10 Ways Buyers Can Reduce Supply Chain Disruptions

In today’s volatile global economy, buyers who treat all suppliers the same often pay the price with higher costs, delays, and customer dissatisfaction. Procurement teams, product developers, and supply chain managers are under constant pressure to ensure reliability, but a one-size-fits-all approach is a recipe for disaster.

It's a frustrating cycle: a critical supplier faces a disruption, and because you've managed them the same way as everyone else, you're left scrambling. This can lead to production halts, panicked calls from customers, and a significant hit to your bottom line. The feeling of being constantly on the back foot and reacting to crises instead of preventing them is exhausting.

The key is to stop this cycle by proactively planning, applying analytics, and managing suppliers strategically rather than uniformly. This guide explores 10 proven ways buyers can reduce supply chain disruptions while building stronger, more reliable supplier relationships.

What Is a Supply Chain Disruption?

Trustbridge Tip: Learn how AI is revolutionizing procurement, empowering buyers to shift from administrative tasks to strategic decisions that create more resilient, future-ready supply chains. Read the full blog post here.

What Causes Supply Chain Disruptions?

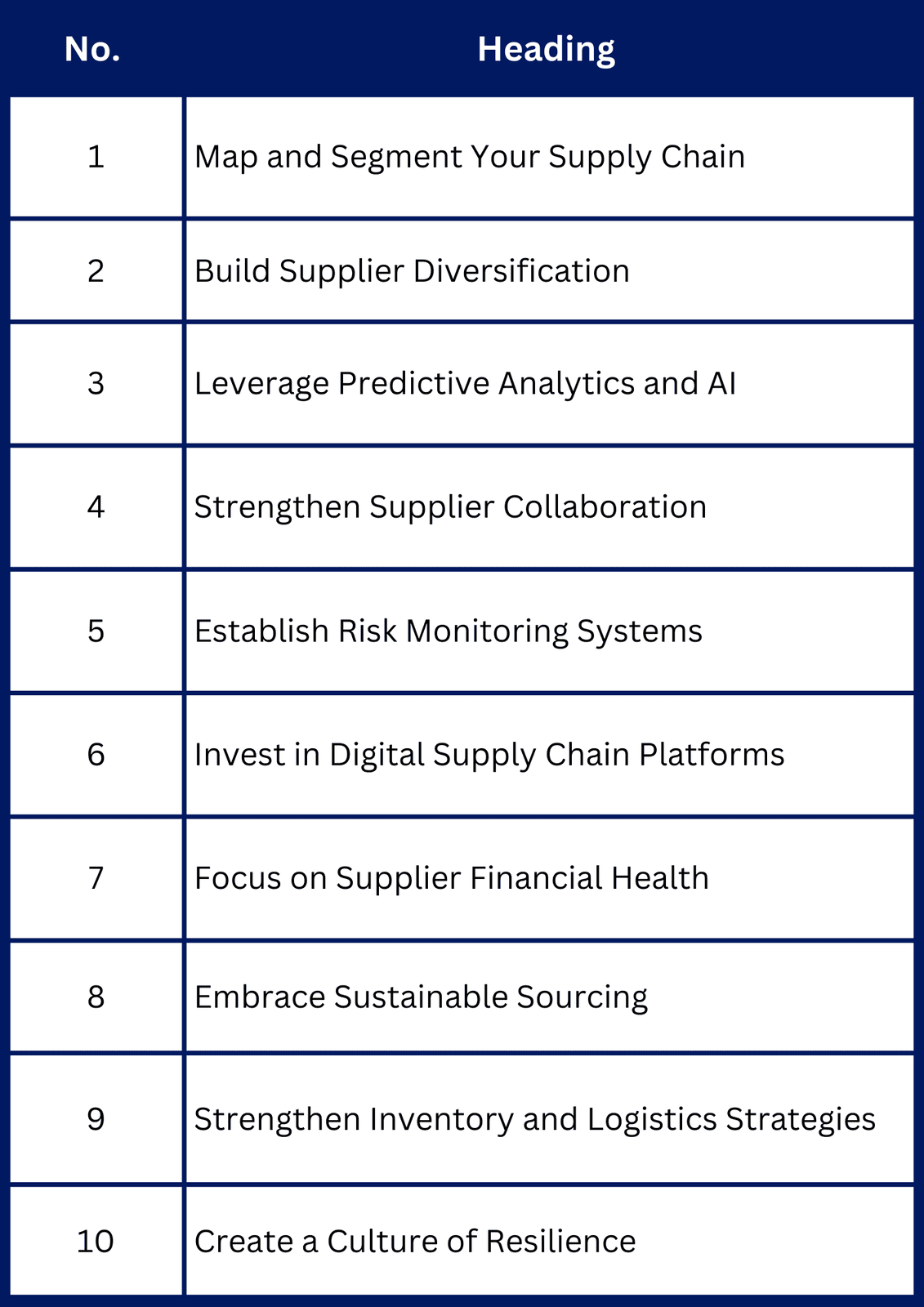

How to Reduce Supply Chain Disruptions

Read this carefully, here are ten foundational strategies to build a resilient, future-ready supply chain and buyers:

Now let’s break each one down and understand how they drive long-term agility and risk mitigation.

1. Map and Segment Your Supply Chain

For buyers, visibility is the foundation of resilience. Mapping the end-to-end supply chain, including Tier 2 and Tier 3 suppliers, gives procurement teams clarity on where risks lie. Segmenting suppliers by importance and risk helps allocate resources effectively. Strategic suppliers require deeper collaboration, while transactional ones can be managed with standard processes.

Buyers who apply segmentation gain insight into single points of failure and dependency risks. This allows them to invest in backup options for high-risk suppliers while keeping transactional categories cost-efficient. Mapping and segmentation empower buyers to make smarter sourcing decisions, ensuring fewer disruptions and more reliable outcomes.

2. Build Supplier Diversification

