PPAP Approval Process: What OEM Suppliers Must Get Right Before Production

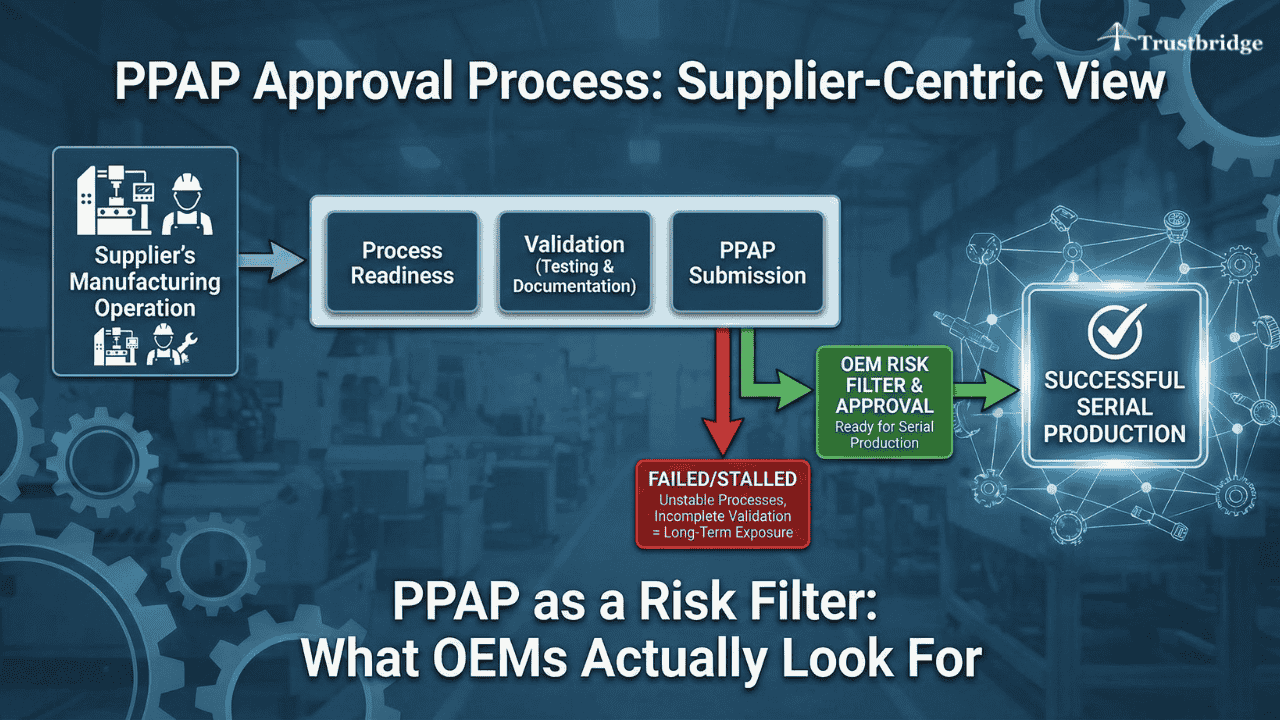

For OEM suppliers, the PPAP approval process is more than a customer requirement—it is a direct measure of whether your manufacturing operation is truly ready for production. While PPAP is often discussed from the buyer’s side, suppliers experience the real impact when PPAP submissions fail, stall, or trigger escalations.

Production failures rarely begin on the shop floor. They are often locked in weeks earlier during PPAP submission, when unstable processes or incomplete validation are passed forward as “approved.” OEMs increasingly rely on PPAP approval as a risk filter to decide which suppliers are capable of serial production and which introduce long-term exposure.

This guide explains the PPAP approval process from a supplier-centric viewpoint, focusing on Production Part Approval Process requirements, production validation, and what OEMs actually look for when approving suppliers.

