10 Proven Ways CNC Machining Suppliers Can Improve Their RFQ Response Rate in 2025

For CNC machining suppliers, responding to RFQs efficiently has never been more critical. With procurement cycles shrinking and buyers expecting faster turnaround times, delays or errors in quotes can cost suppliers not just a sale, but long-term credibility. Many suppliers struggle with scattered data, manual workflows, and unclear internal processes, leading to missed opportunities and frustrated buyers. These inefficiencies don’t just slow response times they create ripple effects across operations. Suppliers risk over-quoting and losing price-sensitive opportunities, under-quoting and eroding profit margins, or providing inconsistent information that damages trust. Each delayed or inaccurate quote not only reduces the chance of winning the project but can also harm a supplier’s reputation in an industry where reliability matters most.

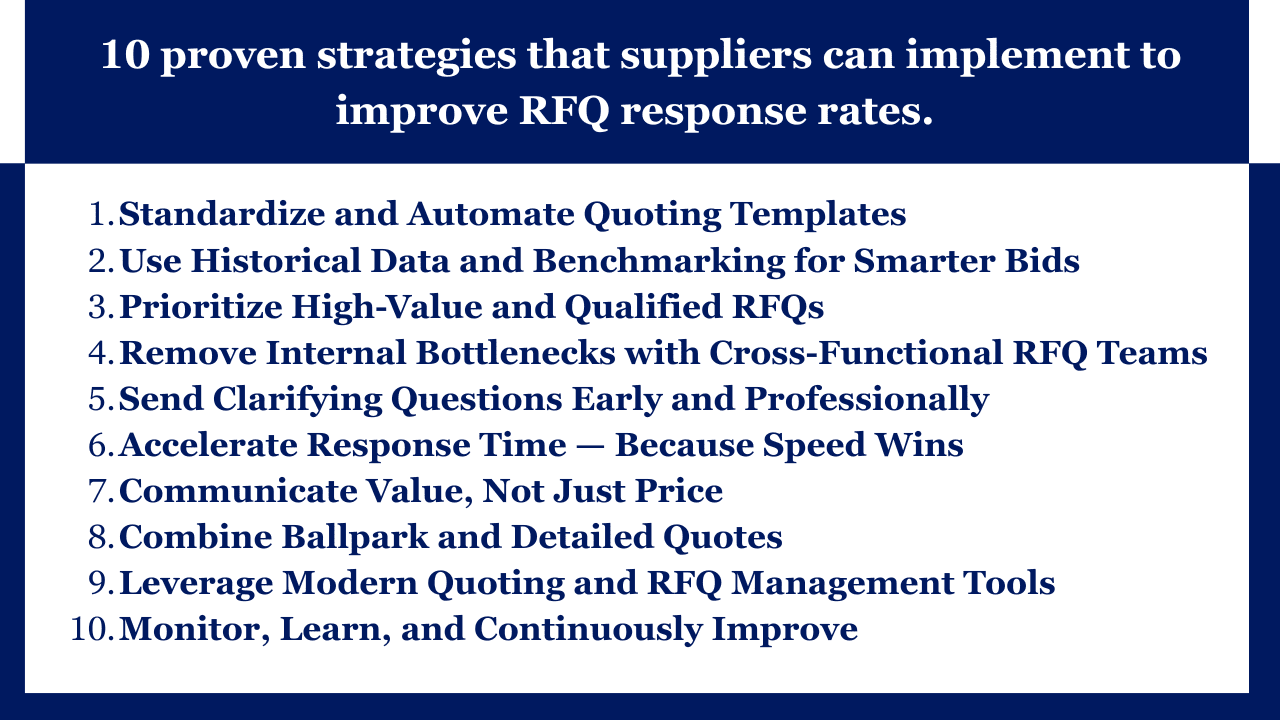

The solution lies in adopting a systematic, data-driven approach to RFQ management. By standardizing processes, leveraging historical data, and utilizing modern collaboration tools, CNC suppliers can streamline quoting workflows, improve accuracy, and respond faster. In 2025, mastering these strategies can turn RFQs from a bottleneck into a competitive advantage, helping suppliers win more business and strengthen relationships with buyers. Here are 10 proven strategies that suppliers can implement to improve RFQ response rates. If you want to know more about each strategy in detail, read below.

