The Buyer’s Guide to Early Quality Alignment: Requirements That Protect Your Production

Anyone who has ever sourced parts from a new supplier knows this: quality problems rarely happen on the factory floor, they happen long before production even starts. Buyers often feel the impact first. They may experience delayed samples, unexpected rework, or parts that don’t match the drawing, all because suppliers interpreted requirements differently. When drawings are unclear or expectations are not aligned, suppliers fill in the blanks themselves and that’s usually when costly issues appear.

Setting clear supplier quality requirements early is one of the strongest levers buyers have to protect cost, lead time, and supply-chain stability. A well-defined First Article Inspection (FAI) also gives buyers proof that the supplier fully understands the part before any volume decisions are made.

This guide breaks down the quality expectations buyers should enforce from Day One and how those early decisions shape your final output.

Why Supplier Quality Requirements Matter to Buyers

Most quality issues don’t come from bad machining they come from supplier assumptions that buyers never intended. If a drawing or requirement leaves room for interpretation, the supplier will choose the option that best fits their process, not yours.

Clear, complete requirements remove that ambiguity. They keep control in the buyer’s hands, reduce unnecessary sample rounds, and prevent surprises that increase cost or push back timelines. For buyers managing tight schedules or high-spec parts, this level of clarity becomes a strategic advantage not just a quality step.

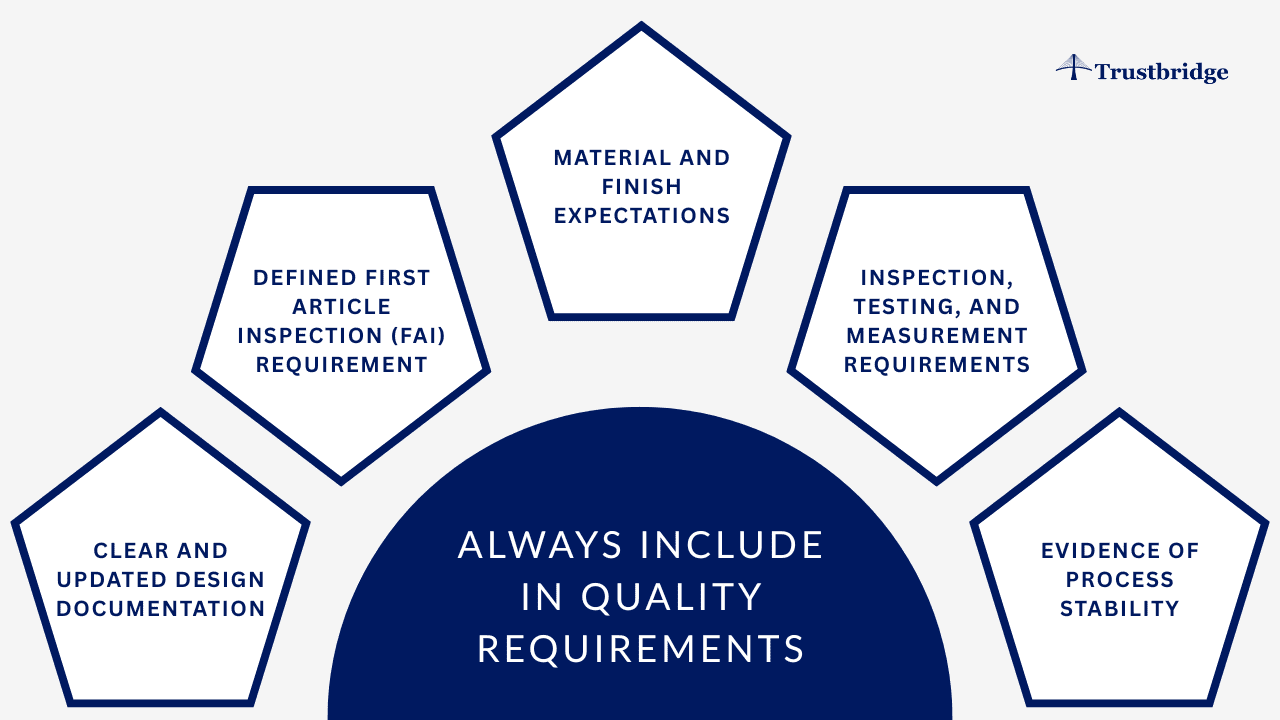

What Buyers Should Always Include in Their Quality Requirements

Clear and Updated Design Documentation

Suppliers work with whatever you give them. Unless your drawing is finalized and free of old notes, the supplier will construct it with every mistake intact. That’s why your drawing should clearly mark critical dimensions, tolerances, surface requirements, and any areas where function is sensitive.

A clean, up-to-date drawing also becomes the foundation for your supplier’s inspection report, which means fewer surprises when the first article arrives.

A Defined First Article Inspection (FAI) Requirement

FAI is essentially your insurance policy as a buyer. It verifies that the supplier can produce your part the way it was designed not the way they interpreted it. But FAI only works when it’s spelled out clearly.

Buyers should specify what the supplier needs to measure, how many samples are required, and what must be included in the FAI report. When these expectations are clear, FAI becomes a powerful tool for preventing scale-up problems.

