AI in Manufacturing Is Revolutionizing Supplier Operations and Boosting Efficiency in These 5 Ways (and More)

AI in manufacturing is no longer a future-facing concept reserved for innovation labs. It is now a competitive requirement shaping how suppliers quote, produce, inspect, and deliver. As OEMs push for faster turnaround, tighter tolerances, and greater transparency, suppliers are expected to demonstrate both speed and smart operational control. AI is redefining supplier operations by transforming CNC machining services, quality workflows, and supplier relationship management into data-driven, predictive systems that strengthen reliability and trust across the supply chain.

Why AI in Manufacturing Has Become a Supplier Imperative

AI in manufacturing has moved from experimentation to execution because traditional supplier workflows can no longer keep pace with market expectations. Manual planning creates blind spots. Reactive quality control increases rework. Static supplier data makes it difficult to respond quickly to change. Together, these limitations expose suppliers to delays, cost overruns, and inconsistent outcomes.

Suppliers are now evaluated on how effectively they anticipate risk, adapt workflows, and maintain consistency across increasingly complex production environments. AI gives suppliers a structural advantage by enabling smarter decisions across machining, inspection, scheduling, and communication. Rather than reacting to problems after they occur, AI-powered supplier operations focus on preventing disruptions before they impact delivery schedules or part quality. This shift is reshaping how buyers assess supplier readiness and long-term manufacturing reliability.

AI-Driven CNC Machining Services Are Redefining Production Efficiency

AI-driven CNC machining services are fundamentally changing how suppliers manage machine utilization, programming accuracy, and throughput. Traditional CNC environments rely heavily on operator experience and historical norms. AI replaces intuition-based decisions with predictive analytics and real-time optimization, creating a more consistent and controllable production environment.

By integrating AI into CNC machine and programming workflows, suppliers can dynamically adjust feeds, speeds, and tool paths throughout a run. This reduces tool wear, prevents collisions, and improves surface finish consistency. As a result, many suppliers see measurable improvements such as lower scrap rates and shorter cycle times, giving them a clear advantage when competing for precision-driven programs.

