Building Supply Chain Resilience Through Smarter Supplier Segmentation

In today's volatile global economy, supply chain resilience is no longer a buzzword; it is a critical necessity for business survival and growth. As organizations navigate a landscape defined by geopolitical shifts, inflationary pressures, and unpredictable consumer behavior, the traditional, one-size-fits-all approach to supplier management is proving to be a significant vulnerability. The modern imperative is to move beyond basic vendor lists to a more strategic, data-driven methodology: smarter supplier segmentation.

Global supply chains are undergoing a seismic shift. Rising costs, geopolitical tensions, climate risks, and rapid digitalization have forced businesses to rethink their supplier strategies. Traditional approaches that focused solely on cost optimization are no longer sufficient. Today, resilience, agility, and visibility define competitive advantage. This is not just about categorizing suppliers by volume or cost. It is about understanding the intricate web of relationships, risks, and opportunities within your supply network. By employing a nuanced segmentation model, businesses can proactively manage risks, optimize resource allocation, and build a supply chain that is not only robust but also agile and competitive. The insights gleaned from leading research and industry analysis show that companies that adopt this advanced approach gain a measurable advantage, from higher revenue growth to a more secure and predictable operational future.

Why Supplier Segmentation Matters Now More Than Ever

Supplier segmentation has evolved from a simple procurement task to a core strategic function. In the past, the focus was often on the Kraljic Matrix, which classifies suppliers based on profit impact and supply risk. While this framework remains a solid foundation, today’s landscape demands a more dynamic and multi-dimensional approach. Current industry trends highlight the need to incorporate factors like technological capability, innovation potential, sustainability, and alignment with a company's long-term strategic goals.

The global supply chain landscape is becoming more complex. Disruptions are no longer “black swan” events—they are expected. Whether it’s semiconductor shortages, raw material price volatility, or sudden trade restrictions, businesses need proactive measures. This shift is driven by the increasing complexity of global supply chains. A supplier who might be "non-critical" in terms of direct spend could be a "bottleneck" supplier if they are the only source for a unique, hard-to-find component. Conversely, a seemingly "strategic" supplier might lack the technological agility needed to adapt to rapid market changes. Therefore, a modern segmentation model must be fluid, continuously updated, and integrated with real-time data from various sources, including IoT devices, financial health indicators, and geopolitical monitoring tools. This ensures that the segmentation remains relevant and actionable in a rapidly changing environment. This sophisticated level of analysis enables businesses to move from a reactive to a proactive stance, addressing potential disruptions before they escalate into major crises. By actively monitoring these new dimensions, a business can unlock hidden value and foster collaborative relationships that lead to joint innovation and efficiency gains.

