How Buyers Evaluate POM Plastic Material for Quality, Compliance, and Supplier Performance

For buyers and procurement teams, material selection is no longer just an engineering choice. It is a sourcing decision that affects supplier risk, product reliability, regulatory exposure, and long-term supply continuity. Choosing POM plastic material—also known as polyoxymethylene or acetal—means deciding whether a supplier can consistently deliver parts that behave the same way during early production, scale-up, and long-term use.

POM plastic material is widely used in precision components because it offers strength, dimensional stability, low friction, and wear resistance. However, reviewing a technical datasheet alone does not confirm whether a supplier can control variation, meet compliance expectations, and perform reliably under real production conditions.

Today’s buyers must confirm that suppliers can deliver consistent material behavior, repeatable dimensions, and stable performance across batches and volumes. Weak supplier decisions often surface months after launch, when parts begin to fail in the field or when audits expose gaps in documentation. This is why evaluating POM plastic material from a buyer’s perspective means looking at quality, compliance, and supplier performance together.

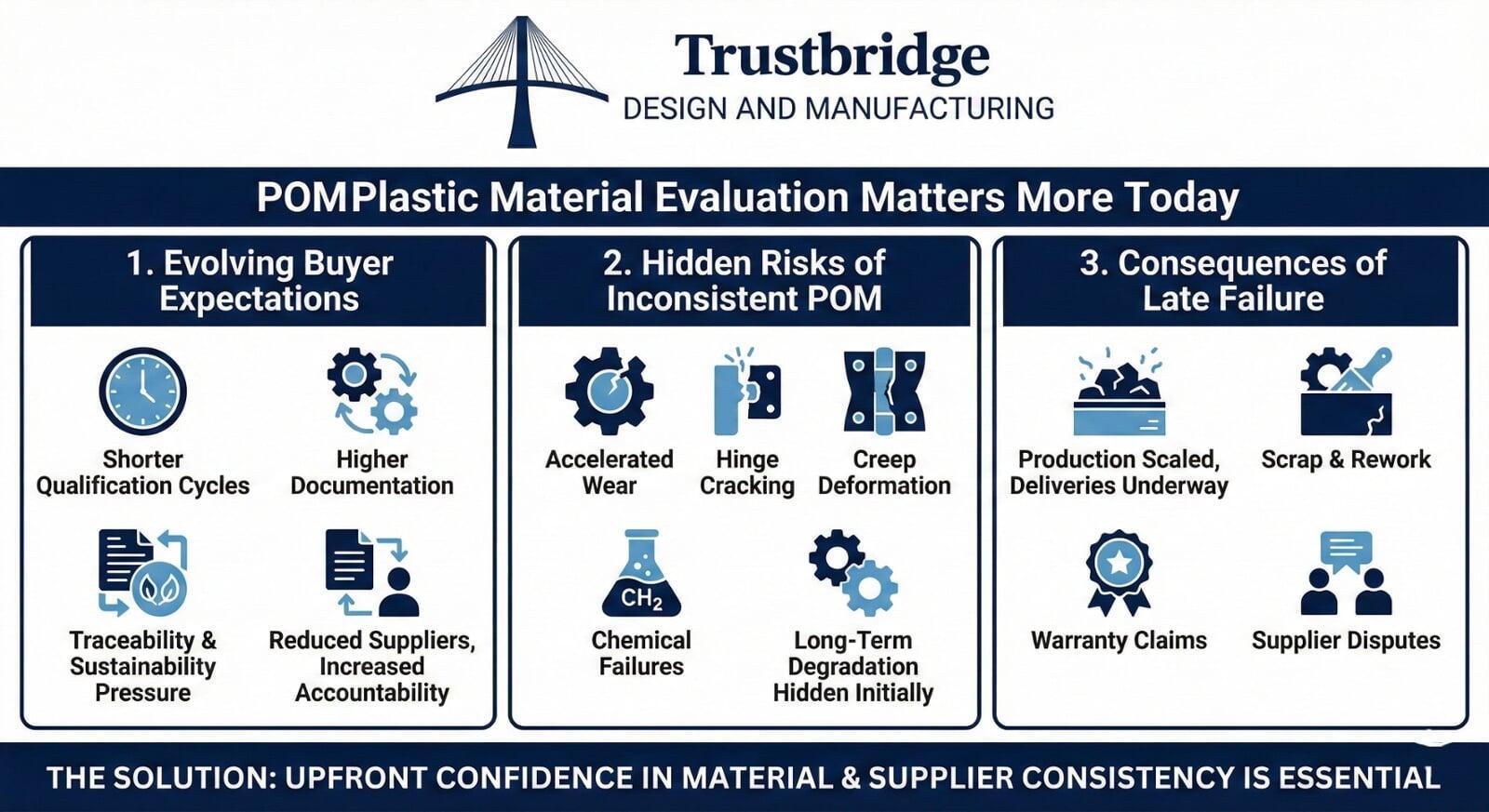

Why Evaluating POM Plastic Material Matters More Today

Buyer expectations around engineered plastics have changed in specific ways. Qualification cycles are shorter, documentation requirements are higher, and buyers are under pressure to prove traceability, sustainability, and process control. Many organizations are also reducing supplier counts while increasing accountability from the suppliers they retain.

In this environment, material problems carry greater risk. Inconsistent POM batches can lead to accelerated gear wear, hinge cracking, creep deformation under load, or chemical resistance failures. These issues often do not appear during early testing. POM typically performs well at first, which can hide long-term degradation until parts are exposed to heat, stress, and extended operating cycles.

By the time failures become visible, production is already scaled and customer deliveries are underway. Fixing these issues late often results in scrap, rework, warranty claims, and supplier disputes. Buyers now need confidence upfront that both the material and the supplier can perform consistently over time.