Relying on one supplier or one region puts buyers in a vulnerable position. Diversifying suppliers across geographies reduces the risk of disruptions caused by regional crises or logistics breakdowns. Many buyers now apply dual-sourcing strategies, nearshoring, or reshoring to spread risk.

Beyond risk reduction, diversification provides buyers with stronger negotiating leverage, reducing price fluctuations. A balanced supplier portfolio with a mix of local, nearshore, and offshore partners, creates flexibility when demand shifts. Buyers who prioritize diversification are better equipped to maintain continuity and meet customer expectations during crises.

3. Leverage Predictive Analytics and AI

For buyers, anticipating problems before they arise is crucial. Predictive analytics and AI tools enable procurement teams to forecast demand changes, identify supplier delays, and evaluate geopolitical risks. Buyers can set up early warning systems that flag issues before they escalate.

AI also supports scenario planning, allowing buyers to model outcomes like port closures or raw material shortages. This gives decision-makers flexibility to adjust orders, shift suppliers, or redirect logistics in real time. By adopting predictive tools, buyers move from reacting to disruptions to proactively minimizing their impact.

4. Strengthen Supplier Collaboration

Buyers who treat suppliers as partners — not just vendors — build stronger resilience. Open communication, shared forecasting, and joint planning encourage suppliers to prioritize your business when disruptions occur. Collaborative initiatives also help align long-term goals and drive innovation.

Strong relationships allow buyers to gain early insights into supplier challenges, giving them time to adapt. Suppliers who feel valued often offer preferential treatment during shortages. For procurement leaders, investing in collaboration not only strengthens resilience but also builds long-term trust and loyalty.

5. Establish Risk Monitoring Systems

Buyers must monitor risks continuously, not just during a crisis. Risk monitoring tools can track real-time events like weather changes, port congestion, or raw material shortages. By integrating dashboards into procurement workflows, buyers can respond quickly to disruptions.

Advanced systems powered by IoT and AI provide instant alerts and suggest response options, such as rerouting orders or adjusting inventory. This proactive monitoring minimizes lag time between a disruption and buyer action, preventing small issues from becoming major breakdowns. Buyers with risk monitoring systems in place are consistently more resilient.