1. Standardize and Automate Quoting Templates

Most delays in RFQ response come from repetitive manual work. Every supplier knows how time-consuming it is to rebuild quote formats, recheck pricing formulas, or attach quality certificates each time. Standardized templates solve this by bringing order and repeatability to the process. A supplier with ready-to-use templates for different part types milling, turning, 5-axis, and assembly can save hours per quote.

Automation multiplies that efficiency. Using smart spreadsheets or quoting platforms, suppliers can pull live material rates, machine hour costs, and setup times automatically. Each quote looks clean, professional, and error-free, a subtle but powerful trust signal to buyers.

Deeper Insight:

Suppliers should build a “quote library” segmented by part type and complexity. Templates can include standard disclaimers, revision control, and pre-approved technical notes to eliminate back-and-forth. By versioning these templates, suppliers can also measure which quote styles or pricing layouts perform best in terms of buyer engagement. Over time, quoting becomes not just faster but strategically refined balancing speed with precision.

2. Use Historical Data and Benchmarking for Smarter Bids

Data is a CNC supplier’s hidden asset. Every quote and every job completed leaves behind valuable intelligence — what was quoted, what was accepted, and what was rejected. Suppliers who leverage that historical data can uncover patterns: which customers buy regularly, which part tolerances lead to higher scrap, and which material combinations yield better margins.

According to a study by the Center for Automotive Research, lack of structured internal data is one of the biggest barriers to efficient RFQ responses. This data gap often leads to inconsistent pricing and slower responses.

Deeper Insight:

Suppliers should maintain a simple cost intelligence database even a well-structured Excel or cloud sheet can do. Each past RFQ should be logged with parameters like complexity, tolerances, hours required, and profit margin. With 6–12 months of data, suppliers can benchmark realistic machining times and pricing ranges. When a new RFQ arrives, these insights shorten decision-making and prevent under- or over-quoting. The result: faster, more confident submissions.

Trustbridge Tip: Looking for a reliable CNC machining partner who can deliver precision, speed, and consistency? Trustbridge connects you with verified CNC suppliers, streamlines RFQs, and helps you source high-quality parts faster. Get Started Today

3. Prioritize High-Value and Qualified RFQs

Not every RFQ deserves attention and that’s a truth every supplier learns the hard way. Some buyers are price-shopping, others lack clear drawings, and a few may never place an order. In 2025, successful CNC suppliers will be prioritized. They define what “qualified” means volume potential, payment reliability, technical alignment, or industry segment and filter out distractions.

Deep Insights:

Implementing a lead-scoring matrix for RFQs can help. The supplier can rank inquiries on metrics like estimated annual demand, technical compatibility (machine fit), and margin expectation. For instance, an RFQ for 500 precision-turned aerospace parts with stable tolerance specs should outrank a single-piece prototype from an unverified buyer. This data-driven selection ensures effort is concentrated where it counts, improving both efficiency and morale in the quoting team.

RFQ Triage Process

- Acknowledge every incoming RFQ within hours.

- Classify based on technical complexity, buyer type, and part repeatability.

- Decline non-fit RFQs politely but professionally.

- Assign high-fit RFQs for immediate action.

This approach protects resources and keeps the supplier’s win rate healthy.

4. Remove Internal Bottlenecks with Cross-Functional RFQ Teams

One of the silent killers of RFQ efficiency is internal friction. When engineering, sales, and operations function in silos, even a simple quote can take days. Progressive CNC suppliers are building cross-functional RFQ response cells small teams empowered to make quick pricing, scheduling, and capability decisions.