Example - Process Stability (Unitek Case Study)

In a real-world supplier-development case study by Unitek, buyers recognized that a single “golden part” inspection wasn’t enough. Instead, they required FAI approval across multiple production lots to confirm that the supplier’s manufacturing process was truly stable. By asking for repeatable results over several batches, the buyer gained confidence that quality would remain consistent when they scaled production. You can read more about how they implemented this strategy in Unitek’s public case study.

Material and Finish Expectations

It’s common for suppliers to choose “equivalent” materials unless the buyer defines exactly what is required. From a buyer’s standpoint, this introduces major downstream risk performance changes, compliance failures, warranty issues, and expensive redesigns.

To prevent this, buyers should lock in material grade, heat treatment, coating, and finish before samples begin. Clear specifications ensure the supplier cannot make cost-driven substitutions that compromise part performance.

Inspection, Testing, and Measurement Requirements

Don’t wait until after the first shipment to clarify testing expectations. Without buyer direction, suppliers may rely on minimal in-house checks that don’t match your tolerances or functional needs. When buyers specify required inspections upfront Coordinate Measuring Machine (CMM) checks, performance validation, visual criteria, or test loads they ensure the supplier’s process aligns with what the part is expected to do in the field.

Evidence of Process Stability

Even if a supplier makes one perfect part, it doesn’t mean they can repeat it hundreds of times. That’s why buyers should ask for documented evidence of process stability not just a single successful sample. In a case study by Unitek, the buyer required FAI approval not just for one “golden part,” but across multiple production lots to ensure genuine consistency. This kind of repeated verification pushes suppliers to stabilize their manufacturing process before full-scale production.

Trustbridge Tip: Clear drawings, defined requirements, and strong buyer–supplier alignment is essential, but shops also face deeper operational challenges that affect delivery, quality, and repeatability. From capacity constraints to inconsistent processes, these issues can slow production and hurt customer confidence. To understand the most common challenges manufacturers face and how leading shops overcome them explore our guide on strengthening custom manufacturing performance: Top Challenges in Custom Manufacturing and How to Overcome Them.

How Buyers Can Strengthen Supplier Alignment

Provide 3D Models Alongside Your 2D Drawing

A 2D drawing shows what’s important, but a 3D model shows how everything fits. Sharing both eliminates confusion, especially in parts with complex geometry. Suppliers can plan tooling better, visualize features more accurately, and reduce the risk of misinterpretation.

Highlight the Features That Matter Most

Not every dimension is created equal. Some affect function, some affect safety, and others relate to assembly. When you tell your supplier which features cannot fail, they can build their inspection plan around them, reducing the chance of receiving parts that meet the drawing but not your product’s real-world needs.

Explain Your Production Intent Early

Buyers often focus on the immediate need samples or small batches but don’t mention future volume. Suppliers need this visibility to decide tooling, equipment, and inspection capacity. Being transparent about expected volume helps your supplier make smarter production decisions.

Establish a Shared Quality Agreement

A quality agreement sounds formal, but it saves time and arguments later. It lays out how changes are approved, how defects should be reported, what inspection steps are mandatory, and how non-conformances will be handled. This creates clarity and reduces back-and-forth during production.

The Business Value for Buyers

When buyers set strong supplier quality requirements early, they aren’t just protecting part quality they’re protecting budgets, deadlines, and customer commitments. Clear requirements reduce scrap, prevent additional sample rounds, and eliminate the hidden communication loops that delay production.

Most importantly, buyers gain predictable performance from suppliers, strengthening long-term partnerships and reducing the risk of costly launch disruptions.

In short, your upfront investment in clarity pays for itself through smoother production, fewer delays, and better reliability.

Conclusion: Turning Quote Comparison into Strategic Advantage

Trustbridge supports buyers by providing the tools, insights, and expertise needed to execute strategic quote comparisons at scale. Ready to transform your sourcing decisions? Visit Trustbridge.pro to explore resources, case studies, and solutions designed to help procurement professionals make smarter, more confident buying decisions.

Frequently Asked Questions

1. Why do most supplier quality problems happen before production even starts?

Most quality issues occur upstream because suppliers often interpret unclear drawings, incomplete requirements, or missing specifications differently than the buyer intended. When expectations aren’t aligned early, suppliers fill in the gaps using their internal standards, which may not match your needs. Early clarification prevents misinterpretation and reduces rework.

2. Is a First Article Inspection (FAI) really necessary for every new supplier or part?

Yes. FAI is one of the most effective ways to confirm that a supplier fully understands your design, tolerances, and functional requirements before scaling production. Without a defined FAI process, buyers risk discovering issues only after shipment—when fixes are more costly and time-consuming.

3. How can buyers make sure a supplier uses the correct materials and finishes?

Buyers must explicitly specify the required material grade, coatings, heat treatments, and surface finishes. If these details are left open, suppliers may choose cost-driven alternatives they consider “equivalent.” Clear material specifications ensure performance, compliance, and consistency.

4. What can buyers do to ensure production is repeatable, not just a one-time success?

Ask suppliers for documented proof of process stability such as equipment certifications, calibration records, or capability data. One good sample doesn’t guarantee repeatability; verifying the supplier’s process reliability ensures they can deliver consistent quality across every batch, not just the first part.