Trustbridge Tip: Looking for a cutting-edge way to combat supply chain disruptions? Explore how additive manufacturing can transform your strategy by enabling localized production and on-demand parts. Download our ultimate guide to learn more.

6. Invest in Digital Supply Chain Platforms

Buyers who embrace digital supply chain platforms gain transparency, speed, and control. Cloud-based platforms centralize data on inventory, shipments, and supplier performance, enabling procurement teams to detect inefficiencies and act immediately.

Integrating these platforms with ERP and CRM systems further enhances visibility and collaboration across the organization. Buyers benefit from automated processes, faster communication with suppliers, and real-time tracking. In fast-changing markets, these digital tools give buyers the agility needed to handle disruptions effectively.

7. Focus on Supplier Financial Health

Buyers cannot afford to ignore the financial health of their suppliers. A supplier’s bankruptcy or cash flow crisis can halt production overnight. By regularly reviewing financial stability, buyers can anticipate risks and prepare alternatives.

Procurement teams can use credit scoring tools and monitor real-time financial indicators to spot early warning signs. In some cases, buyers may offer early payments to critical suppliers to maintain stability. Ensuring suppliers are financially healthy protects buyers from sudden breakdowns and secures continuity.

8. Embrace Sustainable Sourcing

For buyers, sustainability isn’t just about compliance — it’s about resilience. ESG-focused procurement reduces risks tied to regulations, resource scarcity, and reputational damage. Ethical sourcing strengthens supplier loyalty and lowers the chance of unexpected regulatory or environmental disruptions.

Sustainable practices also appeal to end customers, giving buyers an additional competitive advantage. By embedding sustainability into supplier selection, buyers secure long-term supply while building trust with both stakeholders and customers. Procurement teams that prioritize ESG also open the door to innovation and cost savings.

9. Strengthen Inventory and Logistics Strategies

Buyers balancing lean inventory models with resilience must carefully manage logistics. While just-in-time (JIT) reduces costs, it increases exposure to shortages. Maintaining safety stock for critical materials ensures continuity when disruptions strike.

Procurement leaders should also develop multiple logistics partnerships to handle transportation delays or port blockages. Regional warehousing adds flexibility for faster delivery. By combining efficiency with resilience, buyers can protect service levels while managing costs effectively.

10. Create a Culture of Resilience

Ultimately, buyers benefit when resilience is embedded in organizational culture. Procurement teams trained in scenario planning and agile decision-making respond faster to disruptions. Cross-functional collaboration between procurement, operations, and finance ensures a unified response.

Leadership must champion resilience by investing in training, digital tools, and continuous improvement initiatives. Buyers who adopt resilience as a long-term philosophy rather than a one-off project, gain a competitive advantage in a volatile global market.

Final Thoughts

For buyers, the cost of treating all suppliers is the same: delays, rising expenses, and missed opportunities. By mapping and segmenting your supply chain, diversifying suppliers, embracing predictive analytics, and fostering collaboration, you can transform disruption from a constant threat into a managed risk. The key is to shift from reactive fixes to proactive resilience, supported by digital platforms, financial monitoring, sustainability practices, and agile procurement.

Organizations that embed resilience into their culture don’t just survive disruptions; they gain a competitive edge, maintain customer trust, and secure long-term growth. The message for buyers is simple: resilience is not optional; it is the foundation of a future-ready supply chain. As markets continue to shift rapidly, buyers who act now to strengthen resilience will position themselves as leaders in their industry. Investing in the right strategies today ensures that tomorrow’s challenges become opportunities rather than setbacks.

Ready to move your procurement from spreadsheets to strategy? AI is no longer optional — it’s the backbone of modern buying. Empower your procurement team with intelligent sourcing, real-time spend visibility, and smarter decision-making. Visit Trustbridge.pro to explore buyer resources, case studies, and solutions designed to help procurement professionals lead with confidence.