Mapping the quoting workflow often reveals surprising inefficiencies: waiting for engineering validation, delayed cost inputs, or lack of real-time material pricing. Once identified, suppliers can set internal service-level agreements (SLAs) for example, “engineering review within four hours” or “pricing approval within one business day.”

Deeper Insight:

Digital collaboration tools such as centralized dashboards, quotation management systems, or ERP-integrated project boards bring instant visibility to every RFQ in progress. Each quote can move through clear, predefined stages such as received, under review, approved, and submitted, ensuring that no request gets buried in inboxes. According to a study by CostItRight, manufacturers that implemented quotation management software with automated approvals and real-time dashboards achieved up to a 40% reduction in quote cycle time. This demonstrates how greater visibility and workflow automation can make RFQ processes more agile, synchronized, and buyer responsive.

5. Send Clarifying Questions Early and Professionally

Too often, suppliers rush to submit quotes based on incomplete drawings or vague specs. The result? Wrong assumptions, missed costs, or re-quotes that frustrate buyers. The more strategic approach is to ask smart questions early within hours of receiving the RFQ.

Buyers appreciate suppliers who think critically. Sending a clarification list covering materials, finishes, tolerances, heat treatments, or packing demonstrates precision and care. It positions the supplier as a true partner, not a passive vendor.

Deeper Insight:

Suppliers can standardize this into a “RFQ clarification checklist.” Once an RFQ arrives, a pre-formatted email with key questions can go out automatically. This process reduces quote revisions and improves customer trust. Over time, such dialogue often leads buyers to share more projects, because they see the supplier as attentive and technically reliable.

Trustbridge Tip: Want to stand out to strategic buyers? Use the Kraljic Matrix to position yourself as a high-value, low-risk partner. Highlight your innovation, reliability, and ESG strengths to move from overlooked to indispensable. Read the full blog

6. Accelerate Response Time — Because Speed Wins

Procurement research consistently shows that early responders gain a psychological edge. Studies suggest 35–50% of deals go to the supplier who quotes first (Inventive AI) ,not necessarily the cheapest. Buyers interpret speed as capability.

In machining, time is often money. Quoting software, pre-approved pricing matrices, and quick-response teams can cut RFQ turnaround from days to hours. Suppliers who consistently deliver in 24–48 hours rise above slower competitors.

Deep approach:

To manage this speed sustainably, suppliers can build “RFQ response categories”:

- Simple repeat jobs: respond within 12–24 hours.

- Moderate complexity: respond within 48 hours.

- New design or tight tolerances: respond within 3–4 days, with staged estimates.

Using pre-set goals keeps expectations realistic and measurable. Over time, it also provides data for internal improvement allowing suppliers to track their “RFQ velocity” and continuously optimize. Obviously, the timelines above are guidelines, but the ability to move even faster is better.

7. Communicate Value, Not Just Price

In a world full of low-cost vendors, CNC suppliers must compete on value clarity, not price noise. A quote that only lists numbers is easily ignored. But a quote that explains why it’s priced that way with emphasis on quality controls, certifications (ISO, AS9100), precision tolerances, or faster delivery stands out.

Storytelling within the quote works powerfully. For example, a short paragraph explaining how the supplier’s in-house metrology reduces inspection costs for the buyer can tip the scale. Transparency transforms perception from a vendor to a manufacturing partner.

Deeper Insight:

Suppliers should use a dedicated “value statement” section in their RFQ responses. It can cover:

- In-house quality assurance systems

- Advanced machining capabilities (5-axis, live-tooling)

- Previous successful projects

- Sustainability or traceability commitments

When buyers read that a supplier’s price includes reliability and support, not just machining time, they perceive real worth.

Trustbridge Tip: Want to turn data into negotiation power? Use AI-powered LLM pilots to forecast demand accurately and identify hidden negotiation levers. Show buyers you’re proactive, strategic, and ready to adapt—making your business indispensable. Read the full blog

8. Combine Ballpark and Detailed Quotes

Sometimes buyers need a quick figure to plan budgets not a fully costed analysis. In these cases, offering a two-stage response helps suppliers stay visible and responsive. Stage one: provide a ballpark quote within hours, including key assumptions and estimated lead times. Stage two: follow up with a detailed breakdown once design reviews and confirmations are complete.

