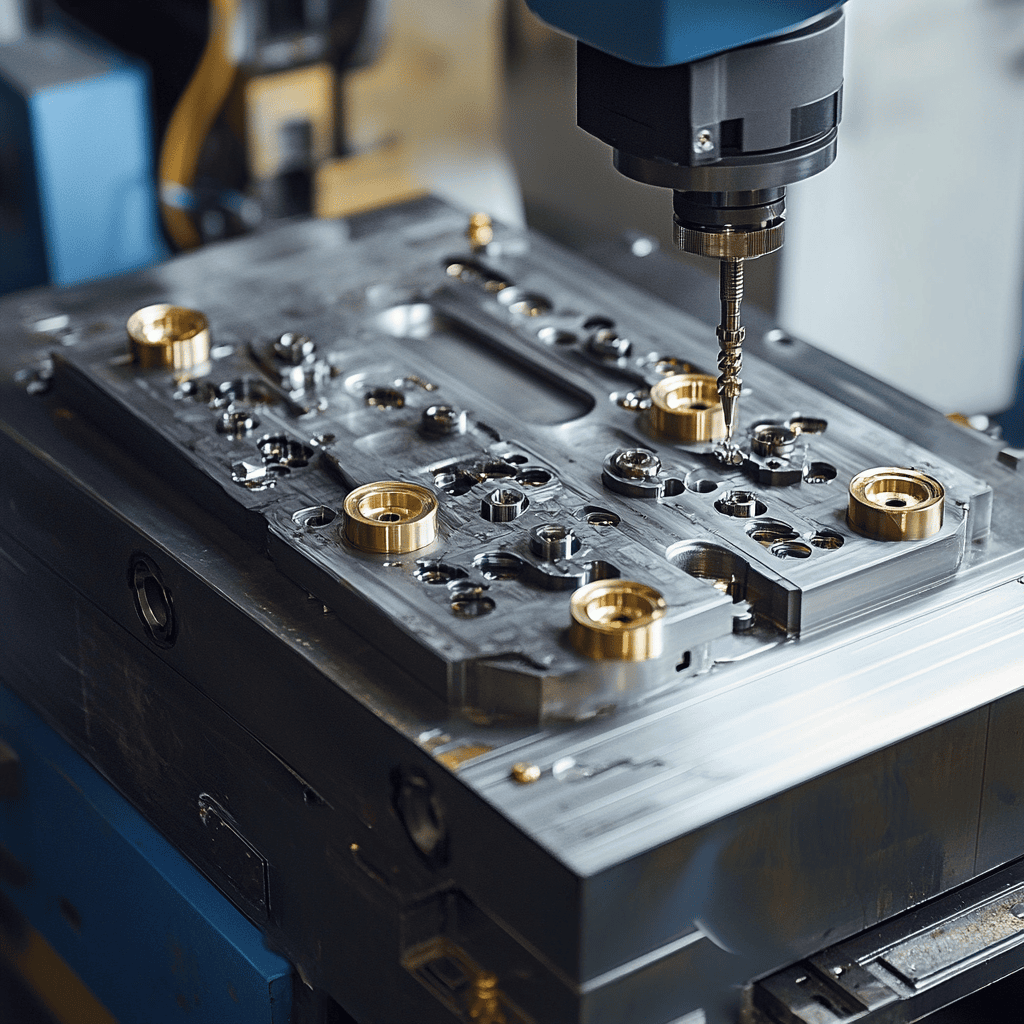

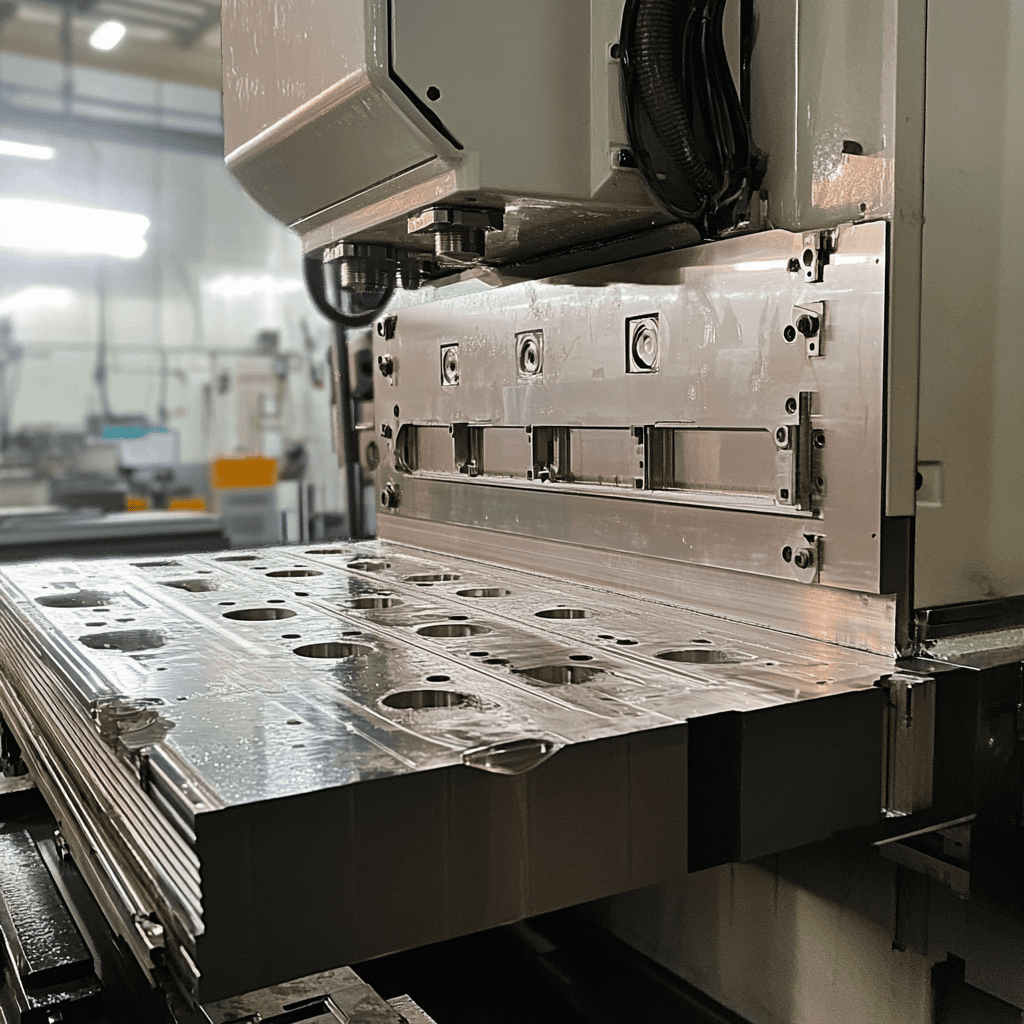

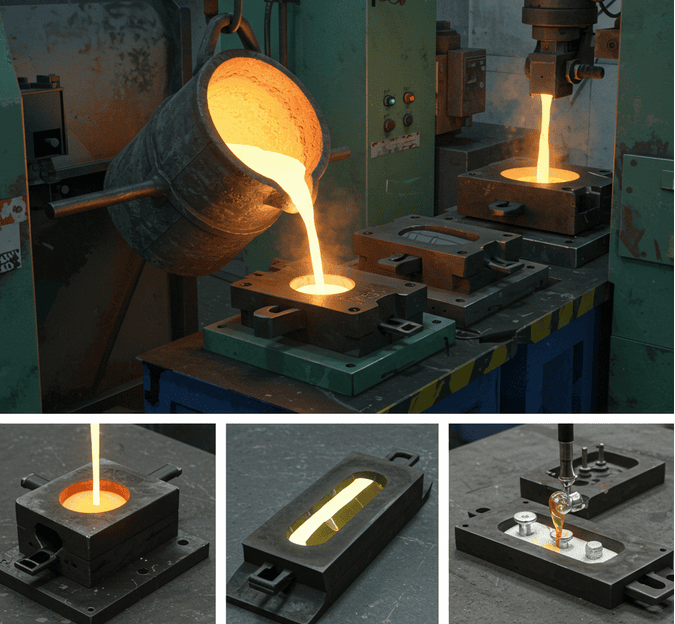

At Trustbridge, our Design for Manufacturability (DFM) services help you avoid expensive surprises and unnecessary delays by optimizing your part designs for the real-world constraints of production before a single tool is cut or part is made. Whether you're prototyping a new product, preparing for injection molding, or trying to reduce cost in an existing design, our engineers provide detailed, actionable feedback to align your design intent with the realities of machining, molding, casting, printing, and more.