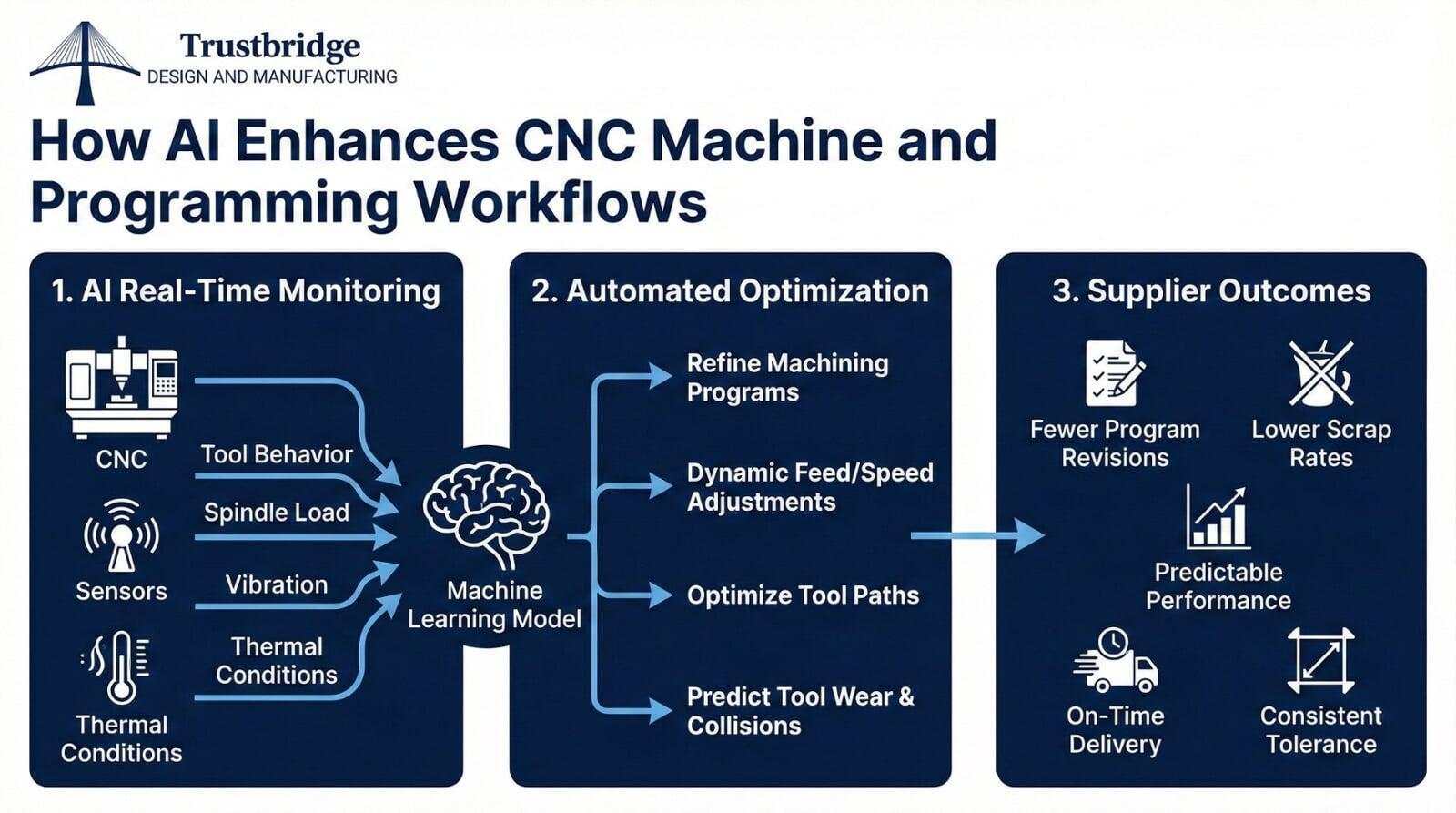

How AI Enhances CNC Machine and Programming Workflows

AI actively monitors CNC operations to uncover inefficiencies that human operators might miss. Machine learning models analyze tool behavior, spindle load, vibration patterns, and thermal conditions to automatically refine machining programs. Over time, these systems learn which strategies produce the most stable results for specific materials and geometries.

For suppliers, this translates into fewer program revisions, lower scrap rates, and more predictable machining performance—delivering parts on time, within tolerance, and without last-minute corrections that disrupt schedules or erode buyer confidence.

AI Is Transforming Supplier Quote Turnaround and Capacity Planning

AI-powered supplier operations dramatically accelerate CNC quote turnaround, a process historically slowed by manual cost estimation and tribal knowledge. Instead of relying on spreadsheets and assumptions, AI analyzes historical job data, real-time machine availability, material usage patterns, and labor constraints in seconds.

This allows suppliers to respond to RFQs with confidence rather than approximation. AI-driven capacity planning replaces gut-based scheduling with data-backed optimization, balancing workloads across machines and shifts. The result is fewer overcommitted schedules, fewer missed delivery dates, and far fewer surprises for OEMs after purchase orders are issued.

AI-Driven Quality Inspection and CMM Workflows Reduce Downstream Risk

AI delivers some of its most powerful supplier-side value in quality control by identifying issues earlier in the production lifecycle. Traditional inspection often catches problems only after parts are complete, leading to scrap, rework, or shipment delays. AI-driven quality inspection and coordinate measuring machine workflows move quality upstream.

By correlating machining signals—such as tool wear trends or thermal drift—with inspection data, AI can flag early indicators of issues like dimensional drift or surface finish degradation. This allows suppliers to intervene before tolerances are exceeded, preserving both yield and delivery commitments.

AI-Enabled Coordinate Measuring Machine Integration

AI-enhanced coordinate measuring machine workflows combine automated inspection planning with adaptive measurement strategies that respond to part complexity and historical defect trends. Instead of static inspection routines, AI prioritizes critical features based on real risk patterns, accelerating inspection while improving insight quality.

For buyers, this results in stronger confidence in supplier inspection rigor, fewer quality escapes during production ramps, and smoother audit and qualification processes.

AI-Enabled Supplier Relationship Management Improves Transparency

Supplier relationship management has traditionally centered on contracts, certifications, and periodic performance reviews. AI-enabled supplier.

relationship management transforms this static model into a continuous, data-driven performance view. Suppliers using AI can track delivery accuracy, quality trends, and responsiveness in real time, creating a clearer operational picture for decision-makers.

