What Is a Plasma Cutter? How Plasma Cutting Is Used in Industrial Metal Fabrication

In modern industrial metal fabrication, speed, precision, and scalability are critical to meeting OEM and Tier-1 production demands. One technology that continues to play a vital role across fabrication shops is plasma cutting. To understand where plasma cutting fits in today’s manufacturing ecosystem, suppliers must first understand what a plasma cutter is, how it works, and how it supports compliant, production-ready workflows.

Plasma cutting is widely used in custom manufacturing, rapid prototyping, secondary operations on die cast metal, and high-throughput fabrication environments where efficiency and consistency matter.

Industries such as automotive chassis manufacturing, construction equipment fabrication, shipbuilding, and structural steel processing rely heavily on plasma cutting to meet tight delivery schedules while controlling costs.

For example, many automotive and construction suppliers rely on plasma cutting to shorten lead times without increasing production costs.

This article breaks down plasma cutting from a supplier’s perspective, including its role alongside CNC water jet cutting and its relevance to quality systems like the PPAP process and the part production approval process.

What Is a Plasma Cutter and How Does It Work?

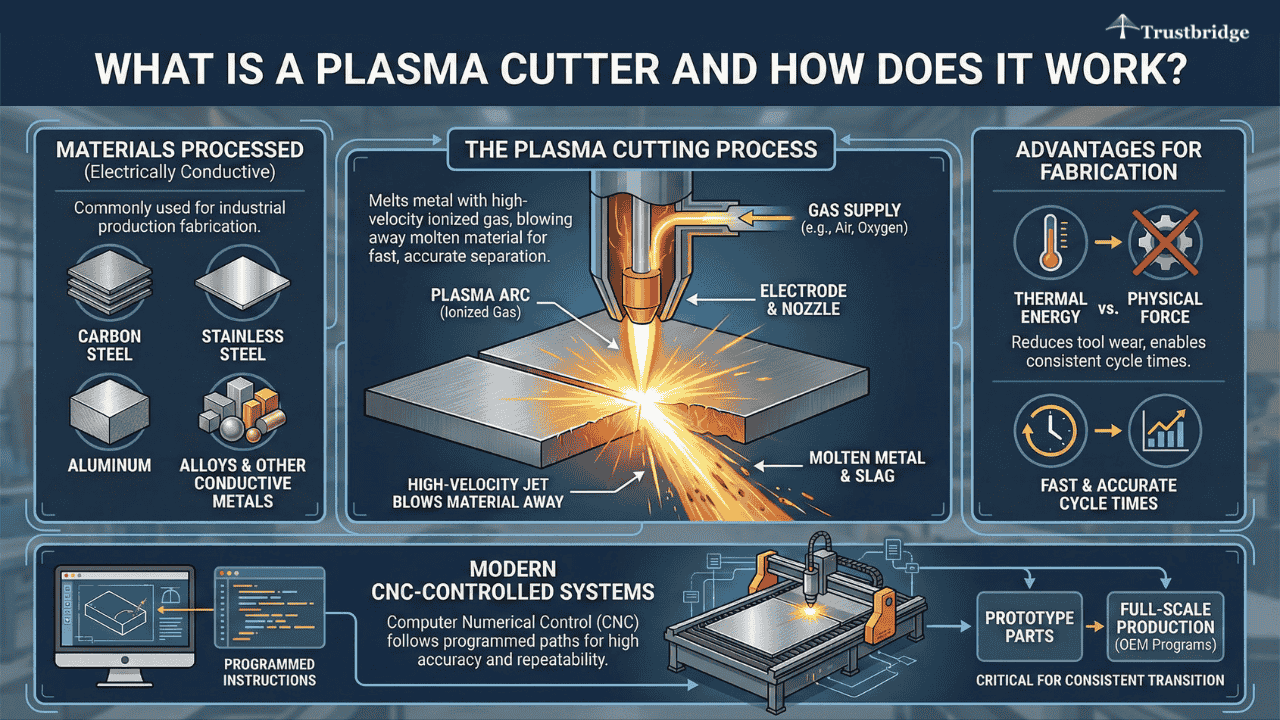

A plasma cutter is an industrial cutting tool that uses a high-velocity jet of ionized gas called plasma to cut electrically conductive metals. The plasma arc melts the metal while simultaneously blowing molten material away from the cut path, resulting in fast and accurate separation.

