How Coordinate Measuring Machines (CMMs) Improve Inspection Accuracy for Machined Parts

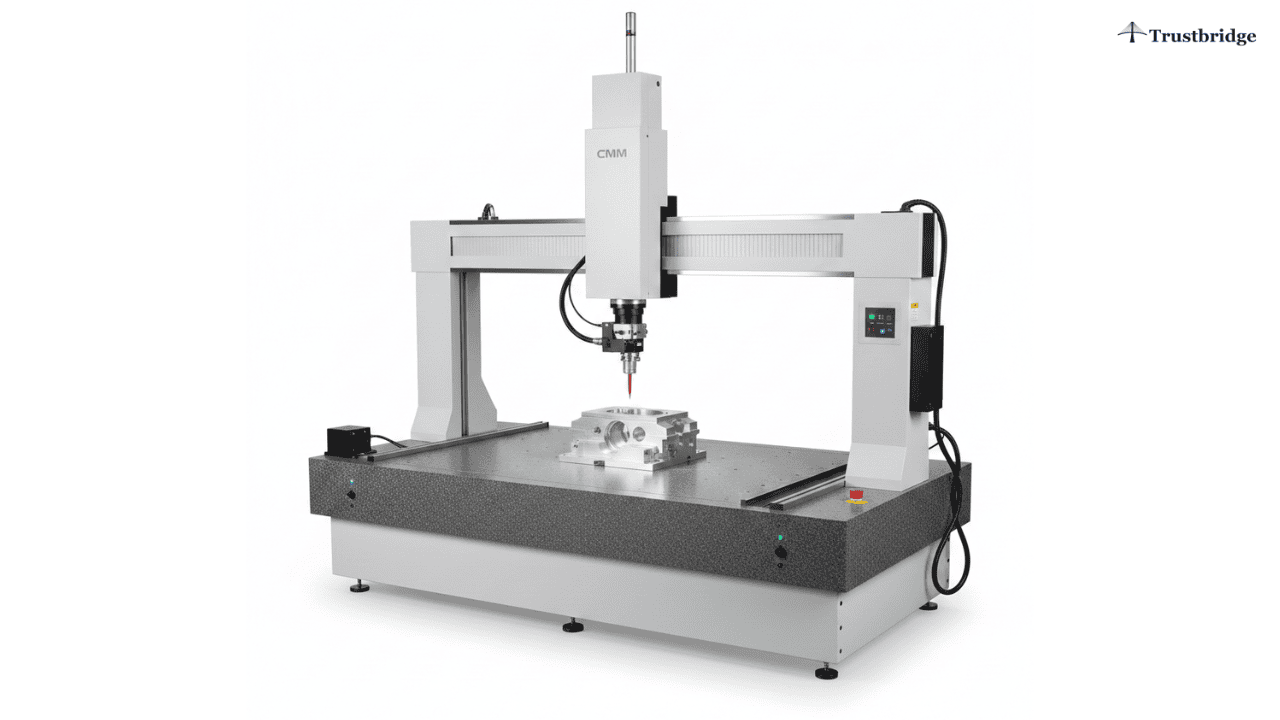

In today’s competitive manufacturing environment, precise measurement is essential. A Coordinate Measuring Machine (CMM) acts like a highly accurate digital ruler. It touches specific points on a part, records the exact location, and checks whether the part matches the original CAD design. With a CMM, manufacturers can detect small deviations early. This reduces scrap, lowers rework, and strengthens customer trust in a supplier’s machining and quality processes.

Why Use a Coordinate Measuring Machine for Machined Parts?