Trustbridge Tip: Look Beyond Early Performance Signals

Many POM parts perform well during early testing, which can hide long-term risks such as creep, wear, or chemical degradation. Buyers who account for how materials behave after extended cycles are better positioned to prevent late-stage failures. Similar challenges appear in early OEM programs, where initial validation does not always reflect scaled production realities, as seen in discussions around low-volume injection molding and PPAP readiness in early manufacturing stages.

Why Buyers Rely on POM Plastic Material in Critical Applications

POM plastic material is commonly used in parts that require strength, low friction, fatigue resistance, chemical resistance, and tight tolerances. Gears, bushings, clips, and load-bearing structural components made from acetal often perform functional roles inside assemblies. When these parts fail, the entire product can be affected.

For buyers, the value of polyoxymethylene lies in predictability. When processed correctly, it delivers repeatable performance and long service life. However, when suppliers lack experience with this engineered plastic, problems such as internal stress, warping, surface instability, or early wear can occur.

Processing expertise matters because POM is sensitive to cooling rates, mold design, moisture control, and machining conditions. Small variations in these areas can affect how parts perform over time.

Trustbridge Tip: Use Digital Tools to Reduce Risk Without Slowing Decisions

Supplier evaluation does not need to slow sourcing decisions. Buyers who rely on structured data such as inspection histories, compliance records, and performance trends can identify risks earlier without adding friction. This mirrors how digital procurement tools help reduce supplier risk while maintaining decision speed by improving visibility across suppliers.

Processing Knowledge and Part Performance

POM has relatively high shrinkage, is sensitive to cooling speed, and can warp if thermal conditions are not managed carefully. Buyers look for suppliers who understand mold venting, cooling balance, machining speeds, and moisture control specific to polyoxymethylene.

Suppliers with strong process knowledge produce parts that maintain performance throughout their service life, reducing warranty risk and minimizing field failures.

