Nonferrous Metals in Manufacturing: Supplier Advantages, Machining Considerations & OEM Applications

Choosing the right cnc router machining supplier is one of the most strategic decisions an OEM buyer can make. Precision machined parts from CNC routers are often mission-critical components in OEM manufacturing, powering products from aerospace systems to industrial equipment. A poor supplier choice can mean inconsistent tolerances, delayed production, and ballooning costs. Unlike commodity purchases, precision machining demands disciplined quality systems, traceability, and strong communication throughout the part lifecycle.

Selecting the right supplier is not just about price or capacity—it’s about risk mitigation, process stability, and long-term partnership. Buyers must evaluate technical capability alongside compliance, quality systems, and supplier performance history to ensure the parts they source consistently meet specifications and delivery expectations.

What CNC Router Machining Is and Why It’s Critical for Buyers

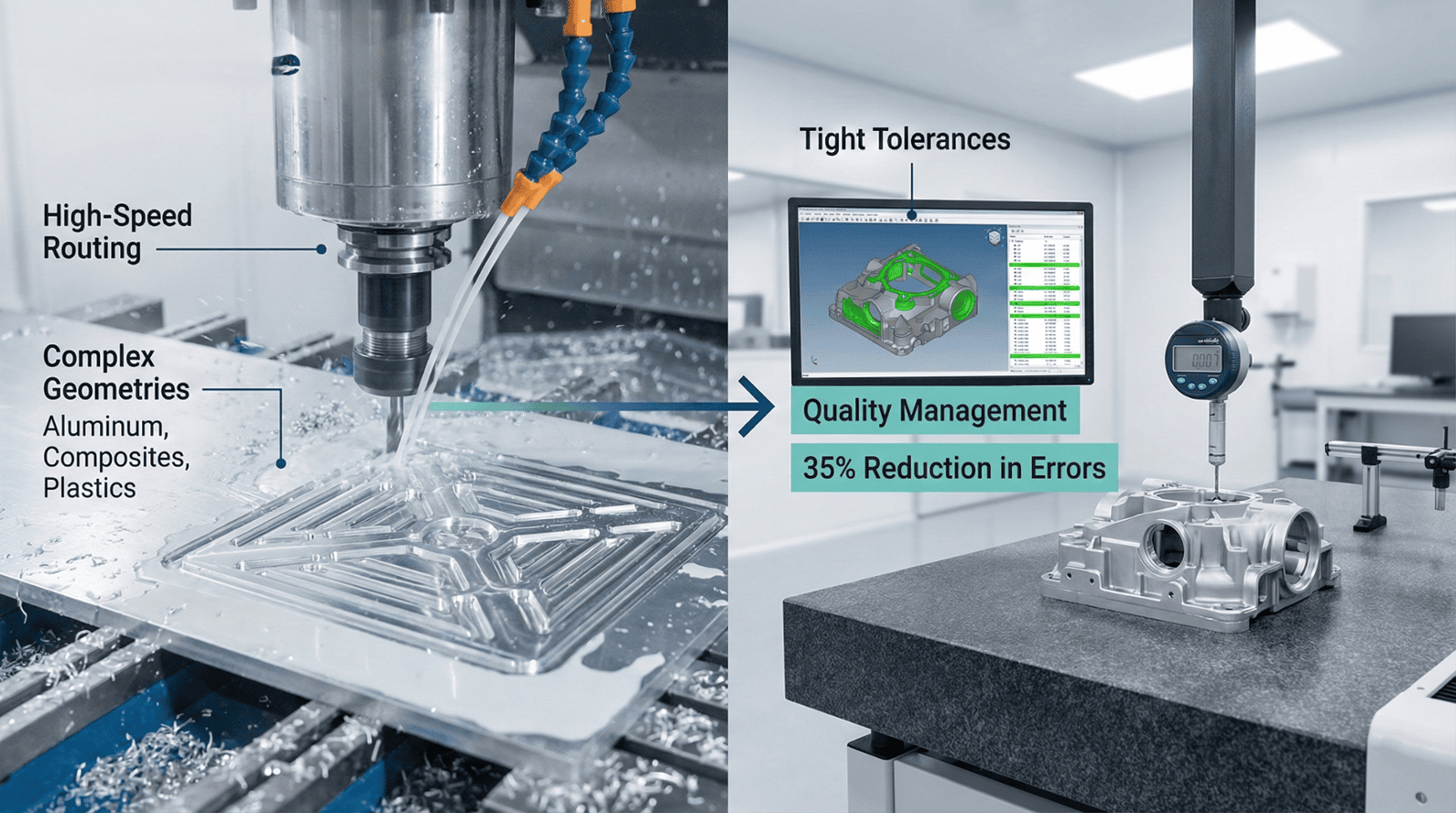

CNC router machining involves computer-controlled cutting tools that precisely shape raw materials into complex geometries. It differs from generic milling or turning services by offering high-speed routing, advanced toolpaths, and scalability for diverse materials, including aluminum, composites, and plastics. In OEM manufacturing, these capabilities are essential for producing structural parts, housings, fixtures, and functional components that must maintain tight tolerances.

For buyers, a supplier’s CNC router machining expertise determines whether your machined parts will function as intended when assembled into higher-level systems. It affects product quality, regulatory compliance, and warranty exposure long before parts reach assembly lines or end customers.

Understanding Supplier Capabilities Beyond the Quote

When evaluating CNC router machining suppliers, buyers should look beyond cost and lead time. Understanding a supplier’s capability includes reviewing their machine park, inspection systems, and quality management processes. A supplier should be equipped to handle the specific tolerance and surface finish requirements of your parts, as well as dynamic production volumes.

For example, a medical device company that selected a supplier with advanced multi-axis CNC and sterile manufacturing environments reported a 35% reduction in machining errors and faster regulatory approval. This improvement was directly tied to the supplier’s capability to consistently meet stringent tolerances as part of its quality process.

Evaluating Quality Systems and Supplier Compliance

An essential part of vendor vetting is confirming that suppliers follow recognized quality standards. Certifications such as ISO 9001, ISO 13485 (for medical devices), and AS9100 (for aerospace) demonstrate that a supplier maintains documented processes and traceability, which reduces variability in CNC router machining outcomes.

