KPI Driven Procurement: How to Track Supplier Performance Effectively

In today’s manufacturing supply chains, buyers are under increasing pressure to reduce risk, maintain consistent quality, and hit tight production timelines. The challenge isn’t just finding suppliers it’s managing them with the right structure and visibility. That’s where strong procurement KPIs and measurable systems come in. When buyers can track performance consistently, they make faster decisions, avoid costly surprises, and prevent quality issues long before they reach production.

The most efficient procurement teams don’t rely on intuition. They depend on data specifically quality metrics, delivery accuracy, cost stability, and compliance signals that help them evaluate supplier performance objectively. This shift toward more structured oversight is why tools such as a supplier scorecard, risk-assessment models, and qualification checklists are becoming core parts of modern sourcing strategies.

Why Tracking Supplier Performance Matters More Than Ever

Most supplier issues don’t blow up overnight they build slowly. A missing COA here, a late email there, a small deviation that “shouldn’t matter.” Before you know it, samples fail FAI, timelines slip, and the supplier claims they “never received the updated drawing.”

This is exactly why clear procurement KPIs matter. They help buyers spot misalignment early, before it becomes a production delay. With the right KPIs, buyers can see when a supplier is slipping communication slowdowns, rising defects, late documentation, or capability gaps.

Teams that adopt structured measurement see real benefits:

- Fewer escalations

- Shorter PPAP and FAI cycles

Better documentation discipline

Example: One published case study showed that after implementing a supplier performance tracking program, a manufacturing company significantly improved on-time delivery and reduced defect rates. By making expectations measurable instead of relying on assumptions, suppliers adjusted their internal processes and communication—leading to more predictable production outcomes.

Using a Supplier Scorecard for Real Accountability

A supplier scorecard gives buyers real accountability. Instead of relying on mixed feedback from engineering, QC, and purchasing, the scorecard creates one shared version of the truth. Suppliers know they’re being measured, which means they respond faster, follow instructions more carefully, and control their processes more tightly.

The biggest benefit isn’t the score—it’s the trend. A supplier may deliver good parts today, but if documentation mistakes or slow responses are increasing, that’s a clear sign of deeper issues. Scorecards help buyers spot this months earlier, long before it becomes a quality problem.

Strengthening Supplier Risk Management Before Problems Escalate

A strong supplier risk management system helps buyers catch problems before they become emergencies. Risk isn’t only about bad parts—it’s about capacity gaps, inconsistent communication, unstable processes, or suppliers who haven’t handled similar tolerances before.

High-performing teams review risk proactively, not after a failure. They look at process flow, NC history, response times, and whether the supplier can provide reliable traceability. When early risk indicators show up, buyers can re-route work, build a backup option, or require corrective action before production is impacted.

Example: In more advanced supply-chain frameworks, companies are beginning to use data-driven models to predict supplier financial risk before it affects production. A 2025 research study showed how analytics-based risk scoring can help buyers anticipate credit instability, late-payment vulnerabilities, and operational disruptions long before they appear in quality or delivery data.

How Digital Procurement Tools Improve Visibility and Speed

Modern digital procurement tools make it easier for buyers to stay organized and avoid costly miscommunication. These tools centralize files, track documentation accuracy, and keep a timestamped record of every supplier message—no more searching through email threads or losing the latest drawing.

They also provide real-time dashboards, so buyers can immediately see who’s meeting expectations and who’s trending downward. This helps teams shift from reactive firefighting to proactive supplier planning.

Example: When a global industrial manufacturer digitized its sourcing process with a procurement platform, the team stopped chasing versions of the latest drawing and started monitoring live supplier metrics instead. The digital system automated document control logged supplier communication, and surfaced KPI trends on dashboards—so buyers could spot a performance dip and act before parts reached the line.

Trustbridge Tip: Clear drawings, defined requirements, and strong buyer–supplier alignment are essential for predictable production, but many quality or delivery issues start much earlier in the process. Shops often struggle with deeper operational gaps such as capacity bottlenecks, incomplete documentation habits, weak process control, and inconsistent repeatability. To understand these hidden challenges and how leading manufacturers overcome them, explore our guide on improving alignment and production accuracy: How Buyers Can Improve Supplier Alignment to Ensure Accurate, Repeatable Production.

Ensuring Supplier Compliance Across Quality and Documentation

Every buyer knows the frustration of a supplier who says they’ll follow requirements but doesn’t actually do it. Strong supplier compliance systems fix this by defining expectations clearly and verifying them consistently—not just at the start, but throughout the relationship.

