Small Batch Manufacturing: How Small Machine Shops Compete and Win Against Large Manufacturers

Small machine shops often assume they are at a disadvantage when competing against large manufacturers with massive capacity, global footprints, and deep capital reserves. That assumption is outdated.

For suppliers, success today is not about producing the most parts at the lowest theoretical cost. It is about reducing OEM risk while accelerating production readiness. Meeting expectations around agility, responsiveness, and controlled execution now outweighs raw output.

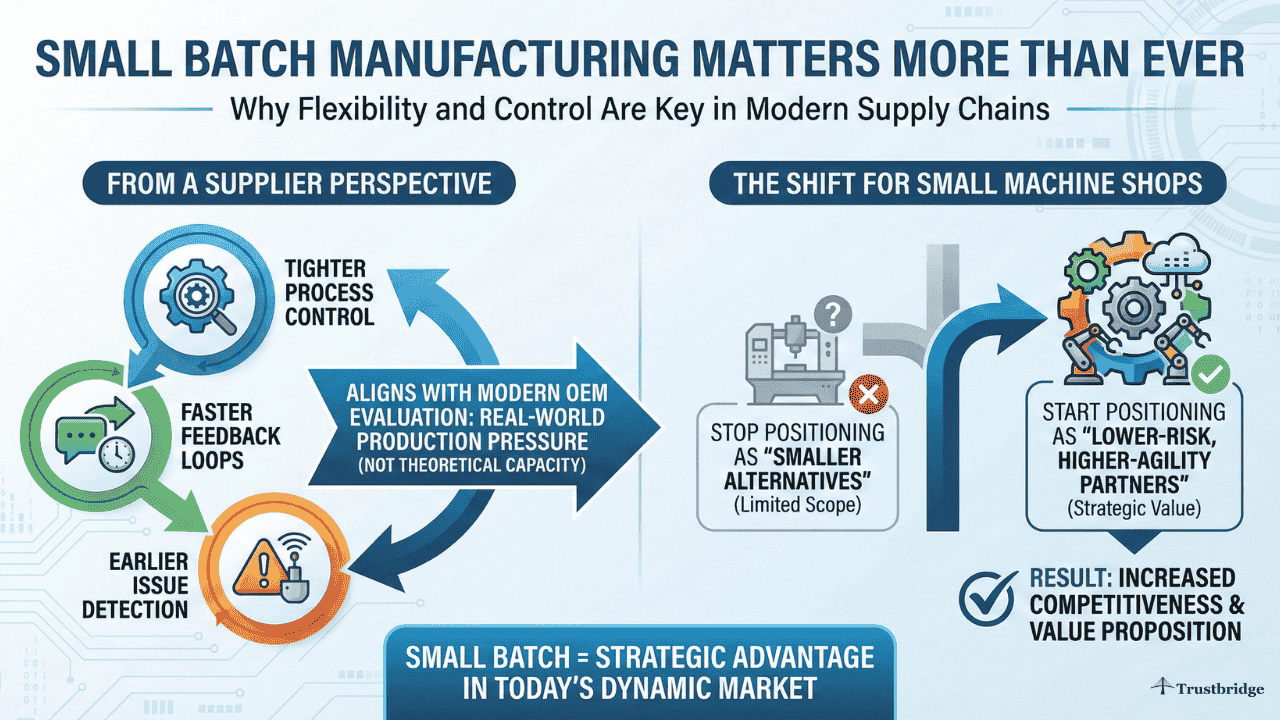

Why Small Batch Manufacturing Matters More Than Ever

Small batch manufacturing has evolved from a stopgap solution into a strategic sourcing model. OEMs now operate in environments defined by volatile demand, frequent design changes, and compressed timelines—conditions where large, inflexible production runs increase risk rather than reduce cost.

From a supplier perspective, small batch manufacturing enables tighter process control, faster feedback loops, and earlier issue detection. These advantages directly align with how modern OEMs evaluate suppliers under real-world production pressure, not theoretical capacity models.

Small machine shops that understand this shift stop positioning themselves as “smaller alternatives” and start positioning themselves as lower-risk, higher-agility partners.

How OEM Buyer Behavior Has Changed

OEM sourcing teams no longer evaluate suppliers on capacity alone. Today’s supplier selection criteria emphasize responsiveness, communication quality, and the ability to absorb change without disruption.