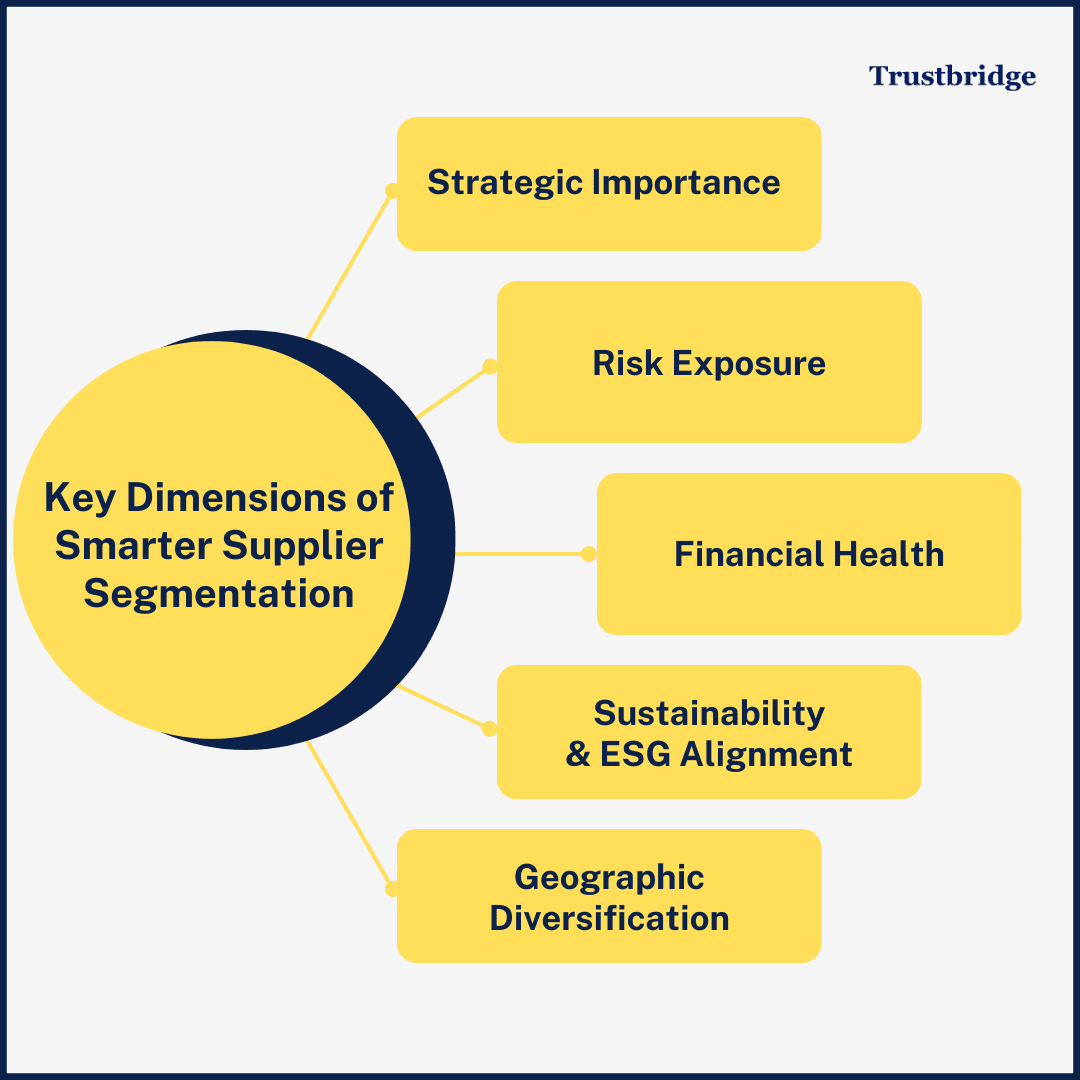

Key Dimensions of Smarter Supplier Segmentation

Effective segmentation goes beyond a single metric. Leading businesses today use a multi-dimensional framework that incorporates several key criteria to paint a complete picture of their supply network.

Strategic Importance: Does the supplier provide unique value, or are they a critical partner for innovation and long-term growth? This goes beyond cost to assess the relationship's strategic alignment and potential for co-creation.

Risk Exposure: What is the probability and potential impact of disruptions from this supplier? This includes operational risks like delivery failures and geopolitical risks related to sourcing regions.

Financial Health: Can the supplier withstand economic downturns and market volatility? Analyzing their financial stability and ability to avoid insolvency is crucial for ensuring continuity and avoiding surprises.

Sustainability & ESG Alignment: Do the supplier's environmental, social, and governance (ESG) commitments align with your company’s values and goals? This is a growing imperative driven by regulatory requirements and consumer demand for ethical practices.

Geographic Diversification: Can supply continuity be maintained across regions? This helps businesses mitigate risks associated with a single point of failure in a specific country or region.

Businesses increasingly integrate AI-driven risk analytics, sustainability scoring, and predictive modeling into these segmentation frameworks. This ensures procurement teams can respond dynamically to emerging threats while aligning with long-term corporate responsibility goals. This advanced approach transforms static data points into actionable insights, providing a holistic view that allows for more informed decision-making across the organization. By continuously evaluating these dimensions, companies can maintain a dynamic and accurate understanding of their supplier base, which is crucial for building a truly resilient supply chain in today's unpredictable world.

Trustbridge Tip: Looking for ways to improve your supplier relationships and boost profitability? Read our blog for actionable strategies.

Leveraging Data and Technology for Smarter Segmentation

The key to implementing smarter supplier segmentation lies in leveraging advanced data and technology. The advent of artificial intelligence (AI) and machine learning (ML) has revolutionized how procurement teams can analyze vast datasets to uncover hidden patterns and risks. Modern Supplier Relationship Management (SRM) platforms are no longer just repositories of information; they are analytical powerhouses that can automate the segmentation process, providing real-time, data-driven insights.

Big data and advanced analytics play a pivotal role, transforming raw information on everything from on-time delivery rates to financial health and ESG compliance into actionable intelligence. This granular visibility allows for a deeper understanding of your supply network, often extending beyond first-tier suppliers to sub-tier networks where many hidden vulnerabilities reside. Implementing digital twin technology can further enhance this, creating a virtual model of your supply chain to simulate disruptions and test mitigation strategies. By integrating these technologies, companies can move away from static, quarterly reviews to a continuous, predictive model of supplier management, ensuring a more resilient and agile supply chain. The ability to forecast and prepare for future shocks provides a significant competitive edge, turning potential threats into opportunities for strategic realignment. These tech-driven tools provide the intelligence needed to not just react, but to proactively shape a secure and efficient supply chain.

Tailored Strategies for Each Supplier Segment

Once suppliers are accurately segmented, the next critical step is to develop tailored management strategies for each group. A strategic supplier, for example, is not just a vendor; they are a partner. These relationships require a collaborative approach, with a focus on long-term value creation, joint product development, and shared risk management. On the other hand, a "leverage" supplier, where there are multiple alternatives, is an opportunity for cost optimization through competitive bidding and robust negotiation.

