Strategic Prototyping & Material Selection for Optimal Product Development

At Trustbridge, we help teams prototype with purpose. Our Prototyping Strategy & Material Guidance services ensure you select the right process and material for each phase of development — balancing speed, cost, and performance at every step. Whether you're validating a concept, pitching to investors, testing form and fit, or preparing for regulatory approval, we match your goals with the best prototyping methods available. With deep cross-process knowledge and access to our global manufacturing network, we go beyond just building your prototype — we help you prototype in a way that sets you up for production success.

Our Prototyping Strategy & Material Guidance Services at a Glance

Need a Prototype — or a Smarter Plan for Building One?

Explore Related Services

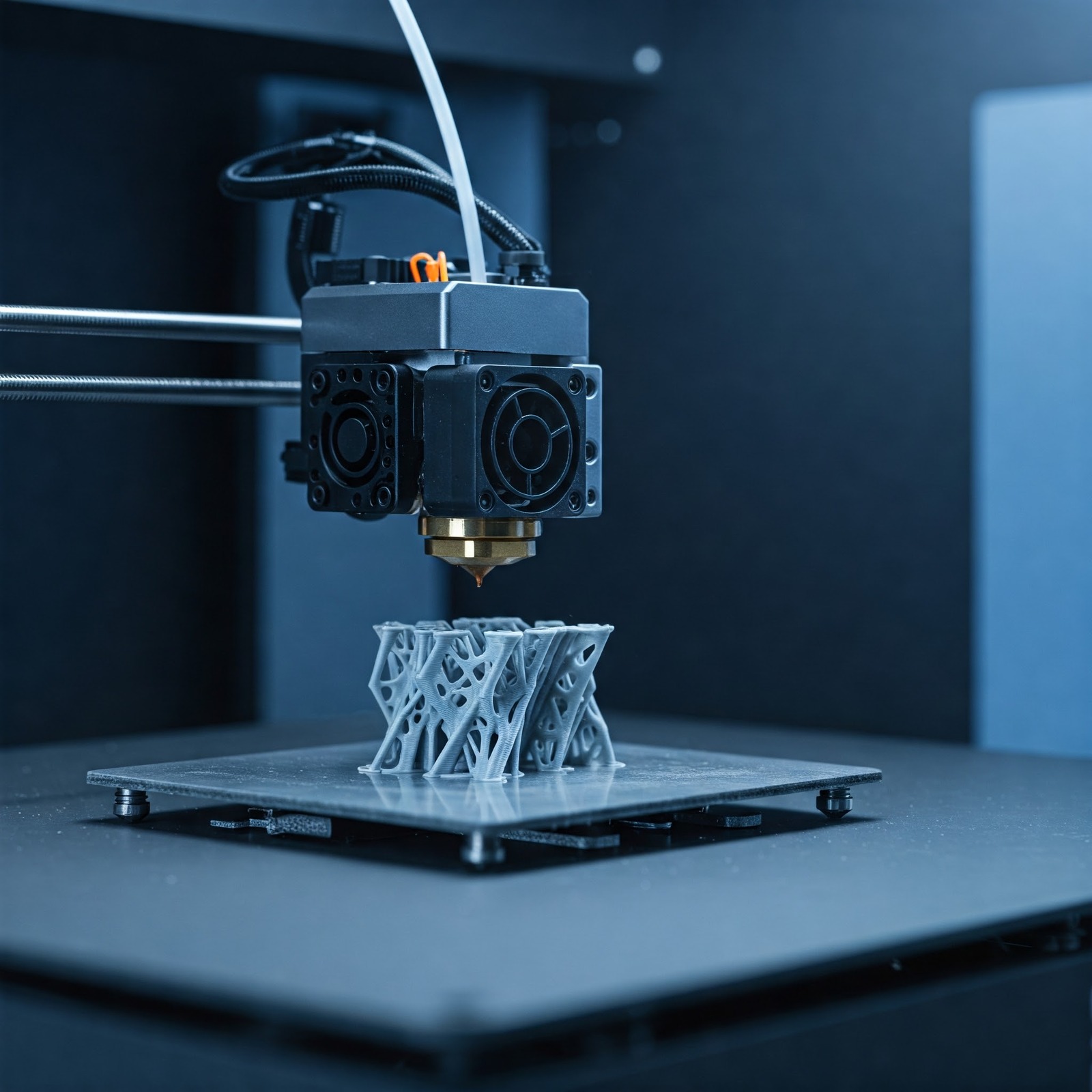

3D Printing

Rapid, cost-effective prototyping and low-volume production with complex geometries and minimal tooling.

Sheet Metal Fabrication

Cut, bend, and assemble custom enclosures, brackets, and panels — scalable from prototypes to full production runs.