Small batch manufacturing supports this behavior shift by enabling suppliers to deliver production-ready parts without long ramp-up cycles or rigid scheduling constraints. This flexibility is especially critical during early production phases, engineering changes, and low-to-mid volume programs where uncertainty is highest.

Large manufacturers often struggle here due to fixed overhead, layered approvals, and standardized workflows. Small shops, by contrast, can adapt faster because decision-making and execution live closer together.

Supplier Selection Criteria Favoring Small Shops

OEMs increasingly favor suppliers that can support variable volumes, shorter lead times, and rapid iteration without friction. These expectations align naturally with small batch manufacturing environments, where systems are built for adaptability rather than scale efficiency alone.

This is why small machine shops frequently outperform larger competitors in early-stage production, bridge manufacturing, and specialized programs where responsiveness outweighs volume economics.

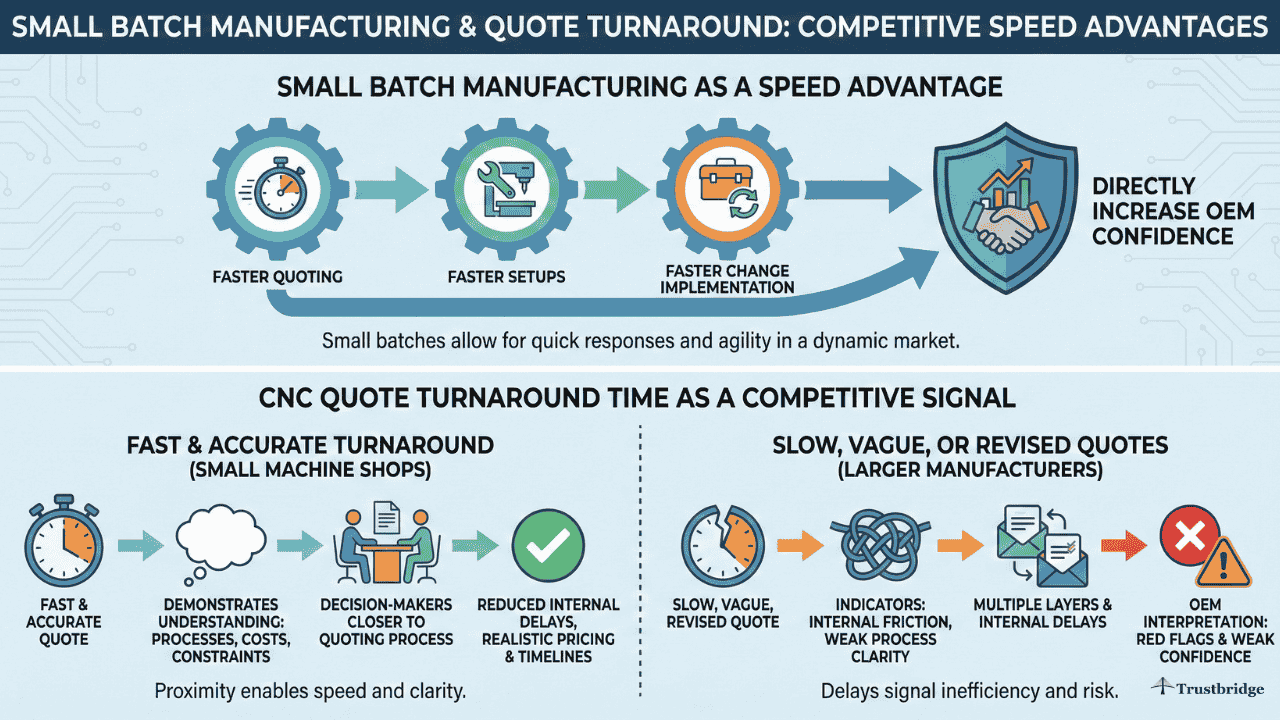

Small Batch Manufacturing as a Speed Advantage

Speed is one of the most undervalued competitive advantages small shops hold over large manufacturers. Faster quoting, faster setups, and faster change implementation directly increase OEM confidence.

Small batch manufacturing reduces internal complexity. Fewer approval layers, shorter setup cycles, and tighter coordination between engineering and production allow small shops to move quickly without sacrificing control or quality.