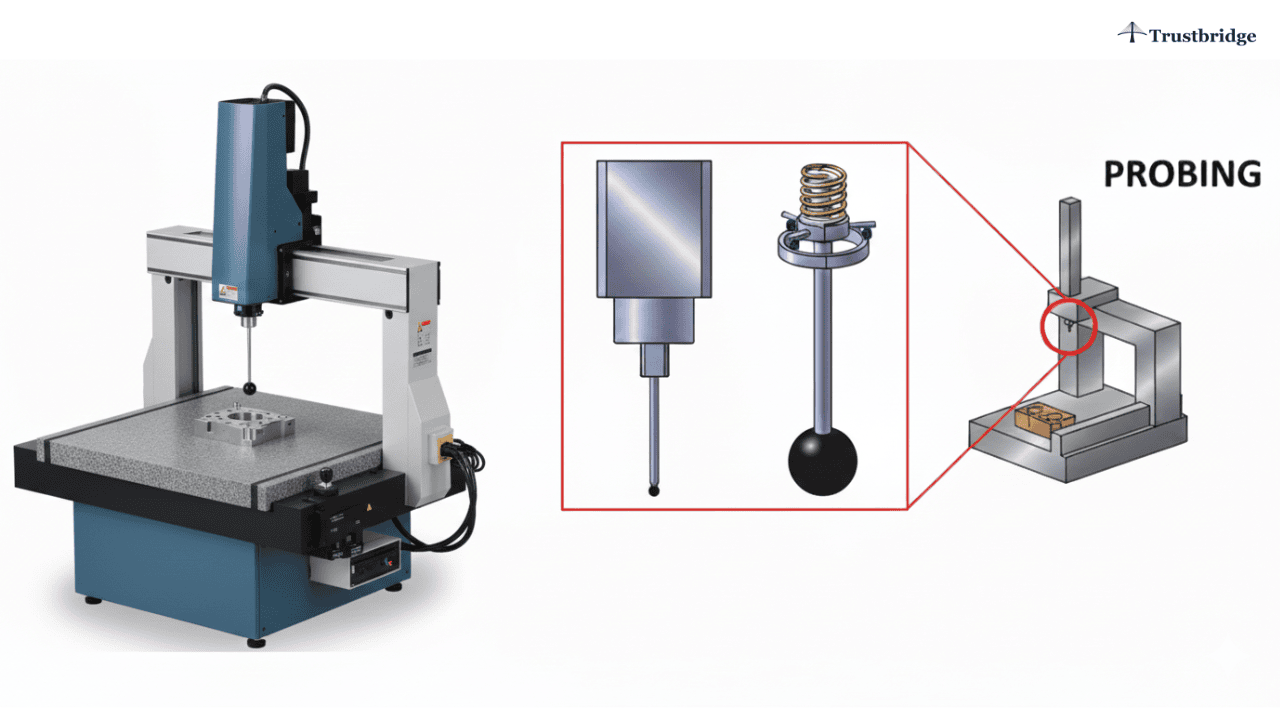

A CMM helps manufacturers verify whether a part meets its design specifications accurately. Unlike handheld tools such as calipers or micrometers, a CMM uses a probe that moves in three axes, X, Y, and Z, to capture precise measurements and compare them to the design model. According to Lead Metrology, this reduces human error and improves both accuracy and repeatability.

This level of precision matters most in industries where parts must fit together perfectly, such as aerospace and medical devices. Even tiny variations can affect performance. A CMM provides objective proof of accuracy, giving manufacturers confidence that their parts are built to the correct dimensions.

How CMM Helps CNC Machining Services Become More Reliable

CNC machining centers produce accurate parts, but no machining process is perfect. A CMM verifies critical dimensions as soon as a part is removed from the machine. Instead of assuming a CNC program is correct, operators can measure and confirm, catching issues before they spread through an entire batch.

According to Number Analytics, using a CMM inside the machining workflow allows teams to automate inspections, identify deviations early, and reduce material waste. Customers benefit because they receive parts that are “right the first time,” leading to fewer returns, fewer adjustments, and faster delivery cycles. Over time, this makes a CNC machining supplier more dependable and consistent.

Reducing Risk Through Supplier Certifications Like AS9100

High-precision industries, especially aerospace, often require suppliers to hold AS9100 certification. This standard shows that a shop follows strict quality requirements. A CMM helps support this by producing reliable, traceable inspection data that auditors can verify.

Choosing a supplier with AS9100 or ISO 9001 reduces customer risk. These certifications require shops to demonstrate how they inspect parts, how they calibrate their equipment, and how they maintain measuring systems. A CMM makes this easier by capturing micron-level measurements, logging every step of an inspection, and generating repeatable reports.

In simple words, AS9100 defines the quality rules, and a CMM helps prove that the rules are being followed on the shop floor.

Using AI and Smart Inspection Planning with CMM

Modern inspection systems now use AI to make CMM routines faster and smarter. Research on Industry 4.0 inspection planning shows that AI tools can optimize probe paths, cut measurement time, and reduce manual setup. When terms like “genetic algorithms” appear in research, they simply refer to software methods that help the CMM choose the most efficient way to measure a part.

By applying AI in manufacturing, companies reduce inspection delays and improve consistency. This helps create a more automated and predictable quality control process.

Common Challenges with CMM and How to Overcome Them

Using a CMM requires careful control. Temperature changes, machine vibration, and probe calibration can all affect measurement accuracy. These factors create “measurement uncertainty,” a term that describes how much real-world conditions can influence a reading.

Manufacturers address these challenges through best practices:

- They perform regular calibration to keep the CMM accurate.

- They train staff to understand probing methods, interpret results correctly, and identify potential errors.

They schedule inspections efficiently to avoid creating bottlenecks. According to Quality Magazine, minimizing unnecessary probe changes can help save significant time during inspection.

The Future of CMM in Digital Manufacturing

CMMs are becoming more connected, automated, and intelligent. In a smart factory environment, CMMs communicate directly with machining centers and feed real-time data into digital systems. This allows machines to adjust automatically when measurements show a potential issue.

Recent academic research describes advanced “CMM-based inspection planning systems” that use AI and optimization algorithms to reduce inspection time and improve accuracy. As factories continue adopting digital manufacturing workflows, CMMs will remain a key tool that links measurement, machining, and automation.

Trustbridge Tip: A CMM helps you prove accuracy, reduce scrap, and deliver reliable parts, but buyers also judge suppliers long before the first part is made. A fast, complete, and well-structured RFQ response shows that your shop is organized, quality-focused, and capable of meeting tight tolerances. Including inspection details, sample reports, or capability notes in your quote can immediately set you apart from competitors. To strengthen how your shop presents itself during the quoting stage and improve win rates, read our guide on the best ways CNC machining suppliers can boost their RFQ response process: What Are the Best Ways for CNC Machining Suppliers to Boost RFQ Response?

Conclusion

Visit Trustbridge.pro to explore resources, case studies, and solutions designed to help suppliers make smarter decisions.

Frequently Asked Questions (FAQs)

1. What does a CMM actually do in CNC machining?

A Coordinate Measuring Machine (CMM) measures key dimensions on a finished part and compares them to the CAD model. It helps confirm accuracy, catch deviations early, and reduce scrap or rework.2. How does a CMM make CNC machining services more reliable?

By checking critical dimensions right after machining, a CMM detects problems early—before a full batch is completed. This prevents errors, reduces waste, and ensures parts are “right the first time.”

3. Do CMMs help with certifications like AS9100 or ISO 9001?

Yes. Certifications require documented inspection, calibration, and traceability. A CMM generates digital inspection reports that auditors can easily verify, helping shops meet aerospace-level quality requirements.

4. What can affect CMM accuracy?

Temperature changes, vibration, poor calibration, and improper probing techniques can all introduce measurement uncertainty. Regular maintenance and proper training help prevent these issues.