OEM Manufacturing: What Buyers Must Know Before Releasing a Part for Production

OEM manufacturing decisions carry long-term consequences for cost, quality, and supply continuity often locking in risk before the first production order is placed. Once a part is released into the OEM manufacturing process, buyers are accountable not only for price and lead time, but also for whether the supplier can produce that part consistently, repeatedly, and at scale. Many production issues blamed on suppliers originate earlier, when parts are approved without full supplier validation, manufacturability review, or production-readiness checks.

In OEM manufacturing, buyers operate at the intersection of engineering intent and factory reality. They must ensure that released designs can be manufactured reliably as machined parts, molded components, or fabricated assemblies. Understanding how suppliers interpret drawings, materials, and production requirements is critical to avoiding rework, PPAP delays, and costly production interruptions.

This guide explains what buyers need to evaluate before releasing a part into OEM manufacturing, with a focus on production readiness, supplier capability, and long-term risk prevention.

Understanding OEM Manufacturing From a Buyer’s Perspective

OEM manufacturing refers to outsourcing part or product production to a supplier that manufactures to your specifications. For OEM sourcing and supplier quality teams, this relationship extends far beyond issuing a purchase order. It requires confirming that the supplier understands requirements, operates controlled processes, and can maintain consistency over time as part of a validated OEM manufacturing process.

A common buyer mistake is assuming prototype success equals production readiness. In practice:

- Prototype builds test feasibility

- Production runs test repeatability and control

- Serial production exposes variation, drift, and capacity limits

Buyers must evaluate whether suppliers can control variation, maintain documentation, and manage process changes without disrupting production.

Successful OEM manufacturing depends on alignment between buyer expectations and supplier execution and that alignment must be validated through supplier validation before production release, not after failures appear.

Machined Parts: What Buyers Must Validate Before Release

Machined parts are widely used in OEM manufacturing across automotive, industrial equipment, aerospace, and capital machinery programs. From a buyer’s standpoint, machining introduces risk related to tolerance control, fixturing stability, tool wear, and long-term process capability. Even when first-article samples pass inspection, buyers must determine whether the supplier can sustain dimensional accuracy across extended production runs.

Buyers should focus on how machining suppliers manage tool-life tracking, fixture repeatability, inspection methods, and revision control. A shop capable of producing accurate low-volume machined parts may struggle when volumes increase if tooling discipline, process documentation, or inspection capacity is insufficient. Scalability is often the hidden risk in machined parts sourcing.

In OEM manufacturing, buyers should treat machining capability as a production system, not a one-time outcome. The ability to repeat results consistently matters more than initial sample approval.

Cast Parts: Buyer Risks in Tooling and Process Control

Cast parts play a critical role in OEM manufacturing when complex geometry, material efficiency, or cost reduction is required. From a buyer’s perspective, casting introduces risks tied to tooling design, process stability, and internal defect control. Issues such as porosity, shrinkage, and dimensional variation often surface only after production volumes increase.

Buyers must confirm that casting suppliers have validated tooling, controlled melting and pouring processes, and reliable inspection methods. Material traceability and consistency are particularly important, as unauthorized changes in alloy composition can impact mechanical performance and downstream machining.

Unlike machined parts, cast components often involve longer tooling lead times and higher switching costs. Buyers should ensure that casting processes are fully validated before production release to avoid expensive retooling or supplier changes later.

Forged Parts: Managing Strength, Consistency, and Supply Risk

Forged parts are commonly used in OEM manufacturing where high strength, fatigue resistance, and structural integrity are required. From a buyer’s viewpoint, forging introduces risks related to process consistency, heat treatment control, and dimensional variation following secondary machining.

Buyers must verify that forging suppliers can control billet quality, forging temperatures, and post-forging treatments to ensure consistent mechanical properties. Variability in forging processes can lead to performance deviations that are difficult to detect through dimensional inspection alone.

Because forged parts often support safety-critical applications, buyers should confirm that suppliers maintain robust documentation, traceability, and change-management processes. Early validation reduces the risk of downstream failures that are costly and difficult to correct once production is underway.

Molded Parts and Low Volume Injection Molding Considerations

Low volume injection molding is frequently used in OEM manufacturing for pilot builds, early production phases, or market validation. Buyers often select this approach to reduce upfront tooling investment and preserve flexibility, but low volume does not equate to low risk.