This speed becomes immediately visible during CNC quote turnaround time, often the first real signal OEMs use to judge supplier responsiveness.

CNC Quote Turnaround Time as a Competitive Signal

Fast and accurate CNC quote turnaround time signals far more than efficiency. It demonstrates that a supplier understands its processes, costs, and constraints.

Small machine shops frequently outperform larger manufacturers because decision-makers sit closer to the quoting process. This proximity reduces internal delays and enables realistic pricing and timelines from the outset.

OEMs routinely interpret slow, vague, or revised quotes as indicators of internal friction or weak process clarity—red flags early in the sourcing cycle.

Custom Manufacturing Over Mass Production

Large manufacturers are optimized for repetition. Small shops are optimized for variation. In markets where OEM designs evolve continuously, custom manufacturing becomes a strategic advantage, not a limitation.

Small batch manufacturing allows suppliers to adapt tooling, processes, and inspection strategies without disrupting large production systems. This flexibility reduces change-related risk for OEMs and shortens development cycles.

Custom manufacturing also enables closer collaboration between suppliers and OEM engineering teams, strengthening long-term technical and commercial relationships.

Engineering Collaboration in Small Batch Environments

Small machine shops often work directly with OEM engineers to improve manufacturability early. This collaboration leads to higher-quality parts, fewer revisions, and reduced downstream failures.

Large manufacturers may lack the incentive or bandwidth to engage this deeply—especially on lower-volume programs making small shops more valuable partners during critical early stages.

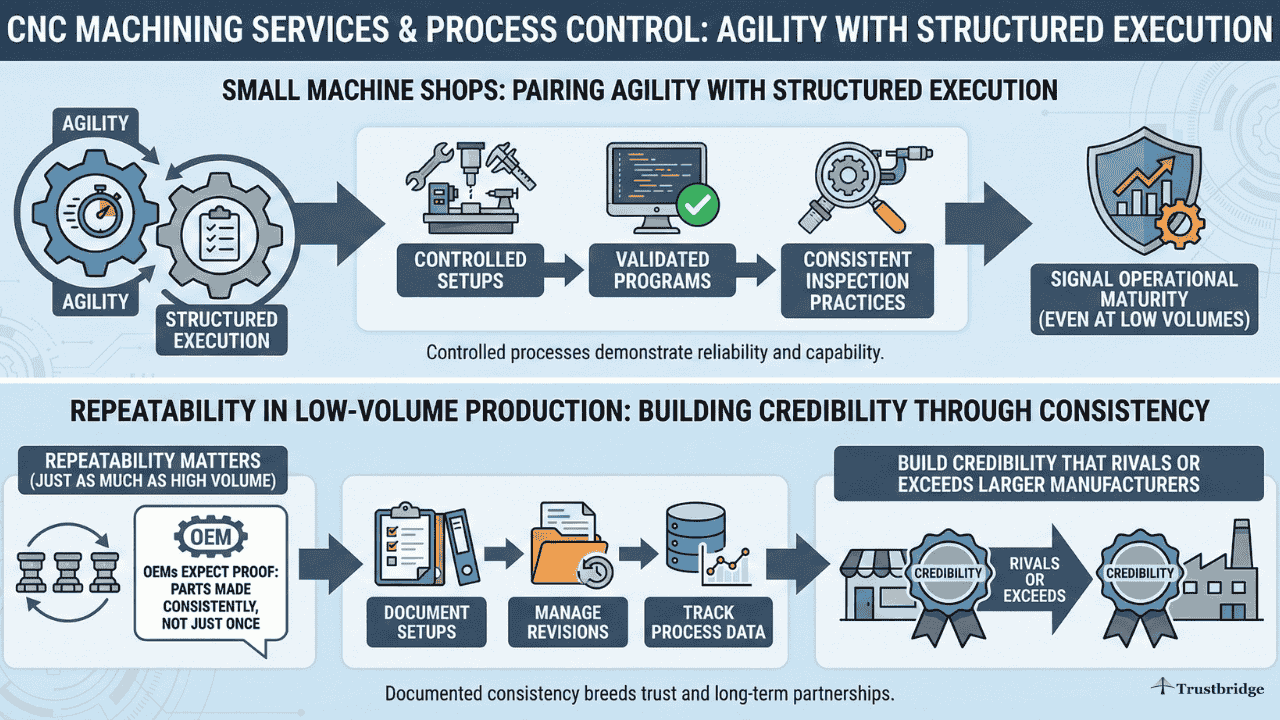

CNC Machining Services and Process Control

Winning small batch manufacturing work requires more than flexibility. OEMs still demand disciplined CNC machining services that deliver repeatable, production-ready outcomes.