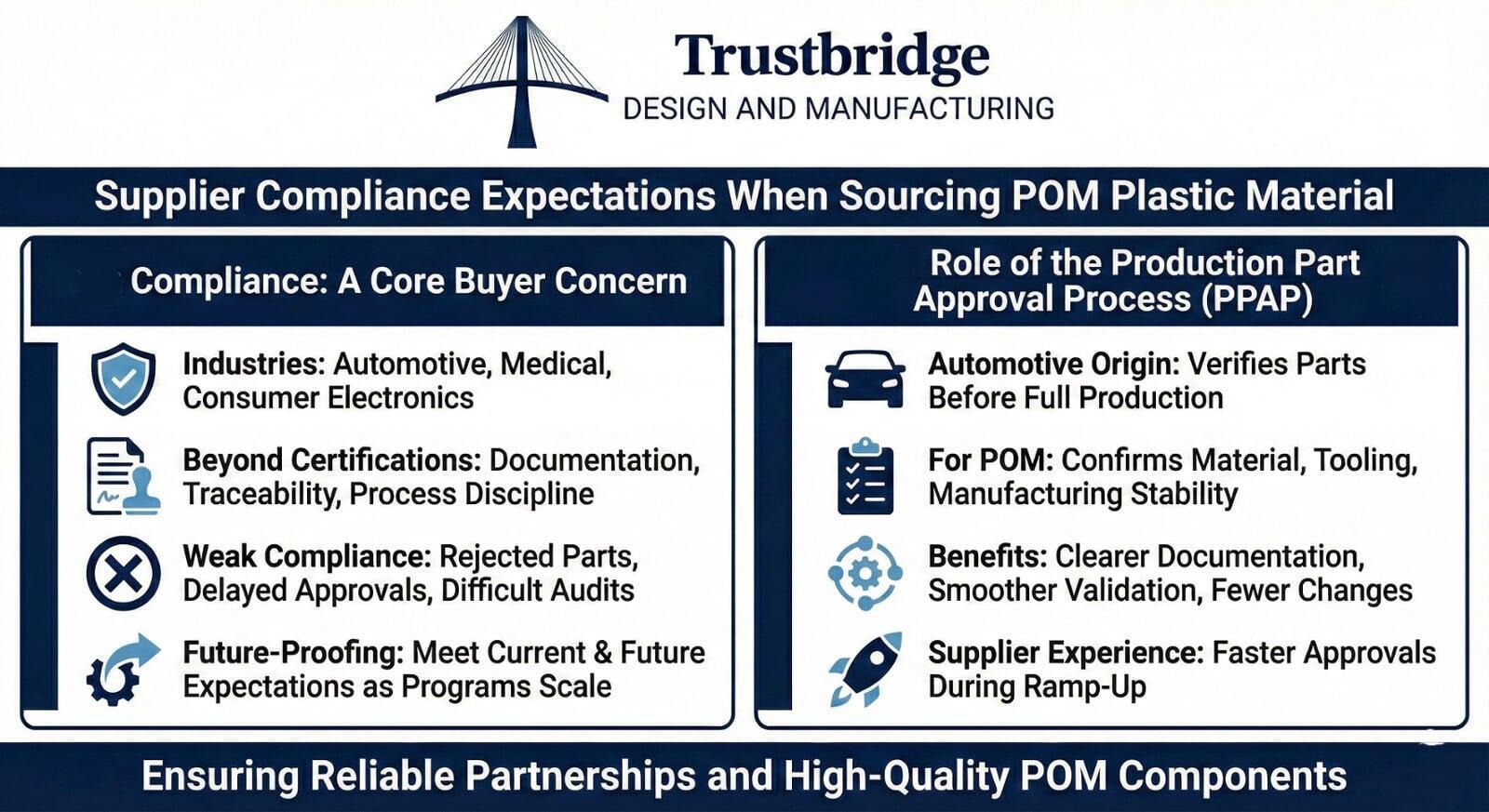

Supplier Compliance Expectations When Sourcing POM Plastic Material

Compliance is a core concern for buyers, especially in industries such as automotive, medical devices, and consumer electronics. Supplier compliance goes beyond holding certifications. It reflects how well documentation, traceability, and process discipline are managed.

Weak compliance practices often lead to rejected parts, delayed approvals, and difficult audit findings. Buyers must confirm that suppliers can meet both current and future compliance expectations as programs scale or regulations change.

Role of the Production Part Approval Process (PPAP)

The production part approval process (PPAP), originally established in the automotive industry, helps buyers verify that parts meet requirements before full production begins. For POM components, PPAP confirms that the material, tooling, and manufacturing processes are stable and repeatable.