From a fabrication standpoint, plasma cutters are valued for their ability to process carbon steel, stainless steel, aluminum, and other conductive alloys commonly used in industrial production. Unlike mechanical cutting, plasma cutting relies on thermal energy rather than physical force, which reduces tool wear and helps suppliers maintain consistent cycle times.

Modern plasma cutting systems are often CNC-controlled (computer numerical control), meaning the cutting process follows programmed instructions for accuracy and repeatability. This repeatability is critical during the transition from prototype parts to full-scale production under OEM programs.

Why Plasma Cutting Matters in Industrial Metal Fabrication

Plasma cutting is not simply a cutting method; it is a productivity enabler in industrial fabrication environments. Suppliers rely on plasma cutting to meet aggressive lead times while maintaining part consistency and quality.

Speed and Scalability in Custom Manufacturing

In custom manufacturing, plasma cutting allows suppliers to adapt quickly to design changes or customer revisions. Whether producing short-run prototypes or medium-volume production parts, plasma systems handle varying material thicknesses and geometries without extensive retooling.

For instance, a contract manufacturer supporting both construction and agricultural equipment OEMs can use the same plasma cutting system across multiple product lines, improving shop flexibility and asset utilization.

Cost Efficiency for Production-Oriented Suppliers

Compared to laser cutting, plasma cutting offers lower upfront equipment costs while still delivering industrial-grade performance. This makes plasma cutting attractive for suppliers balancing capital investment with production capability.

For thicker metals, plasma cutting often delivers faster cut speeds and lower operating costs, making it ideal for structural components and fabricated assemblies used in heavy equipment and infrastructure projects.

Plasma Cutting vs Water Jet Cutting: Which Is Right for Your Needs?

Suppliers often compare plasma cutting with CNC machine water jet cutting when selecting the right process for production programs. While both technologies are widely used, the decision usually comes down to cost, speed, and material sensitivity.

Material Thickness and Heat Considerations

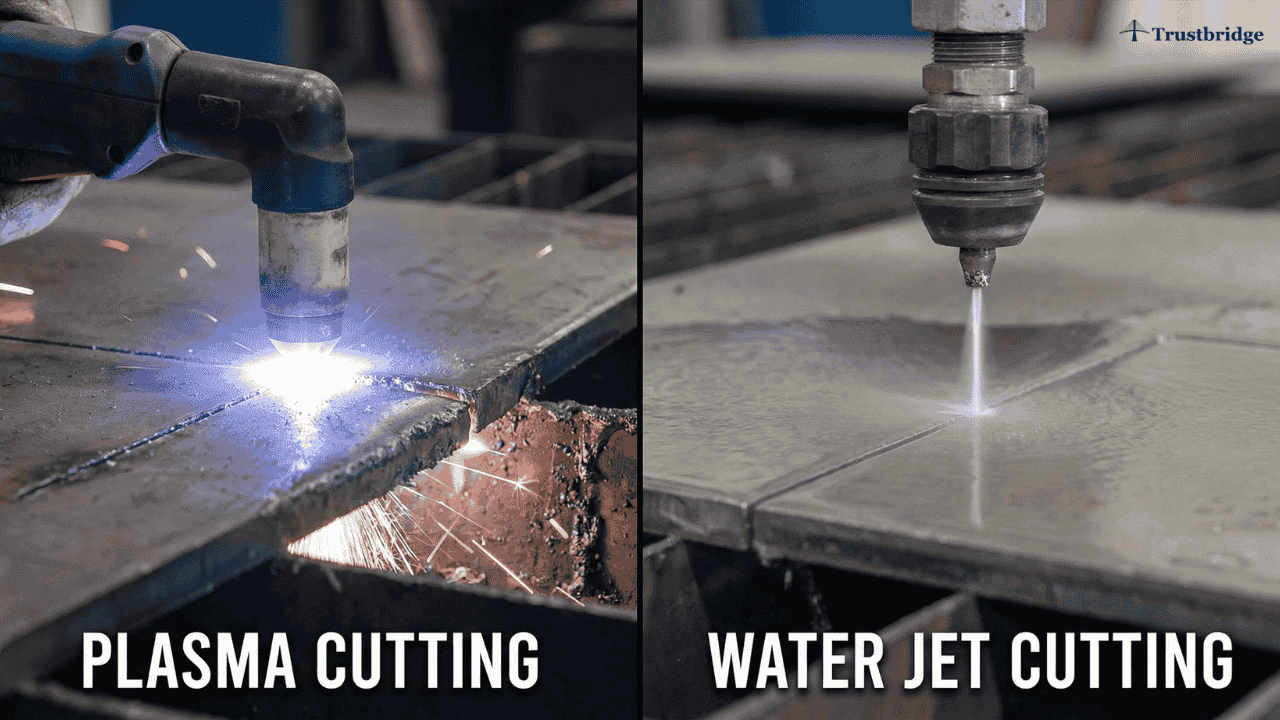

Plasma cutting is a thermal process, meaning it creates a heat-affected zone (HAZ) a small area around the cut where heat slightly alters the material. In most industrial applications, this has no impact on part performance or downstream assembly.