Small machine shops succeed when they pair agility with structured execution. Controlled setups, validated programs, and consistent inspection practices signal operational maturity, even at low volumes.

OEMs are often less forgiving of inconsistency in small batches because early-stage failures carry outsized downstream risk.

Repeatability in Low-Volume Production

Repeatability matters just as much in small batch manufacturing as it does in high-volume production. OEMs expect proof that parts can be made consistently—not just successfully once.

Small shops that document setups, manage revisions, and track process data build credibility that rivals or exceeds much larger manufacturers.

Machine Shop Pricing and Value Perception

Machine shop pricing is frequently misunderstood when small suppliers compete against large manufacturers. Lowest price rarely wins OEM trust. Predictable pricing, transparent assumptions, and minimal downstream surprises matter more.

Small batch manufacturing allows suppliers to price work based on actual process costs, not volume-based assumptions. This leads to greater pricing accuracy and fewer disputes later.

OEMs value suppliers who deliver exactly what they quote without constant renegotiation.

Why Predictable Pricing Beats Lowest Price

Large manufacturers may offer lower unit prices but often introduce rigidity, long lead times, or costly change fees. Small shops that communicate pricing clearly and manage expectations deliver higher total value over time.

OEM buyers remember suppliers who prevent surprises, not those who simply quote low.

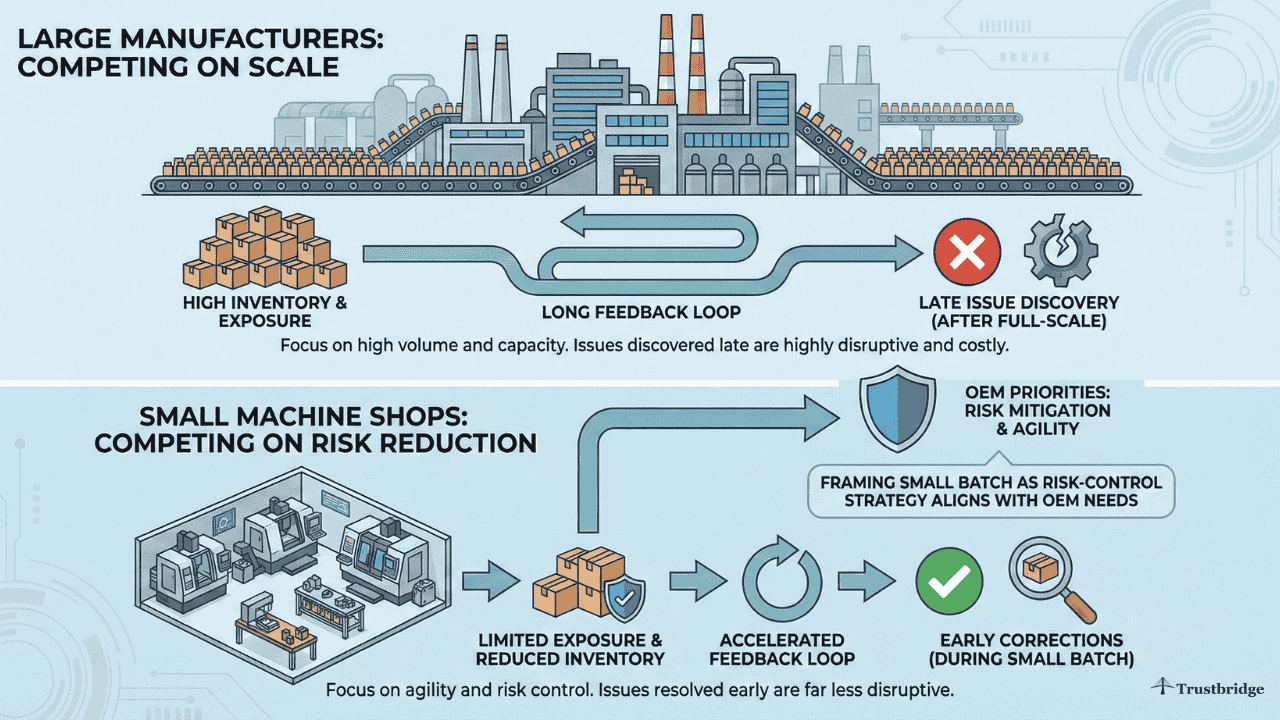

Competing on Risk Reduction, Not Scale

Large manufacturers compete on scale. Small machine shops compete on risk reduction.

