Counterbore Operations: How Suppliers Can Improve Precision in Machined Parts

For CNC machining services suppliers competing on precision rather than price, execution details are a direct measure of credibility. Buyers may never step onto your shop floor, but they quickly notice when fasteners fail to seat properly, assemblies misalign, or tolerance stacks create downstream issues. In many of these cases, the root cause is not complex geometry or material variation, but inconsistent counterbore execution.

Counterbore operations play a critical role in how machined parts function, assemble, and perform in real-world applications. For suppliers positioning themselves as a precision machining supplier or tight-tolerance machining supplier, counterbore quality often becomes a deciding factor in repeat orders, sourcing confidence, and long-term customer relationships. This blog explains how suppliers can strengthen counterbore accuracy, reduce variability, and align this seemingly simple operation with modern supplier selection criteria.

Why Counterbore Accuracy Matters for CNC Suppliers

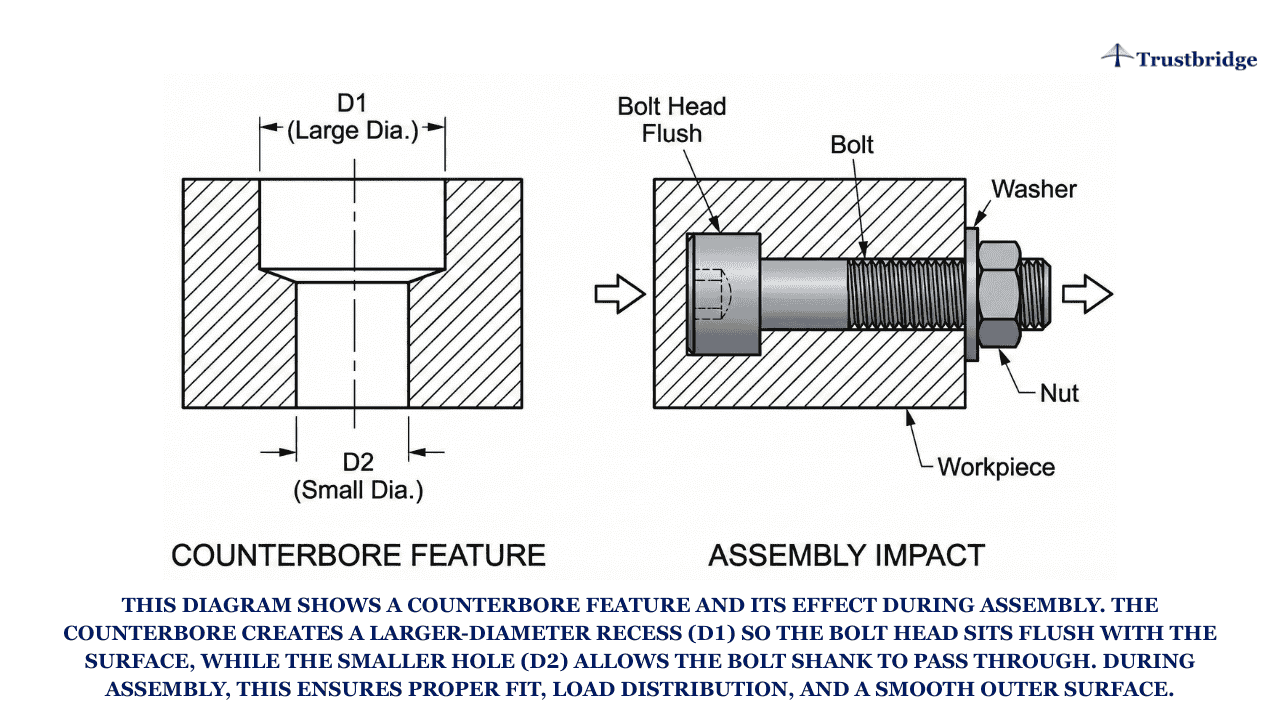

A counterbore is more than a flat-bottomed recess for a bolt head. From a supplier’s perspective, it directly affects part fit, assembly efficiency, and functional reliability. A counterbore that is only slightly too shallow may pass visual inspection, yet cause fasteners to bottom out before proper clamping leading to uneven load distribution during assembly or in service.

Manufacturers increasingly expect their CNC machining services partners to deliver components that assemble cleanly without additional adjustment or rework. Suppliers who consistently deliver accurate counterbores reduce friction on the assembly line, strengthen supplier credibility, and improve their chances of repeat business. In competitive sourcing environments, this reliability often separates serious suppliers from shops competing primarily on price.