We’ve supported hundreds of successful product launches across industries and we’ve seen what works, what fails, and what costs you time and money. Let us bring that insight to your design process.

Design for Manufacturability (DFM) Services: Optimizing Product Design For Efficient Manufacturing

Our DFM Services at a Glance

Why Trustbridge for DFM?

Cross-Process Expertise: Our team has worked across machining, molding, casting, and printing so we know how to design for all of them.

Connected to the Factory Floor: Our feedback reflects real-world vendor constraints because we also manage the suppliers.

Clear, Actionable Feedback: We don’t just say “this might be a problem” we show you what to change and why.

Outcome-Focused: Our goal isn’t just a cleaner CAD model it’s parts that run right the first time, at the right cost.

One Partner from Design to Production: Once your part is optimized, we can quote, prototype, and scale it through our manufacturing network.

Don’t Wait to Find Out What Went Wrong. Design It Right the First Time.

Our DFM reviews start at the earliest stages of development and can save you weeks and thousands of dollars down the line.

Explore Related Services

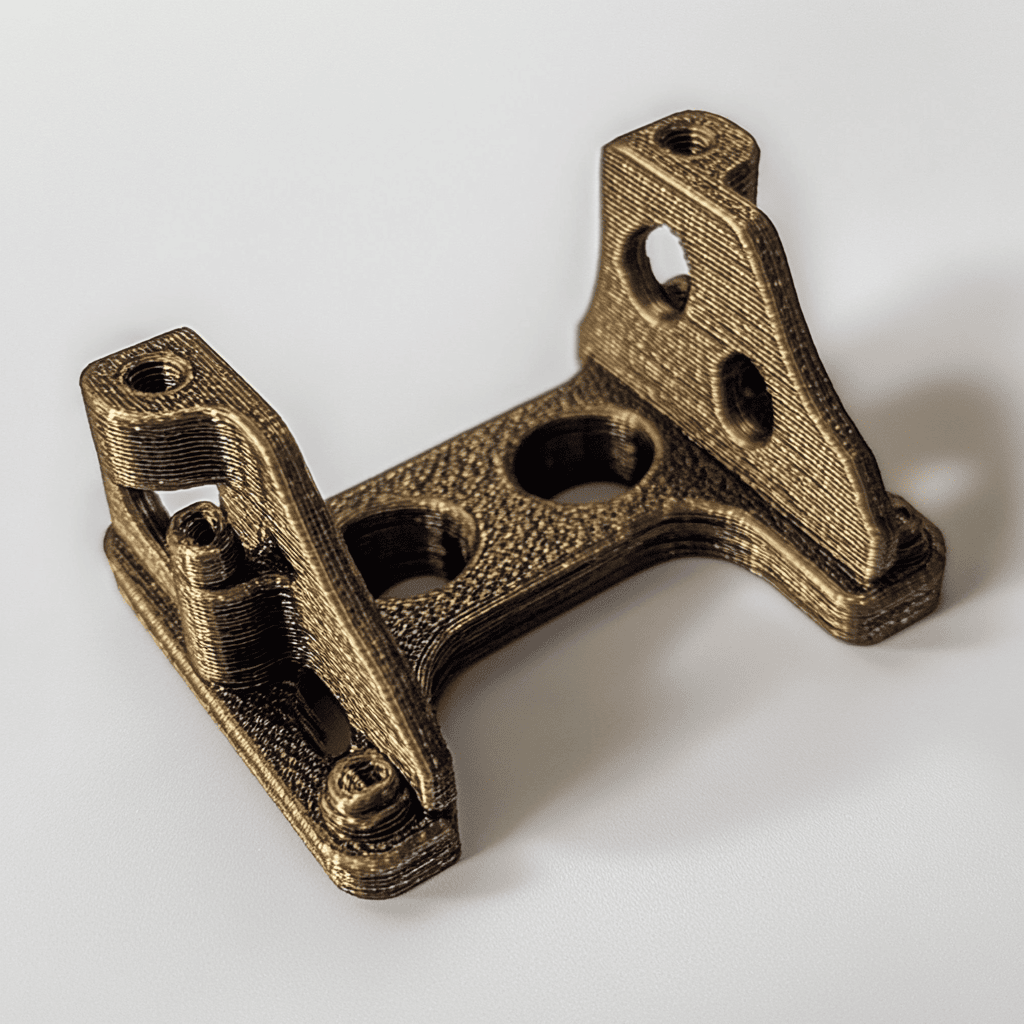

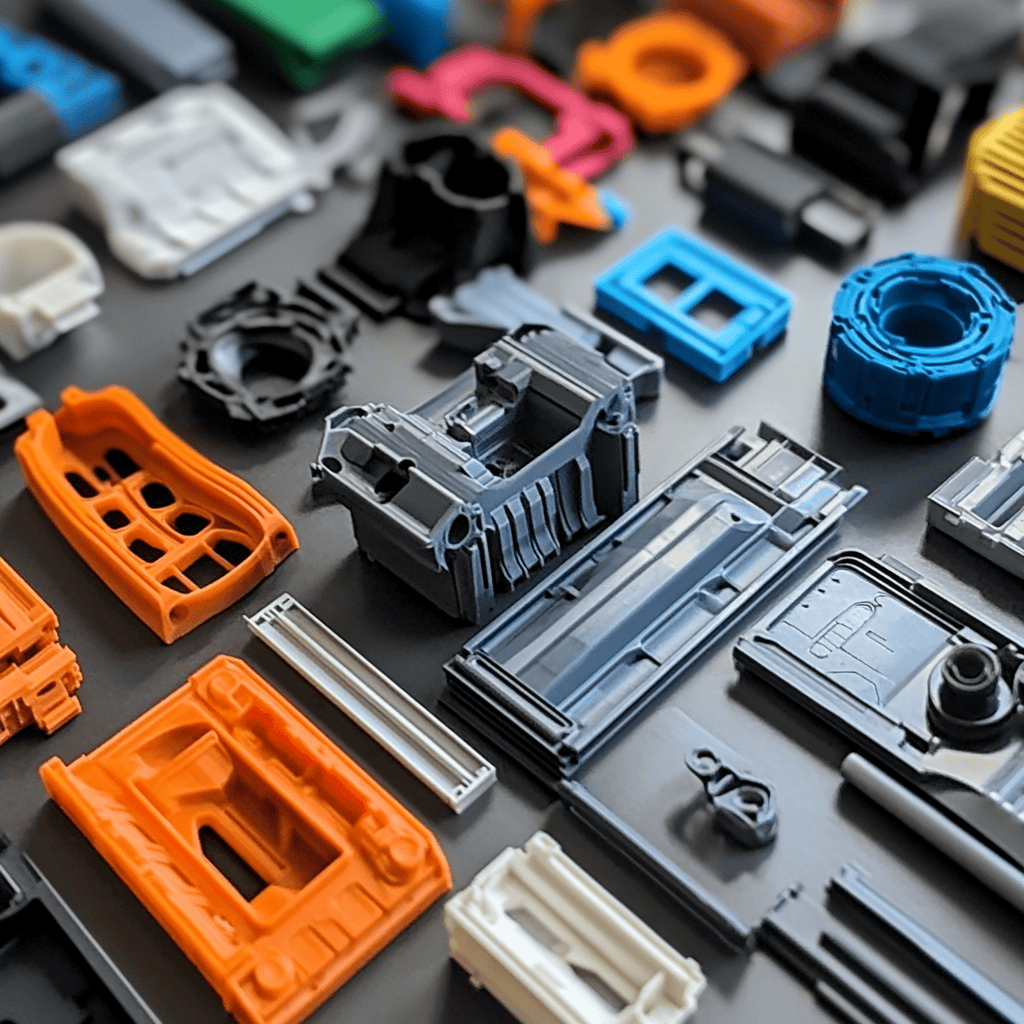

3D Printing

Rapid, cost-effective prototyping and low-volume production with complex geometries and minimal tooling.

Sheet Metal Fabrication

Cut, bend, and assemble custom enclosures, brackets, and panels — scalable from prototypes to full production runs.

Injection Molding

High-volume plastic part production with consistent quality, fast cycle times, and low per-unit cost once tooled.