This hybrid approach ensures that the supplier is in the buyer’s consideration set early while still maintaining accuracy later. It shows flexibility and understanding of real-world procurement pressures.

Deeper Insight:

Suppliers can pre-define which RFQ types qualify for this: prototype parts, unclear volumes, or complex assemblies. The ballpark quote should highlight assumptions for example, “pricing assumes 6061-T6 material, 100-piece volume, and standard finish.” That transparency builds trust. When the final quote arrives, it feels like a natural progression rather than a surprise revision.

9. Leverage Modern Quoting and RFQ Management Tools

Manual spreadsheets can’t keep up with the pace of modern manufacturing. Digital RFQ platforms now integrate CAD analysis, material pricing APIs, and labor estimation algorithms. Suppliers using these tools respond faster, more consistently, and with fewer human errors.

According to aPriori, suppliers that adopt automated cost-estimation systems can reduce quoting cycle time by up to 50%, freeing engineers to focus on complex, high-value projects.

Deeper Insight:

An ideal setup connects quoting software to ERP and CRM systems. As soon as an RFQ enters, the system log's part details, calculates preliminary costs, and assigns it to the right engineer. Built-in dashboards track response time, approval status, and success rates. Even small-scale suppliers can adopt lightweight tools like Paperless Parts or MFG.com to modernize workflows. The payoff? Less manual work, more strategic quoting.

10. Monitor, Learn, and Continuously Improve

Finally, no RFQ process stays perfect forever. Markets evolve, material costs fluctuate, and buyer expectations shift. The most successful suppliers treat RFQ performance like a living system, measured, analyzed, and optimized.

Maintaining a “quote feedback database” helps. Every won or lost RFQ should record reasons for the outcome. If a quote was lost due to higher pricing, analyze whether it was cost, speed, or communication that missed the mark. If it was won, identify what worked that’s your repeatable formula.

Deeper Insight:

Quarterly performance reviews can include metrics like average response time, quote-to-win ratio, and cost accuracy. Continuous feedback loops enable smarter decision-making. Over time, this builds a culture of accountability and precision, the hallmark of modern, customer-centric CNC suppliers.

Final Thought

In 2025, improving RFQ response rate is no longer a task, it’s a strategic advantage. Buyers are looking for suppliers who combine speed, transparency, and reliability. By embracing automation, data, communication, and continuous learning, CNC machining suppliers can transform the RFQ process into a powerful business growth engine.

Are you a talented manufacturer seeking to grow your customer base? Join the Trustbridge Manufacturing Network to be provided direct access to RFP and RFQ opportunities that are aligned with your specific expertise. Explore Trustbridge for Suppliers

FAQs (4 questions)

Q1: Why is a fast RFQ response critical for CNC machining suppliers?

A1: Faster RFQ responses help suppliers win more business, build credibility with buyers, and stay competitive in a market where speed often outweighs price. Delayed responses can result in lost opportunities and a weakened reputation.

Q2: How can CNC suppliers use historical data to improve RFQ accuracy?

A2: By analyzing past quotes and completed jobs, suppliers can benchmark costs, estimate machining times, and identify pricing trends. This reduces under- or over-quoting and ensures more accurate and confident submissions.

Q3: What role do modern RFQ management tools play?

A3: Digital quoting and RFQ platforms streamline workflows, integrate material pricing and CAD analysis, reduce errors, and accelerate response times. These tools enable suppliers to handle higher volumes efficiently while maintaining accuracy.

Q4: How can suppliers maintain continuous improvement in RFQ processes?

A4: Suppliers can track metrics such as average response time, quote-to-win ratio, and cost accuracy. By reviewing won and lost RFQs regularly, they can identify patterns, refine processes, and adopt best practices to improve efficiency and win rates.