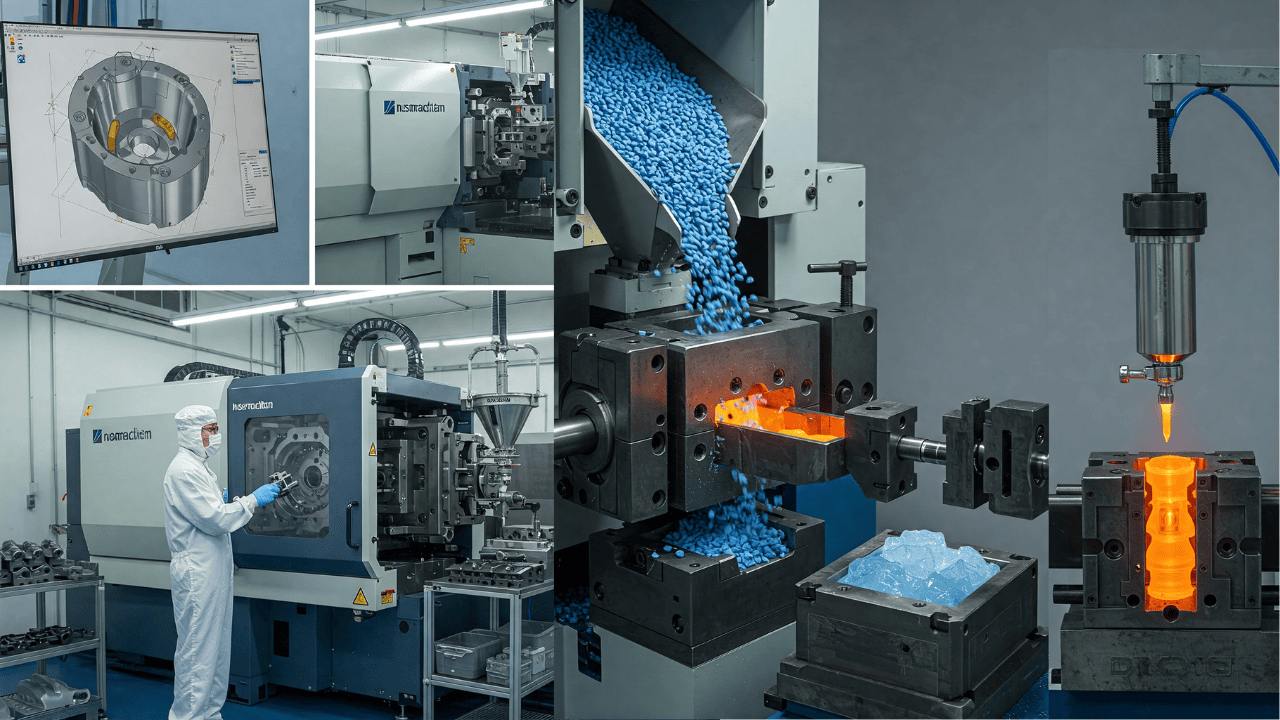

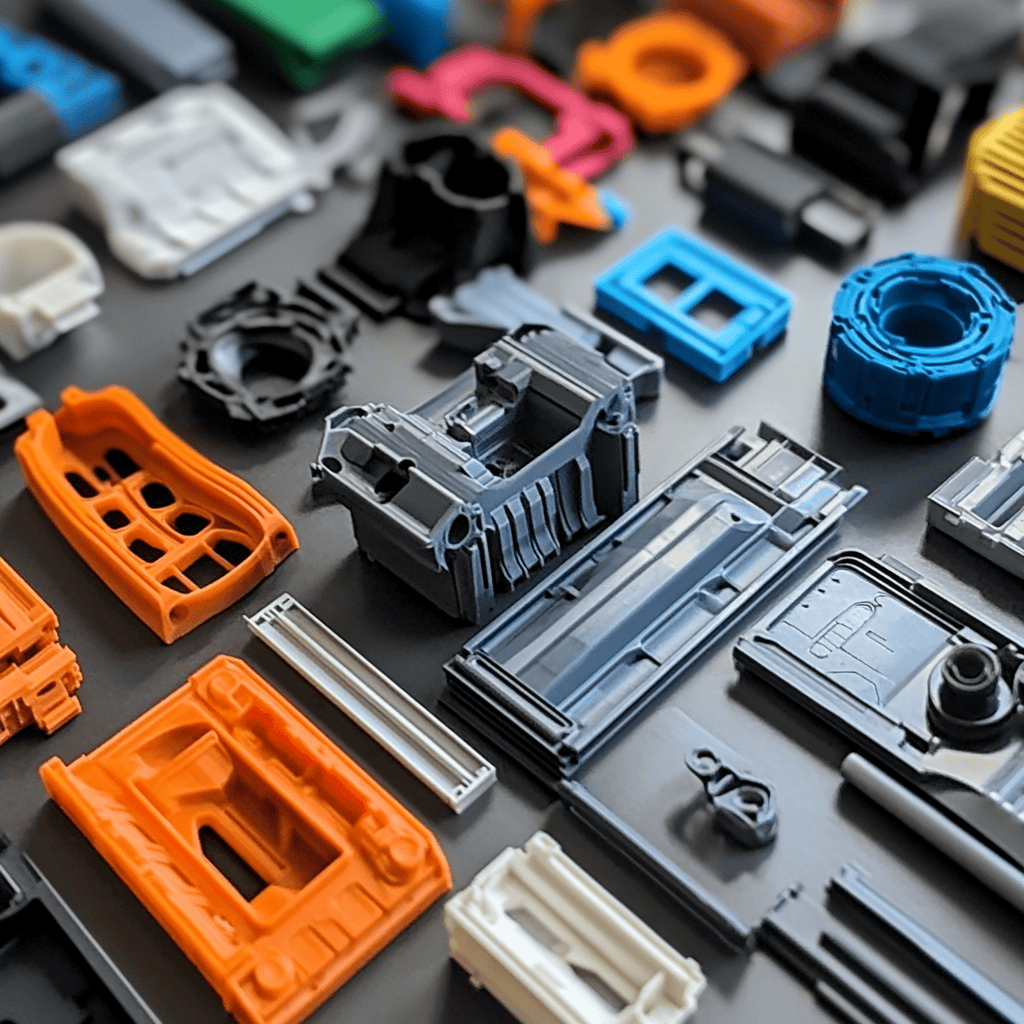

Injection Molding

High-volume plastic part production with consistent quality, fast cycle times, and low per-unit cost once tooled.