Water jet cutting, by contrast, is a cold-cutting process with no HAZ. However, it is typically slower and more expensive, especially for thick metals. For suppliers focused on throughput and cost control, plasma cutting is often the more practical choice.

Choosing the Right Process for Production Programs

From a supplier’s perspective, plasma cutting excels when speed, throughput, and scalability matter most. Many advanced fabrication shops operate both technologies, using plasma cutting for production efficiency and water jet cutting for specialized, heat-sensitive components.

Plasma Cutting Applications for Die Cast Metal Components

Plasma cutting is frequently used as a secondary operation for die cast metal parts. While die casting produces near-net-shape components, secondary trimming or feature modification is often required to meet final specifications.

Trimming and Modification of Die Cast Parts

Plasma cutting enables suppliers to remove excess material, add slots, or adjust features without complex tooling. This is particularly valuable during early production runs when designs are still being refined.

Supporting Production Consistency

For suppliers producing die cast components at scale, plasma cutting ensures consistency across batches. CNC-controlled plasma systems maintain dimensional accuracy while supporting high throughput, a key requirement for OEM supply chains.

Plasma Cutting in PPAP and Production Approval Workflows

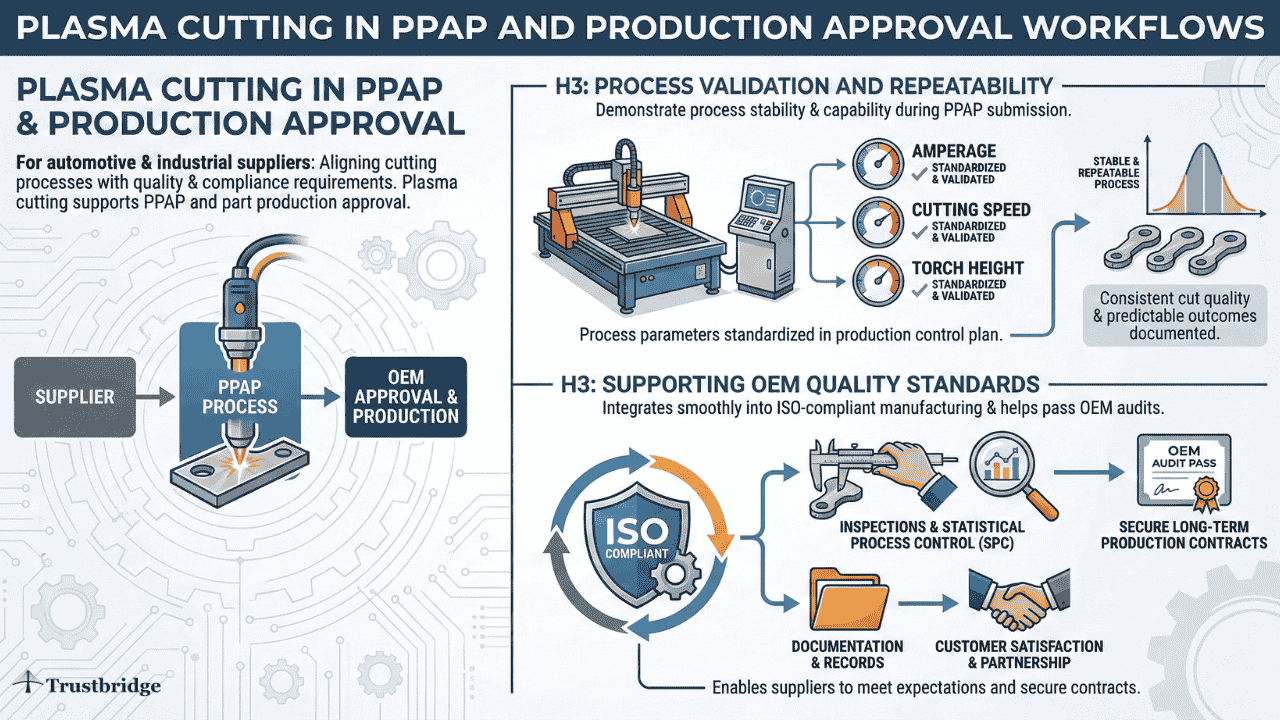

For automotive and industrial suppliers, cutting processes must align with formal quality and compliance requirements. Plasma cutting plays a role in meeting expectations under the PPAP process and the broader part production approval process.