Suppliers should be able to provide relevant certification documentation and explain how these systems influence their machining processes. When quality systems are weak or undocumented, buyers risk receiving parts with inconsistent dimensions, poor surface finishes, or hidden defects—all of which can lead to costly rework or warranty claims.

In another case, a food processing OEM had to recall products when sealing rings from a CNC supplier failed regulatory standards due to inadequate compliance controls. The supplier’s lack of adherence to required industry standards underscored how critical compliance verification is in supplier selection.

Assessing Vendor Vetting Through Real Performance Metrics

Supplier compliance alone is not enough. Buyers must also assess supplier performance over time. A strong supplier scorecard can reveal trends in quality, delivery reliability, and responsiveness. Metrics such as defect rates, on-time delivery percentage, and responsiveness to technical concerns reflect a supplier’s operational discipline and commitment to continuous improvement.

Buyers should require detailed inspection reports and historical performance data during routine evaluations. Transparency in these areas indicates a supplier’s reliability and accountability. A supplier scorecard with consistently high marks not only signals competence but also enables buyers to benchmark potential partners effectively.

The Importance of Technical Collaboration and Communication

A supplier should not simply execute machining programs; they should act as a technical partner. Effective communication on design for manufacturability (DFM) can prevent avoidable issues early in the engineering cycle. For instance, suppliers with stronger DFM expertise can suggest improvements that reduce machining time, minimize tool changes, and improve part quality.

Buyers should observe how suppliers handle engineering questions before awarding work. A supplier that asks detailed, application-specific questions demonstrates a proactive approach rather than a transactional mindset.

Case Study: Overcoming CNC Routing Challenges

Case Study: Aerospace Production Run Recovery

An aerospace company experienced a costly setback when its original CNC routing supplier delivered parts with significant tolerance deviations, resulting in a scrapped production run and a $50,000 material loss. Seeking a better partner, the buyer switched to a supplier with robust CNC router machining processes and demonstrated inspection rigor. The new partner’s focus on precise toolpath validation and in-process inspection prevented recurrence of tolerance issues, restored production timelines, and protected subsequent assembly quality.

