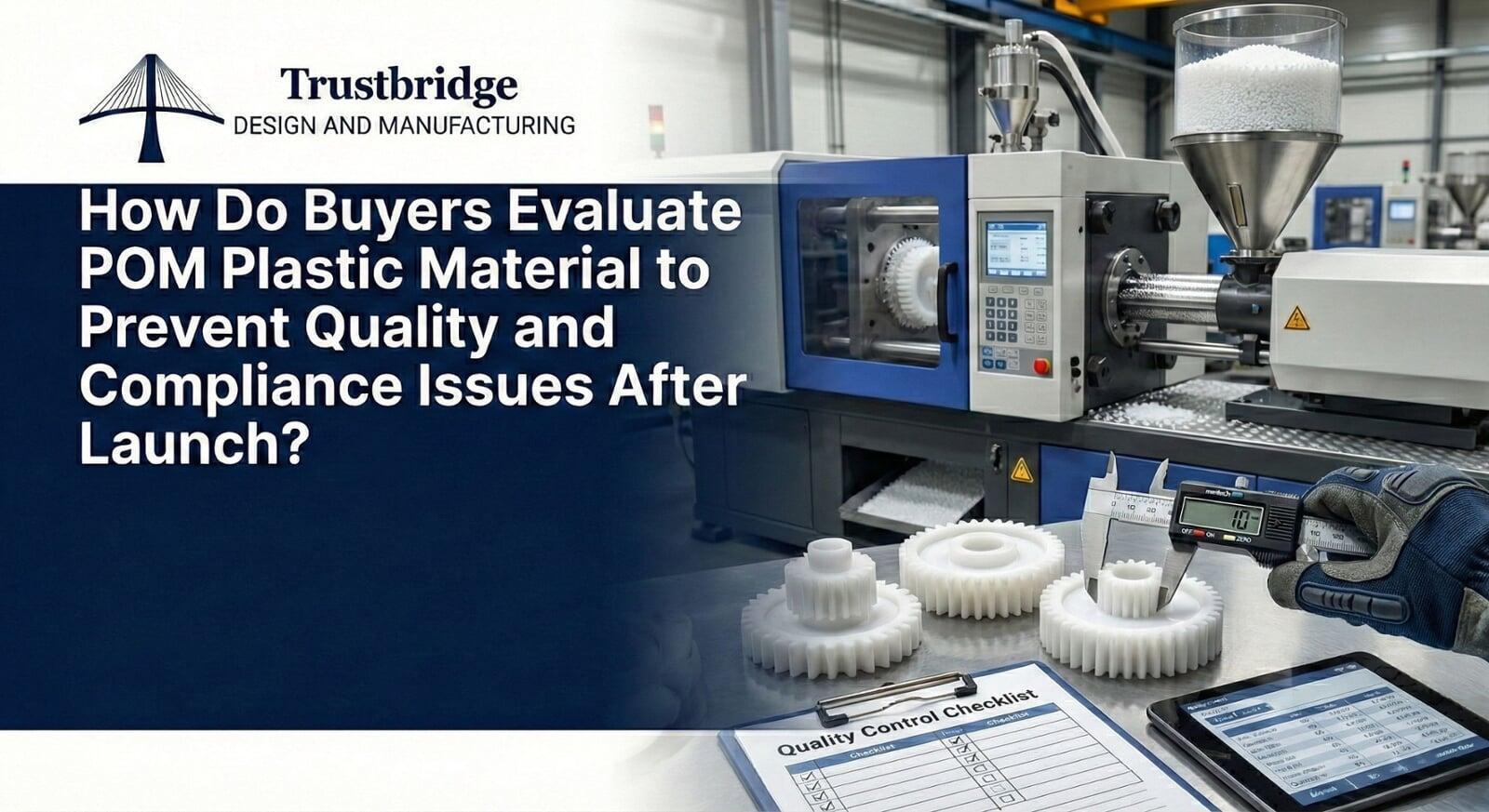

How Do Buyers Evaluate POM Plastic Material To Prevent Quality and Compliance Issues After Launch?

January 30, 2026 07:20 AM - Comment(s)

Learn how buyers evaluate POM plastic material for quality, compliance, PPAP readiness, and supplier performance to reduce risk in OEM manufacturing.