This transparency benefits both sides. Buyers gain earlier visibility into performance risks, while suppliers can address issues before they escalate. AI in manufacturing shifts supplier relationships from reactive problem-solving to proactive collaboration, supporting long-term sourcing stability and stronger partnerships.

Real-World Impact of AI in Supplier Operations

The impact of AI-powered supplier operations is measurable and practical. A mid-sized machining supplier that integrated AI into its CNC machining and inspection workflows reduced scrap rates by 15 percent and improved on-time delivery by more than 20 percent within a year. These improvements directly strengthened margins and customer retention.

The gains did not come from new equipment, but from smarter use of data. AI helped the supplier identify recurring issues such as tool wear variability and inspection bottlenecks, standardize best-performing processes, and scale output without compromising quality. Suppliers that invest in AI-driven machining, inspection, and relationship management clearly signal operational maturity and readiness for complex, tolerance-sensitive programs.

Preparing Supplier Operations for an AI-Driven Manufacturing Future

AI adoption is not a one-time upgrade but a continuous transformation. To fully capture the benefits of AI in manufacturing, suppliers must align data infrastructure, workforce skills, and process governance. This includes embedding AI across machining, quality, production planning, and customer communication workflows.

Suppliers that approach AI strategically position themselves as long-term partners rather than transactional vendors. AI becomes the foundation for scalable operations, stronger compliance, and continuous improvement helping suppliers meet today’s requirements while preparing for the demands of tomorrow.

Trustbridge Tip: AI helps suppliers predict outcomes, but risk is still best managed before scale. Small-batch manufacturing allows OEMs to validate supplier process stability, quality systems, and decision-making under real production conditions—without the exposure of high-volume commitments. To see how small-batch manufacturing reduces supplier risk compared to high-volume sourcing, read our blog How Does Small-Batch Manufacturing Reduce Risk for OEMs Compared to High-Volume Suppliers.

Conclusion

AI in manufacturing is reshaping supplier operations from the shop floor to supplier relationship management. From AI-driven CNC machining services and quality inspection to faster quoting and stronger compliance readiness, the impact is measurable and lasting.

Now is the time to assess how AI can enhance your own operations or your supplier network. Don’t just review equipment lists and certifications. Evaluate how suppliers use AI to optimize workflows, control quality, and deliver predictable outcomes. The suppliers investing in AI today are the ones building resilient, future-ready manufacturing partnerships tomorrow.

If you are sourcing CNC machining services, managing PPAP approvals, or evaluating supplier performance, start asking deeper questions. How are your suppliers using AI in manufacturing to reduce risk, accelerate timelines, and improve consistency?

Partner with AI-powered suppliers that combine advanced technology with proven process control to build a supply chain that performs reliably today and scales confidently for tomorrow.

Frequently Asked Questions (FAQs)

1. Why is AI in manufacturing becoming essential for suppliers, not optional?

AI in manufacturing is essential because buyers now evaluate suppliers on speed, predictability, and process intelligence—not just capacity. AI helps suppliers optimize CNC machining services, improve quote accuracy, and prevent quality issues before they affect delivery. Without AI, suppliers struggle to meet modern OEM expectations.

2. How does AI improve CNC machining services and programming workflows?

AI enhances CNC machine and programming workflows by analyzing spindle load, vibration, tool wear, and thermal data in real time. This allows suppliers to optimize feeds, speeds, and tool paths automatically, reducing scrap, stabilizing cycle times, and improving surface finish consistency across machined parts.

3. What impact does AI have on quality inspection and CMM workflows?

AI-driven quality inspection and CMM workflows shift quality control from reactive to predictive. By correlating machining data with inspection results, AI identifies early signals of deviation, allowing suppliers to correct issues before parts fall out of tolerance or require rework.

4. How does AI strengthen supplier relationship management for OEMs?

AI-enabled supplier relationship management provides continuous visibility into delivery performance, quality trends, and responsiveness. This transparency helps OEMs make better sourcing decisions while enabling suppliers to demonstrate reliability, prove operational maturity, and build long-term partnerships instead of transactional relationships.