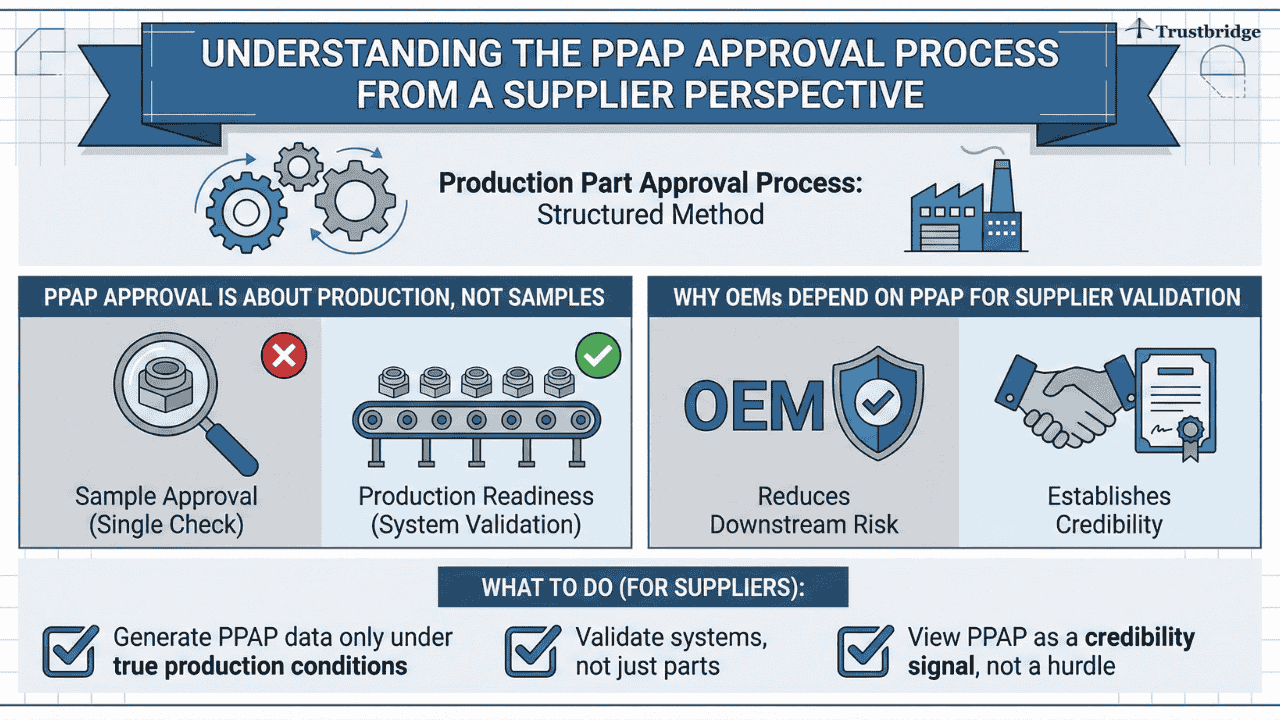

Understanding the PPAP Approval Process from a Supplier Perspective

The PPAP approval process, formally known as the Production Part Approval Process, is a structured method OEMs use to verify that a supplier can repeatedly manufacture parts that meet all engineering and quality requirements under real production conditions.

For suppliers, PPAP is not a document set. It is evidence that the PPAP process has validated tooling, materials, people, machines, and controls as a complete system.

PPAP Approval Is About Production, Not Samples

One of the most common supplier misconceptions is equating sample approval with PPAP approval. A part that passes dimensional inspection once does not guarantee production readiness. The PPAP process requires suppliers to demonstrate that their manufacturing system can perform reliably across time, volume, and variation.

OEMs evaluate PPAP submissions to confirm that production intent tooling, production materials, and production processes are in place. If a supplier submits data generated under non-production conditions, PPAP approval may be delayed or rejected.