This case illustrates why OEM buyers must insist on documented inspection protocols, process transparency, and clear communication during CNC router machining. The right supplier can turn a high-risk situation into a controlled, repeatable process.

Tailoring Supplier Selection to OEM Manufacturing Needs

Different industries demand different machining rigor. For example, aerospace components typically require tighter tolerances and stricter traceability compared to industrial parts. Medical devices often require compliance with hygiene standards and biocompatibility regulations. Buyers must align supplier vetting criteria with industry expectations to avoid misalignment between part requirements and supplier capabilities.

Industry intelligence and past experience with similar parts also play a role. A supplier with a history of machining parts for your specific sector is more likely to anticipate challenges and propose solutions that work in real production settings.

Red Flags in Supplier Vetting That Buyers Should Avoid

During vendor vetting, buyers should be wary of:

Suppliers unable to provide current quality certifications or inspection data

Lack of transparency in machining processes and historical performance

Communication delays or vague responses to technical questions

No willingness to collaborate on DFM or continuous improvement

These red flags often signal deeper operational issues that can lead to inconsistent machined parts, missed delivery windows, or hidden costs.

Building Long-Term Supplier Relationships for Better Outcomes

Selecting the right CNC router machining supplier is not a one-time decision. Buyers should establish long-term performance agreements that include periodic audits, shared scorecards, and continuous improvement goals. Regular performance reviews strengthen accountability and encourage suppliers to invest in quality systems that benefit both parties.

Strategic Supplier Selection Protects Quality and Supply Chain Resilience

Choosing the right CNC router machining supplier is a strategic buyer responsibility. It influences product quality, OEM manufacturing reliability, failure rates, and time to market. Buyers who integrate structured vendor vetting, enforce supplier compliance, and track performance through supplier scorecards reduce risks and build resilient supply chains.

Supplier selection must prioritize capability, compliance, and communication—not just cost. When done correctly, it creates stable partnerships that support both innovation and production excellence.

Strengthen Your CNC Machining Supplier Strategy

If you’re responsible for sourcing precision machined parts and want to elevate your CNC router machining supplier selection process, now is the time to act. Adopt comprehensive vetting practices, enforce compliance standards, and measure performance with robust scorecards. Strengthen your supply chain today and drive better quality, delivery, and long-term value from your precision machining partnerships.

Frequently Asked Questions

1. Why do OEMs prefer nonferrous metals for critical machined parts?

OEMs prefer nonferrous metals because they offer corrosion resistance, lower weight, and better thermal or electrical conductivity compared to ferrous materials. These properties improve part performance, reduce long-term maintenance risk, and support lightweighting initiatives in aerospace, electronics, and transportation programs. For suppliers, this also means faster machining and more predictable production outcomes.

2. What machining challenges should suppliers expect when working with nonferrous metals?

While nonferrous metals are generally easier to machine, they present unique challenges such as built-up edge, chip control issues, and surface finish sensitivity. Aluminum, copper, and titanium each require different tooling, feeds, and speeds. Suppliers that fail to adjust CNC programming and tooling strategies risk inconsistent machined parts and rejected OEM inspections.

3. How does anodizing affect tolerances on nonferrous machined parts?

Anodizing adds a controlled oxide layer that can change part dimensions, especially on tight-tolerance features. Suppliers must account for this during machining by adjusting tolerances and documenting the process in their control plans. OEMs expect suppliers to demonstrate that anodized metal parts still meet functional and dimensional requirements after finishing.

4. Why is the PPAP approval process critical for nonferrous metal components?

The PPAP approval process validates that a supplier’s nonferrous machining, finishing, and inspection processes are stable under real production conditions. OEMs use PPAP to confirm material consistency, CNC process control, and repeatability before approving full-scale production. Weak PPAP submissions often signal higher risk and can delay or block supplier approval.