For "bottleneck" suppliers, the strategy must be centered on risk mitigation, such as developing alternative sourcing options or building up safety stock. For "non-critical" or "transactional" suppliers, the focus should be on automation and efficiency to minimize management effort and free up resources for more strategic activities. This customized approach ensures that resources—both human and financial—are allocated where they can deliver the greatest impact. It moves the organization from a uniform, and often inefficient, management style to one that is highly focused and effective, strengthening critical relationships while streamlining routine operations. This differentiated engagement model not only enhances operational efficiency but also builds stronger, more trusted relationships with your most vital partners, reinforcing the entire supply chain network against future shocks.

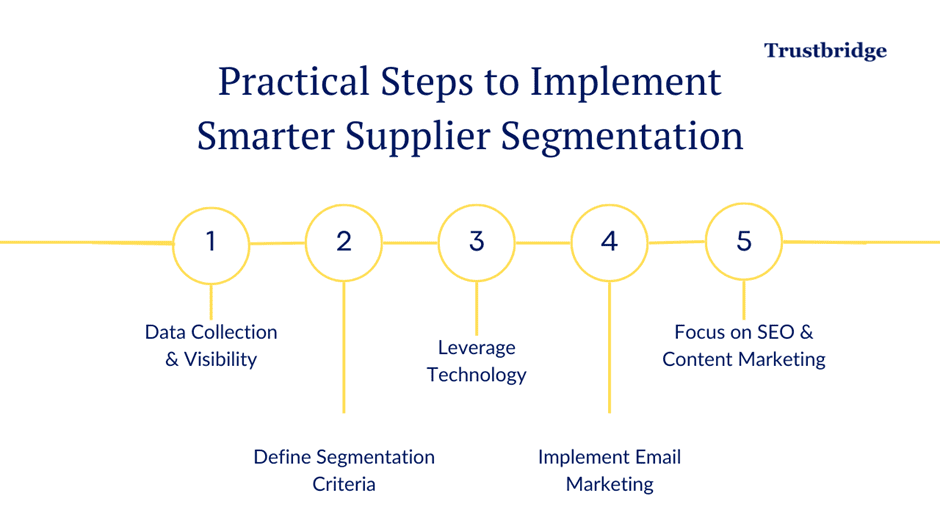

Practical Steps to Implement Smarter Supplier Segmentation

Data Collection & Visibility: Begin by mapping your entire supplier base, gathering comprehensive data on performance, risks, and spending. Visibility is the foundation of any effective segmentation model.

Define Segmentation Criteria: Clearly align your segmentation criteria with your overarching business goals, resilience needs, and sustainability targets. This ensures the model is relevant and impactful.

Leverage Technology: Adopt modern procurement platforms, AI-powered analytics, and dashboards to automate the process and gain real-time insights. Manual segmentation is simply too slow for today’s pace of change.

Collaborate with Stakeholders: Involve key departments like procurement, finance, risk management, and operations from the beginning. A holistic approach ensures buy-in and a more effective implementation.

Continuous Monitoring: Treat supplier segmentation as an evolving process, not a one-time project. Regularly review and update your segments based on new data, market trends, and internal strategy shifts.

Companies adopting continuous segmentation see long-term cost savings and reduced supply risks. Integrating external market signals—such as trade policy changes, climate risk models, and supplier bankruptcy alerts—ensures that segmentation evolves with global dynamics. This constant adaptation transforms the supply chain from a reactive cost center into a proactive, value-adding engine for the business. By following these steps, organizations can systematically build a more robust and responsive supply chain framework.

Conclusion: The Path to Enduring Resilience

Building supply chain resilience is an ongoing journey, not a one-time project. It requires a fundamental shift in mindset from risk management to strategic partnership. Smarter supplier segmentation, powered by data, technology, and a deep understanding of your business goals, is the definitive roadmap for this transformation. By moving beyond traditional, rigid frameworks and embracing a dynamic, multi-dimensional approach, organizations can build a supply chain that not only withstands disruption but thrives on it.

The investment in this strategic discipline pays dividends in the form of enhanced operational agility, reduced risk exposure, and a significant competitive advantage. In a world where the only constant is change, a resilient supply chain is the ultimate asset, ensuring continuity, security, and long-term success. It positions a business to navigate future uncertainties with confidence, turning what others see as threats into a catalyst for innovation and market leadership. The future belongs to those who see their suppliers not just as vendors but as vital co-creators of value and resilience.

📩If you're ready to translate the principles discussed here into tangible results for your next project, Trustbridge's team of supply chain and manufacturing specialists is here to help. Whatever product or part you are looking to design or manufacture, Trustbridge is capable of augmenting your existing supply chain with its in-house design services and global network of manufacturers. Contact us today to learn how we can partner with you to engineer a more sustainable future.