Counterbore Operations as a Precision Indicator

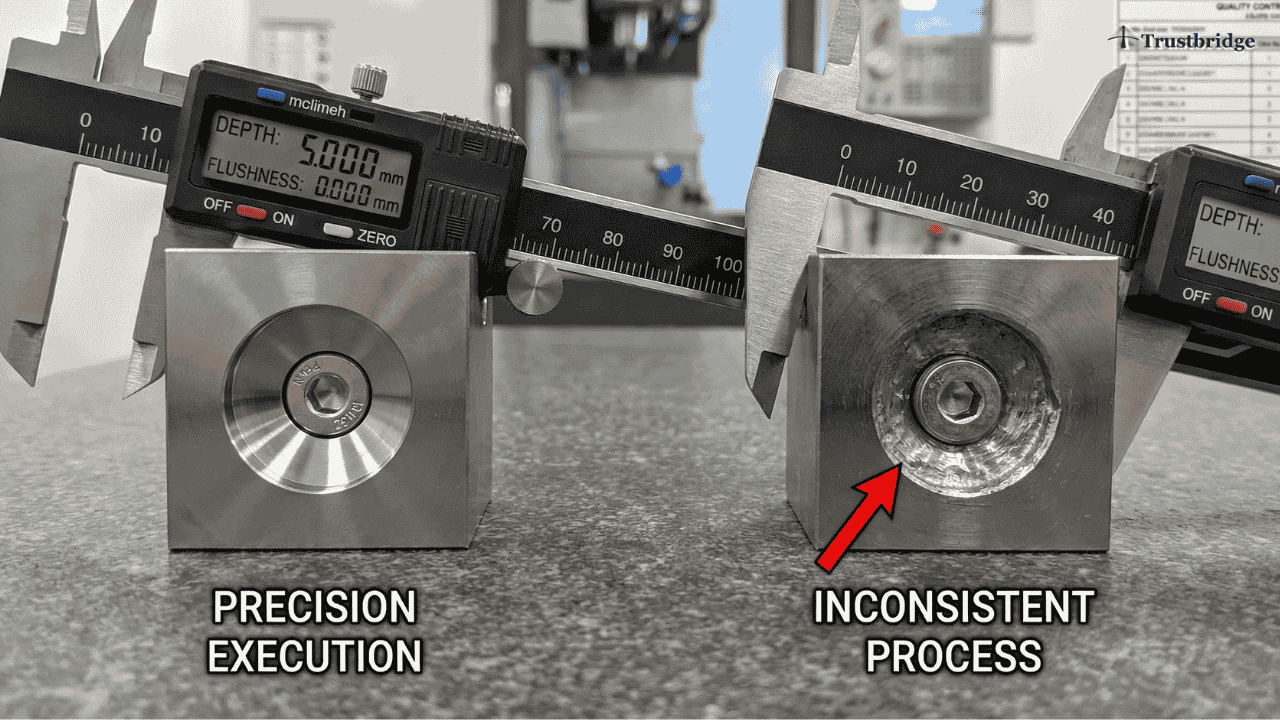

Buyers evaluating machining suppliers often look beyond headline tolerances and focus on execution consistency. Counterbores are one of the easiest features for them to assess. A fastener that sits flush, square, and repeatable across multiple parts signals strong process control and machining discipline.

For a tight-tolerance machining supplier, counterbore precision reflects how effectively tool wear is managed, offsets are controlled, and setups are validated. Suppliers who treat counterbores as secondary or “non-critical” operations frequently encounter depth variation and inconsistent surface finish, undermining otherwise high-quality work. Treating counterbore operations with the same rigor as critical bores or pockets elevates overall part quality and strengthens buyer perception.

Programming Strategies That Improve Counterbore Consistency

Counterbore accuracy begins at the programming stage. Tool selection, entry strategy, spindle speed, feed rates, and finishing passes all influence bottom flatness and wall quality. Suppliers with mature CNC machine and programming practices avoid aggressive plunging and instead use controlled entry moves and verified toolpaths to minimize deflection and chatter.

Depth control is especially critical. Even small Z-axis inconsistencies can cause fasteners to sit proud or sink below specification. Skilled programmers account for tool wear, material behavior, and machine response, often tracking tool life specifically for counterbore tools. This attention to detail is a clear indicator of suppliers capable of delivering consistent quality across materials, geometries, and batch sizes.

Machine Capability and Its Impact on Counterbore Precision

The ability to hold tight counterbore tolerances depends heavily on machine condition and capability. Spindle runout, axis backlash, thermal stability, and toolholder quality all directly influence counterbore accuracy. Suppliers who invest in routine calibration and machine health monitoring experience far fewer issues related to inconsistent depth, concentricity, or bottom flatness.

In small batch manufacturing, machine capability becomes even more critical. With fewer parts to absorb variation, any setup error or machine deviation is immediately visible. Suppliers who understand their machines deeply can adjust feeds, speeds, and cutting strategies to maintain counterbore consistency even in short-run and prototype production.