Suppliers experienced with PPAP submissions for acetal parts typically provide clearer documentation, smoother tooling validation, fewer engineering changes, and faster approvals during ramp-up.

Buyers can reduce supplier risk without slowing sourcing decisions by relying on structured data such as inspection history, compliance records, and approval trends. This mirrors how digital procurement tools help buyers act faster while maintaining control.

Ongoing Traceability and Audit Readiness

Compliance does not end after initial approval. Buyers expect suppliers to maintain lot-level traceability, resin certificates, process logs, and controlled change records throughout the product lifecycle.

Audit-ready suppliers keep documentation organized, follow standard operating procedures, and maintain consistent records. This protects buyers from last-minute disruptions that can affect customers, regulators, and internal teams.

Measuring Supplier Performance Beyond Material Quality

Even when POM plastic material meets specifications, supplier performance still determines success. Buyers evaluate how suppliers perform over time, not just during first articles or PPAP approval.

Key performance areas include delivery reliability, responsiveness, process stability, and cost control.

Lead Time Reliability and Delivery Stability

Reliable lead times allow buyers to plan production accurately and manage lean inventories. Missed deliveries or frequent schedule changes create downstream disruptions and increase internal costs.

Supplier Scorecards and Accountability

Supplier scorecards help buyers track quality, delivery, and responsiveness across programs. These metrics reveal patterns that single inspections cannot. Suppliers with strong scorecard performance typically invest in process control and communication.