Process Validation and Repeatability

During PPAP submission, suppliers must demonstrate that their manufacturing processes are stable, repeatable, and capable of producing parts within specification. Plasma cutting systems, when properly documented and controlled, support this requirement through consistent cut quality and predictable outcomes.

Process parameters such as amperage, cutting speed, and torch height can be standardized and validated as part of the production control plan.

Supporting OEM Quality Standards

Plasma cutting integrates smoothly into ISO-compliant manufacturing environments. When combined with inspections and statistical process control, it helps suppliers pass OEM audits and secure long-term production contracts.

Integration of Plasma Cutting in Modern Custom Manufacturing

As custom manufacturing becomes increasingly digital, plasma cutting systems are evolving alongside Industry 4.0 initiatives. Today’s systems integrate with CAD/CAM software, ERP platforms, and automated material handling.

Some advanced plasma systems now incorporate AI-based optimization, automatically adjusting cut parameters to improve edge quality, reduce scrap, and extend consumable life. These smart features help suppliers increase efficiency while reducing operational costs.

Trustbridge Tip: Plasma cutting adds speed and flexibility, but OEMs expect more than fast cuts. During PPAP approval, buyers look for documented, repeatable processes. Clearly defining plasma cutting parameters, inspection steps, and control plans shows that your operation is production-ready not just capable. Suppliers that validate plasma cutting as part of their PPAP process reduce approval delays and build long-term OEM trust. Learn what buyers expect in our blog: What Do OEMs Expect to See in a Strong PPAP Submission From Suppliers?

Key Considerations for Suppliers Investing in Plasma Cutting

Suppliers evaluating plasma cutting systems should consider production volume, material range, tolerance requirements, and downstream processes. While plasma cutting is versatile, optimal performance depends on selecting the right system for specific production goals.

Training, preventive maintenance, and clear process documentation remain essential for long-term consistency and customer satisfaction.

Suppliers planning to add plasma cutting capacity should request sample cuts or production quotes from qualified fabrication partners to validate cycle time, edge quality, and cost impact before committing to equipment or outsourcing decisions.

Conclusion: Why Plasma Cutting Remains Essential for Industrial Suppliers

Understanding what a plasma cutter is goes beyond knowing how it cuts metal. For industrial suppliers, plasma cutting represents speed, flexibility, and production readiness. Its role in custom manufacturing, compatibility with die cast metal, alignment with PPAP process requirements, and comparison with CNC machine water jet cutting make it a core capability in modern fabrication.

As OEMs demand faster turnaround times and tighter quality control, plasma cutting continues to be a reliable and scalable solution within the part production approval process.

Ready to take your production to the next level?

Start by evaluating whether plasma cutting can reduce your lead times, improve throughput, or lower part costs. Request a production quote, compare cutting technologies, and validate the process against OEM quality expectations before your next sourcing decision.

Partner with experienced manufacturing platforms that connect you with qualified buyers, validated production programs, and long-term supply opportunities. Build credibility, increase throughput, and future-proof your fabrication business today.

Frequently Asked Questions (FAQs)

1. What is a plasma cutter used for in industrial metal fabrication?

A plasma cutter is used to cut electrically conductive metals such as carbon steel, stainless steel, and aluminum. In industrial fabrication, suppliers rely on plasma cutting for fast profiling, trimming, and secondary operations where speed, scalability, and cost efficiency are critical for production programs.

2. How does plasma cutting compare to water jet cutting in production environments?

Plasma cutting is significantly faster and more cost-effective for thick metals and high-throughput production. While water jet cutting offers no heat-affected zone, it is slower and more expensive. Many suppliers use plasma cutting for structural and fabricated parts, reserving water jet cutting for heat-sensitive or precision-critical components.

3. Can plasma cutting be used for die cast metal components?

Yes. Plasma cutting is commonly used as a secondary operation for die cast metal parts. Suppliers use it to trim excess material, modify features, or adjust openings when tooling changes are not yet finalized, especially during early production or ramp-up phases.