Small batch manufacturing inherently limits exposure by reducing inventory, accelerating feedback, and enabling early corrections.

OEMs understand that resolving issues in small batches is far less disruptive than correcting problems discovered after full-scale production.

Suppliers that frame small batch manufacturing as a risk-control strategy, not a capacity constraint, align directly with OEM priorities.

Early Production Confidence

Small batch manufacturing enables OEMs to validate performance, fit, and assembly under real conditions before scaling. Suppliers who support this approach become trusted partners, not interchangeable vendors.

Long-Term Supplier Relationships Start Small

Many long-term OEM supplier relationships begin with small batch manufacturing. Early programs test communication, responsiveness, and problem-solving—not just technical capability.

Small machine shops often excel because leadership, engineering, and production are tightly connected. Issues surface quickly and are resolved visibly, building trust early.

Large manufacturers may struggle to offer the same attention to smaller programs.

Growing With OEM Programs

Suppliers that succeed in small batch manufacturing are frequently invited into future programs, higher volumes, or additional components. OEMs prefer to grow with partners they already trust.

Trustbridge Tip: In small batch manufacturing, flexibility alone is not enough—buyers prioritize process control and repeatability. CNC router machining is often how OEMs evaluate new suppliers, focusing on quoting discipline, programming stability, and consistent output at low volumes. Shops that deliver reliable CNC machining services and predictable CNC quote turnaround time consistently stand out as lower-risk partners. To see how buyers evaluate CNC router suppliers, read our guide: Buyer’s Guide to CNC Router Machining: How to Select the Right Supplier for Precision Machined Parts.How to Select the Right Supplier for Precision Machined Parts.

Conclusion: Why Small Batch Manufacturing Levels the Playing Field

Small batch manufacturing has fundamentally changed how small machine shops compete. Speed, flexibility, and execution reliability now outweigh raw capacity in many OEM sourcing decisions.

By mastering custom manufacturing, disciplined CNC machining services, fast CNC quote turnaround time, and transparent machine shop pricing, small suppliers position themselves as low-risk, high-value partners.

In today’s manufacturing environment, adaptability and consistency matter more than size. Small machine shops that embrace small batch manufacturing do not just compete with large manufacturers—they outperform them where it matters most.

If your shop specializes in small batch manufacturing and wants to win more OEM programs without competing on scale alone, now is the time to position yourself as a low-risk, high-response supplier. Buyers are actively seeking machine shops that deliver fast CNC quote turnaround time, predictable machine shop pricing, and production-ready CNC machining services for custom manufacturing needs.

Make sure your capabilities, processes, and responsiveness clearly signal that you are built for how OEMs source today—not how they sourced a decade ago.

Frequently Asked Questions (FAQs)

1. What is small batch manufacturing, and why are OEMs prioritizing it today?

Small batch manufacturing involves producing limited quantities of parts with strong process control and fast feedback. OEMs prioritize it because demand is volatile, designs change frequently, and the cost of late-stage failures is high. Small batches reduce risk by allowing OEMs to validate production readiness before committing to scale.

2.How does small batch manufacturing reduce risk for OEMs?

Small batch manufacturing limits exposure by surfacing issues early—before tooling, inventory, and schedules are locked in. Problems related to tolerances, materials, or assembly are faster and cheaper to fix in small batches, making this approach far less disruptive than correcting failures after full-scale production.

3. Why do small machine shops often outperform large manufacturers in small batch work?

Small machine shops are built for flexibility. With fewer approval layers and tighter coordination between engineering and production, they respond faster to changes. Large manufacturers, optimized for repetition and scale, often struggle to deliver the same speed and attention at low-to-mid volumes.