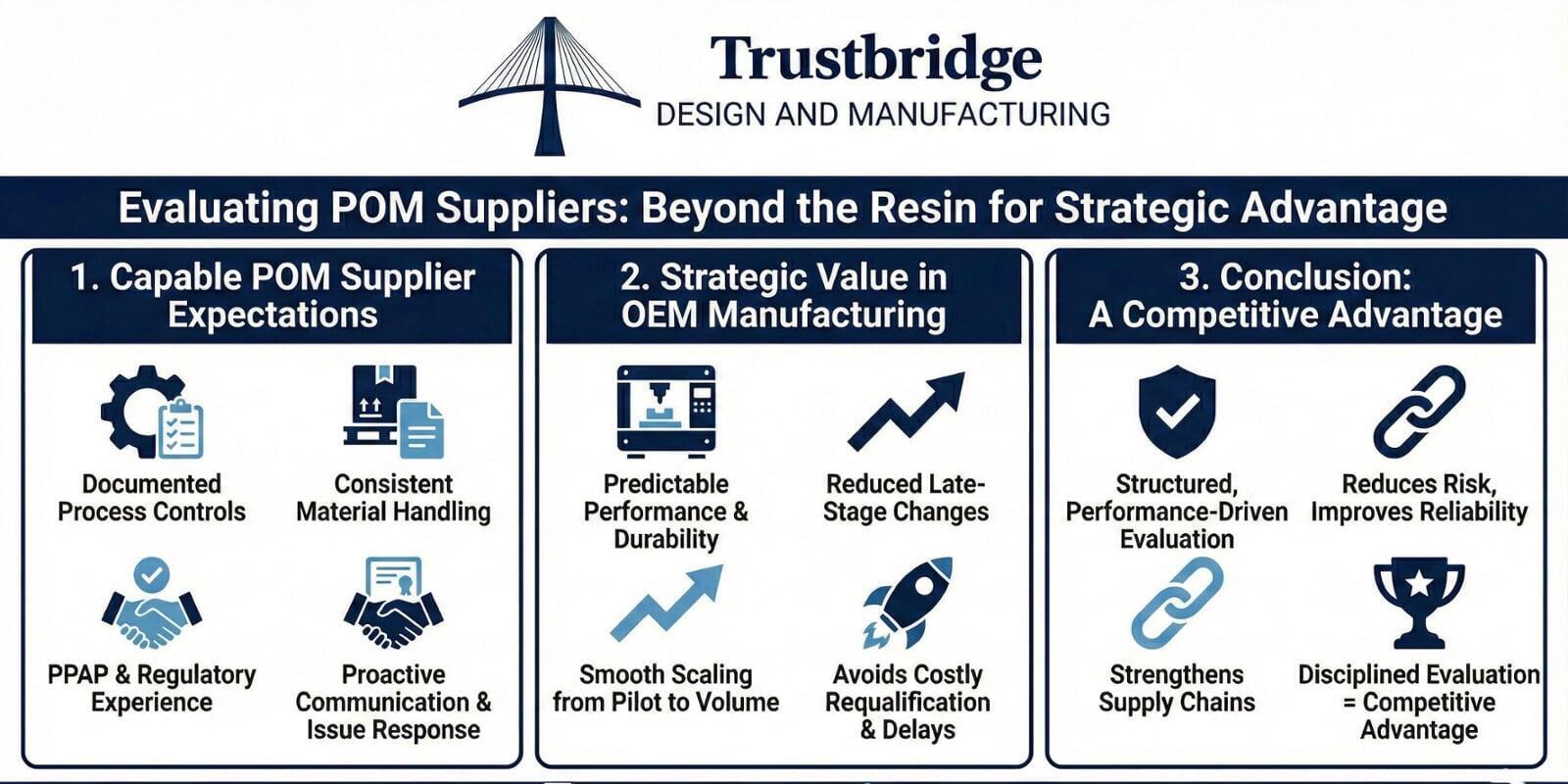

What Buyers Should Expect From a Capable POM Supplier

A capable POM supplier does more than ship parts. Buyers should expect documented process controls, consistent material handling, audit-ready documentation, and experience supporting PPAP and regulatory requirements.

Suppliers who understand polyoxymethylene applications anticipate risks early, communicate clearly, respond quickly to issues, and support design changes and scaling decisions. This maturity reduces sourcing risk and strengthens long-term supplier relationships.

Strategic Value of POM Plastic Material in OEM Manufacturing

When sourced correctly, acetal components support reliable OEM manufacturing by combining durability with predictable performance. Buyers who align material selection with supplier capability reduce late-stage changes and improve launch outcomes.

Evaluating suppliers early allows buyers to build partnerships that scale smoothly from pilot production to full volumes, avoiding costly requalification efforts and production delays.

Conclusion

Evaluating POM plastic material is no longer just about choosing the right resin. For buyers, it means selecting suppliers who can deliver consistent quality, maintain compliance, and perform reliably over time. Weak supplier controls often surface only after production is underway, when changes are expensive and disruptive.

Buyers who take a structured, performance-driven approach to evaluating POM suppliers reduce risk, improve product reliability, and strengthen their supply chains. In today’s sourcing environment, disciplined supplier evaluation is not optional—it is a competitive advantage.

If you are sourcing POM plastic material today, take a practical next step before issues surface later. Review how your current suppliers manage material consistency, processing controls, and compliance readiness—not just during initial approval, but throughout ongoing production.

Consider requesting a supplier capability review, asking for recent PPAP documentation, or validating how traceability and inspection data are maintained over time. These checks help identify gaps early, when corrective action is still manageable.

A short evaluation now can prevent costly quality issues later and help build supplier relationships that perform reliably as programs scale.

Frequently Asked Questions (FAQs)

1. Why can POM plastic material pass early tests but fail later in production?

POM often performs well during initial validation, but long-term issues like creep, wear, or dimensional drift can appear under sustained load or temperature. These failures are usually caused by inconsistent processing rather than the resin itself.

2. What does material consistency mean when buyers evaluate POM plastic material?

Material consistency means predictable dimensions, mechanical properties, and performance across batches and production runs. Even small variations in POM parts can lead to assembly problems or uneven wear.

3. Why is supplier processing knowledge critical for POM plastic material?

POM is sensitive to molding, cooling, and moisture control. Suppliers without strong process discipline can introduce internal stress or instability, which affects long-term part performance.

4. How does PPAP help buyers reduce risk when sourcing POM plastic material?

PPAP confirms that the material, tooling, and process can repeatedly meet requirements before full production. It helps buyers identify quality and consistency issues early, when they are easier to correct.