Compliance includes much more than certificates. It’s about process discipline, documentation accuracy, and consistent repeatability. When buyers track compliance regularly, they get fewer surprises and more control over production.

Example: A recent industry analysis found that organizations with strong supplier compliance systems saw fewer documentation errors, better audit preparedness, and improved traceability. Clear compliance expectations helped suppliers maintain tighter process control, reducing the likelihood of quality escapes.

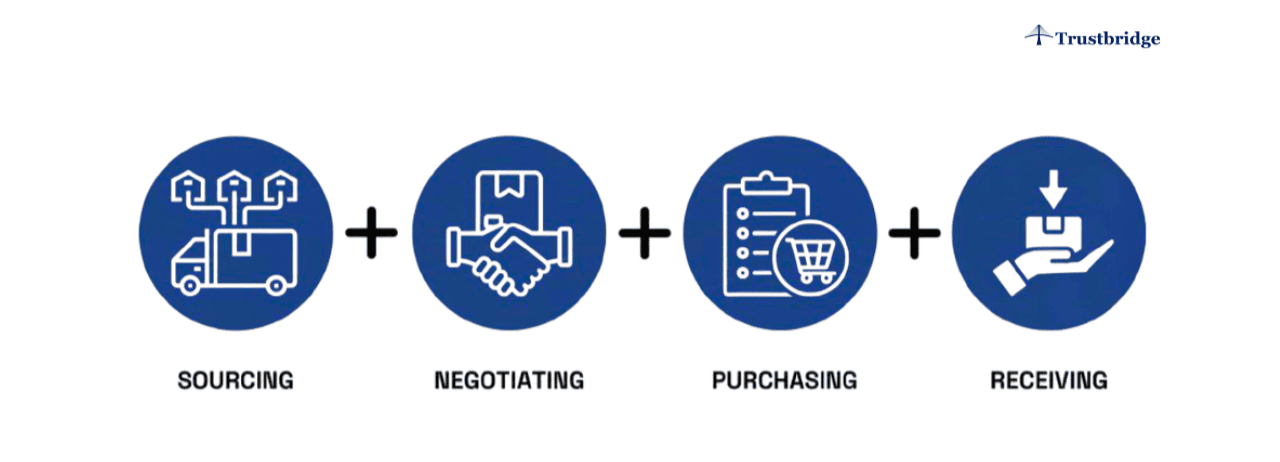

Why Every Buyer Needs a Vendor Qualification Checklist

A vendor qualification checklist gives procurement teams a structured way to evaluate suppliers, no assumptions, no guesswork. It forces buyers to look beyond price and confirm capability, process maturity, documentation discipline, and quality control systems.

Teams that use a checklist avoid onboarding suppliers who can’t scale, lack critical equipment, or struggle with inspection requirements. It also makes vendor comparison much easier and much fairer.

Example: Companies that formalize onboarding with a vendor qualification checklist reduce surprises later. One procurement guide shows how a structured qualification flow verifying capacity, certifications, inspection capabilities, and traceability—shortens approval time and prevents buyers from awarding work to suppliers who can’t scale or meet inspection standards.

Conclusion

Strong supplier management is now a strategic advantage. Buyers who track the right procurement KPIs get clearer visibility, faster decision-making, and fewer production surprises. With tools like a supplier scorecard, structured risk management, modern digital systems, stronger compliance tracking, and a reliable vendor qualification checklist, procurement teams reduce uncertainty and build a more predictable supply chain.

Trustbridge supports buyers by providing the tools, insights, and expertise needed to execute strategic quote comparisons at scale. Ready to transform your sourcing decisions? Visit Trustbridge.pro to explore resources, case studies, and solutions designed to help procurement professionals make smarter, more confident buying decisions.

Frequently Asked Questions

1) What are the most important KPIs for tracking supplier performance?

The core KPIs buyers rely on include quality defect rates, on-time delivery, documentation accuracy, responsiveness, and cost stability. These KPIs give buyers a clear picture of whether a supplier is improving, slipping, or becoming a risk. Tracking them consistently helps prevent delays and keeps production predictable.

2) How does a supplier scorecard improve accountability?

A supplier scorecard creates a single, objective record of performance. Instead of scattered feedback, it shows measurable trends in quality, delivery, and communication. When suppliers know they’re being evaluated transparently, they respond faster, follow requirements more carefully, and maintain tighter process discipline.

3) Why is risk management necessary even for suppliers who deliver good parts today?

Good parts today don’t guarantee stability tomorrow. Early risk signals—slow responses, capacity gaps, inconsistent documentation, or lack of traceability—often show up long before a quality failure. Proactive risk reviews help buyers catch these issues early and take action before production is disrupted.