Why OEMs Depend on PPAP for Supplier Validation

From the OEM perspective, PPAP approval reduces downstream risk. For suppliers, it is an opportunity to establish credibility. A clean, complete PPAP signals that the supplier understands process control, documentation discipline, and change management. Weak PPAP submissions often raise concerns about broader operational maturity.

What to Do (For Suppliers):

- Generate PPAP data only under true production conditions

- Validate systems, not just parts

- View PPAP as a credibility signal, not a hurdle

The PPAP Process and Its Role in Production Readiness

The PPAP process exists to validate that a manufacturing system is capable, documented, and under control before volume production begins. Suppliers who approach PPAP strategically reduce customer friction and avoid repeated resubmissions.

Process Validation Within the PPAP Process

At the core of the PPAP process is process validation. OEMs want evidence that suppliers have defined workflows, controlled variables, and verified process capability. This includes confirmation that machines, tooling, fixtures, and inspection methods operate consistently under production conditions.

Suppliers that fail to validate their process often discover issues only after production ramps up, when corrections are more costly and disruptive.

Documentation as Evidence, Not Bureaucracy

PPAP documentation exists to tell the story of how a part is made and controlled. When suppliers treat documentation as an afterthought, inconsistencies emerge. OEM reviewers quickly recognize when control plans, process flows, and inspection records are misaligned.

Strong PPAP submissions show logical continuity from process design to inspection strategy, reinforcing confidence in supplier execution.

What to Do (For Suppliers):

- Validate process capability before submitting PPAP

- Ensure documentation reflects actual shop-floor practices

- Check alignment across flowcharts, control plans, and inspections

PPAP Production Expectations Suppliers Must Meet

PPAP production requirements go beyond engineering compliance. OEMs evaluate whether suppliers can sustain quality at scale, manage variation, and respond predictably to change.

PPAP Production vs Prototype Manufacturing

Prototype manufacturing allows flexibility. PPAP production does not. OEMs expect suppliers to use production-intent equipment, tooling, and materials when generating PPAP data. Any deviation introduces uncertainty.

Suppliers that rely on temporary fixtures, substitute materials, or non-standard inspection methods during PPAP production often face rejection or conditional approval.

Process Capability and Stability in PPAP Production

OEMs assess whether suppliers can hold tolerances consistently over time. Demonstrating process stability is essential for PPAP production approval. If variation is not understood or controlled, OEMs may delay approval until corrective actions are validated.

For suppliers, this reinforces the importance of disciplined process setup and repeatable execution before submission.

What to Do:

- Use only production-intent setups for PPAP data

- Demonstrate stability, not short-term performance

- Resolve variation before submission—not after rejection

The Production Part Approval Process as a Risk Filter

The production part approval process acts as a gate between development and serial production. For suppliers, it is one of the clearest indicators of how OEMs assess risk.

How OEMs Use the Production Part Approval Process

OEMs rely on the production part approval process to identify weak points in supplier operations. Missing data, unclear traceability, or inconsistent records often suggest deeper issues in manufacturing discipline.

Suppliers that consistently pass PPAP demonstrate reliability, which strengthens long-term sourcing relationships.

Supplier Accountability in the Approval Process

Once PPAP approval is granted, suppliers are expected to maintain the validated process. Unauthorized changes to materials, tooling, or methods undermine the production part approval process and often lead to customer escalations.

Suppliers who understand this responsibility treat PPAP approval as a commitment, not a milestone.

What to Do:

- Maintain strict change control after PPAP approval

- Preserve traceability and documentation discipline

- Treat PPAP approval as an ongoing obligation

Trustbridge Tip: Passing the PPAP approval process isn’t just about documentation — it’s about proving that every manufacturing detail is controlled at production scale. Operations like counterboring directly affect assembly quality, fastener fit, and torque consistency, which OEMs closely evaluate during PPAP reviews. Inconsistent counterbore depth, surface finish, or tool wear can trigger dimensional failures, assembly issues, and delayed approvals, even when parts appear compliant on paper. To understand how counterbore operations influence supplier reliability and downstream assembly performance, read our blog: How Do Counterbore Operations Impact Assembly Quality and Supplier Reliability?