Inspection and Verification: Protecting Supplier Credibility

Although counterbores appear simple, verifying them requires discipline. Depth measurement, perpendicularity checks, and surface condition inspection are essential to ensuring functional performance. Suppliers who rely only on visual checks often miss subtle issues that later surface as assembly problems or customer complaints.

Advanced suppliers integrate probing cycles or structured post-process inspection to validate counterbore features before parts ship. This inspection discipline aligns with buyer expectations for process control and reduces the risk of costly returns or corrective actions. For manufacturers comparing suppliers, visible quality verification often outweighs aggressive pricing when evaluating long-term sourcing partners.

Trustbridge Tip: Precision in individual operations like counterbore execution strengthens a supplier’s reputation for consistency, but long-term resilience comes from strategic supplier management at scale. Modern supply chains increasingly rely on smarter supplier segmentation and AI-enhanced risk insights to anticipate disruptions and maintain continuity across diverse manufacturing demands. By combining disciplined machining processes with data-driven supplier segmentation and predictive analytics, suppliers not only deliver quality parts but also demonstrate the operational foresight buyers value most. To explore how strategic segmentation and AI contribute to resilient supplier networks, read our blog: Can Smarter Supplier Segmentation Build Supply Chain Resilience?

Counterbores in Small Batch Manufacturing Environments

Short-run and prototype work frequently exposes weaknesses in counterbore processes. Frequent setup changes, varied designs, and low volumes make consistency more challenging. Suppliers who succeed in small batch manufacturing typically rely on standardized tooling, repeatable setups, and reusable programming templates.

By documenting proven counterbore parameters and reapplying successful strategies, suppliers reduce setup time and variability. This approach improves quoting confidence, protects margins, and ensures predictable quality even when designs change and volumes remain low.

How Counterbore Quality Influences Buyer Decisions

Manufacturers increasingly evaluate suppliers based on downstream performance rather than inspection reports alone. Counterbores that cause uneven clamping, assembly delays, or fastener issues quickly erode supplier credibility. In contrast, parts that assemble smoothly reinforce the perception of a low-risk, production-ready supplier.

This perception plays a critical role when buyers shortlist vendors for long-term or higher-value contracts. Strong counterbore execution supports a supplier’s reputation as a precision machining supplier capable of supporting complex assemblies and demanding functional requirements an increasingly important factor in modern supplier selection criteria.

Positioning Counterbore Capability as a Competitive Advantage

Many machining suppliers overlook counterbore operations when marketing their capabilities. However, highlighting disciplined counterbore processes can strengthen positioning particularly for aerospace, industrial, and precision equipment buyers. Clear communication around tooling control, inspection methods, and repeatability reassures buyers that even minor features receive serious attention.

Suppliers who connect counterbore accuracy to assembly efficiency and lifecycle performance differentiate themselves from competitors focused solely on machine count or hourly rates. This positioning aligns technical execution with measurable commercial value.

Conclusion:

For CNC machining services suppliers, counterbore operations are far more than a routine step in the process. They reflect programming discipline, machine control, and a commitment to quality at every level. Suppliers who standardize and validate their counterbore processes improve part functionality, reduce customer friction, and reinforce their standing as reliable machining partners.

As buyers place greater emphasis on predictability and precision, mastering counterbore execution strengthens quoting confidence, supports healthier margins, and builds resilient customer relationships. Suppliers who treat these foundational details as strategic priorities will be best positioned to win higher-value work and long-term trust in an increasingly demanding market.

Frequently Asked Questions

1. What are the most common counterbore mistakes CNC suppliers make?

The most common counterbore issues include inconsistent depth control, tool deflection, poor bottom flatness, and improper tool selection. These mistakes often result in fasteners sitting proud or bottoming out before proper clamping, which can cause assembly problems downstream. For buyers, these issues signal weak process control, even if the rest of the part meets dimensional requirements.

2. How does counterbore depth variation affect part assembly and performance?

Even minor depth variation in a counterbore can lead to uneven fastener seating and improper load distribution. In assemblies, this may cause misalignment, vibration, or premature failure during service. For suppliers providing CNC machining services, maintaining consistent counterbore depth is essential to ensuring parts assemble smoothly without additional adjustment or rework.

3. Why is tool selection critical for accurate counterbore operations?

Using the wrong counterbore tool such as one with inadequate rigidity, poor coating, or incorrect geometry can lead to chatter, tapered walls, or uneven bottoms. Tool wear also plays a significant role, especially in tight-tolerance machining environments. Precision machining suppliers often track tool life specifically for counterbore tools to maintain repeatability across batches and materials.