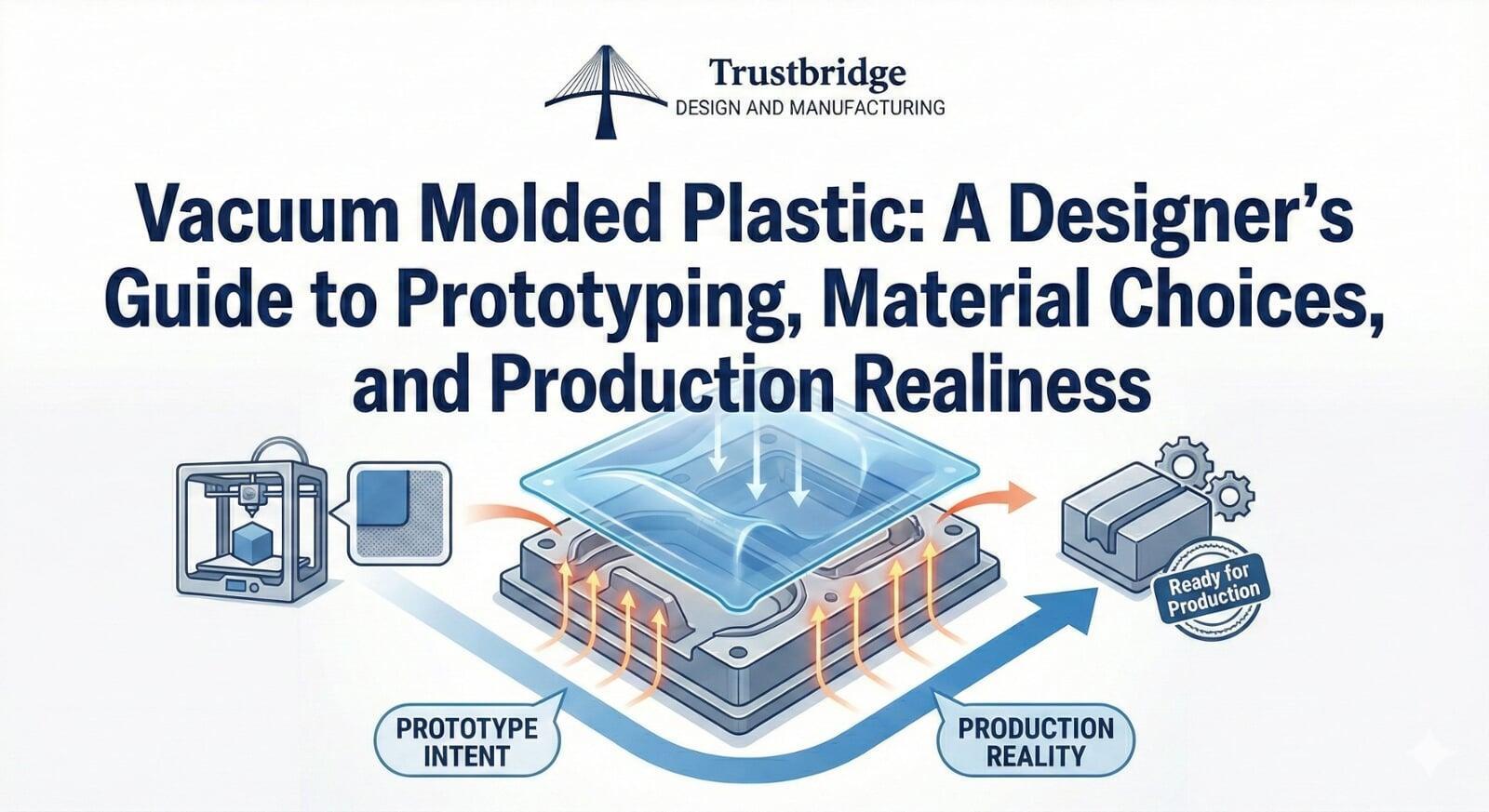

How Does Vacuum Molded Plastic Help Designers Identify Production Risks Early?

January 30, 2026 07:14 AM - Comment(s)

Learn how vacuum molded plastic helps designers validate geometry, materials, and manufacturability before moving from prototype to production.

Why Do Anodized Metal Finishes Reveal Supplier Process Control Issues So Quickly?

January 27, 2026 02:34 PM - Comment(s)

Anodized metal quality depends on supplier process control. Learn how buyers use finish consistency to evaluate manufacturability, approvals, and production readiness.

Categories

- Uncategorized

(11)

- technology

(3)

- Design

(26)

- Business Strategy

(2)

- Procurement

(23)

- Manufacturing

(2)

- Supplier

(20)