Common Supplier Mistakes During the PPAP Approval Process

Even experienced suppliers encounter issues during PPAP approval. Many failures stem from misalignment rather than technical inability.

Incomplete or Misaligned PPAP Submissions

Suppliers often submit PPAPs with mismatched documentation. When process flows, control plans, and inspection results do not align, OEMs lose confidence in the submission.

Rushing PPAP to Meet Delivery Pressure

Schedule pressure leads some suppliers to rush PPAP submissions before processes are fully stabilized. This short-term approach often results in rejection, rework, and delayed approval, ultimately extending timelines rather than shortening them.

Treating PPAP as a One-Time Event

PPAP approval does not eliminate future responsibility. Suppliers who fail to maintain process discipline after approval risk nonconformances and customer corrective actions.

What to Do:

- Audit internal alignment before submission

- Resist delivery pressure that compromises validation

- Plan for PPAP as a lifecycle process

How Suppliers Can Strengthen Their PPAP Approval Process

Suppliers that consistently earn PPAP approval approach the process with preparation and structure.

Aligning Internal Teams Before Submission

Successful PPAP approval begins with internal alignment. Engineering, quality, and production teams must operate from the same process assumptions. When internal alignment is weak, inconsistencies appear in documentation and data.

Using the PPAP Process to Demonstrate Maturity

Suppliers who view the PPAP process as a strategic opportunity, rather than an obligation, position themselves as reliable partners. Clear documentation, stable data, and proactive communication reinforce trust.

Preparing for Ongoing Production After Approval

PPAP approval is the starting point for production, not the finish line. Suppliers should ensure that controls, training, and monitoring systems remain active throughout production.

What to Do:

- Align teams early and document shared assumptions

- Use PPAP to signal operational maturity

- Keep controls active beyond approval

Why the PPAP Approval Process Shapes Long-Term Supplier Success

OEMs remember which suppliers prevent problems and which create them. The PPAP approval process often defines that reputation early.

Suppliers who master PPAP approval gain more than customer acceptance. They gain preferred status, repeat business, and greater resilience during sourcing shifts. Those who treat PPAP casually often face audits, containment actions, and reduced sourcing confidence.

What to Do:

- Use PPAP to build a long-term supplier reputation

- Aim for consistency, not just compliance

- Position PPAP success as a competitive advantage

Conclusion:

The PPAP approval process is one of the most powerful tools OEMs use to assess supplier readiness. For suppliers, it is an opportunity to prove that production systems are stable, controlled, and scalable.

By understanding the PPAP process, validating PPAP production conditions, and respecting the production part approval process as a risk-control mechanism, suppliers position themselves as dependable manufacturing partners.

Suppliers that approach PPAP with discipline prevent problems others are forced to react to. In competitive OEM supply chains, that difference defines who wins long-term production and who struggles to keep it.

Looking for a reliable CNC supplier? Contact us today to discuss your machining needs.

Frequently Asked Questions (FAQs)

1. What is the PPAP approval process and why do OEMs require it?

The PPAP approval process (Production Part Approval Process) is used by OEMs to verify that a supplier can consistently produce parts that meet all engineering and quality requirements under real production conditions. OEMs rely on PPAP to reduce supply risk, prevent production failures, and ensure suppliers are ready for serial manufacturing.

2. Is PPAP approval the same as sample or prototype approval?

No. Sample or prototype approval only proves that a part can meet specifications once. PPAP approval confirms that the supplier’s entire production system—including tooling, materials, processes, inspections, and controls—is stable and repeatable at production scale.

3. What are the most common reasons PPAP submissions get rejected?

PPAP submissions are commonly rejected due to misaligned documentation, non-production-intent data, unstable process capability, or unclear change control. When process flows, control plans, and inspection results do not tell a consistent production story, OEM confidence drops quickly.