Buyers must ensure that molded parts produced during low-volume phases reflect future production intent. Material selection, tooling design, and quality controls should align with long-term requirements. Shortcuts taken during early molding stages often result in costly requalification, tooling changes, or supplier transitions when volumes increase.

For OEM manufacturing, buyers should clearly define whether low volume injection molding is a temporary bridge or a long-term production solution. Alignment on tooling strategy and quality expectations is essential to avoiding future disruptions.

The Role of PPAP in OEM Manufacturing Readiness

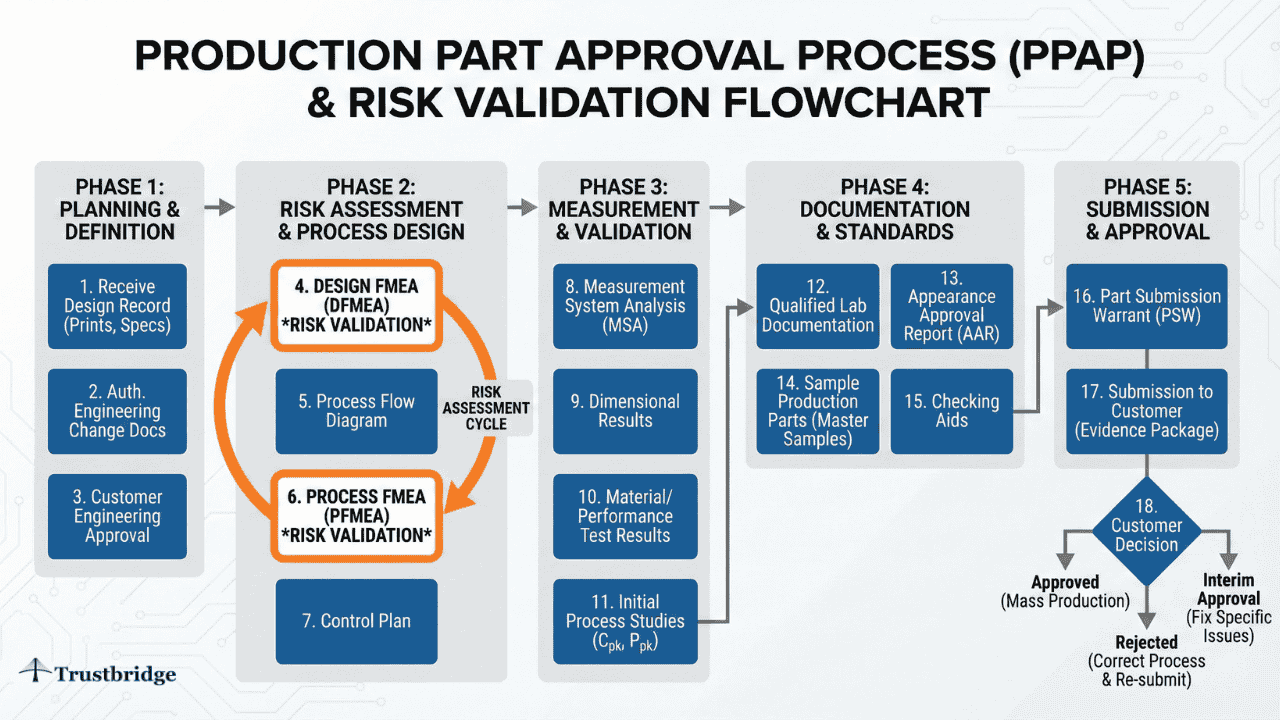

The production part approval process (PPAP) exists to protect buyers from releasing parts that are not production-ready. In OEM manufacturing, PPAP approval confirms that a supplier can produce parts meeting specifications consistently, using a defined and controlled process.

Buyers should treat PPAP as a risk-management gate, not an administrative formality. A disciplined PPAP checklist typically validates:

- Material sourcing and certifications

- Process flow and control plans

- Measurement systems and inspection plans

- Capability studies on critical dimensions

- Change-management and revision control

When PPAP reviews are rushed or incomplete, risk is simply deferred into live production.

[NEW – Simple flow-style summary] PPAP risk validation flow: Design approval → Process definition → Trial production → Capability validation → PPAP sign-off → Production release

Strong PPAP discipline helps buyers surface issues during validation when correction is manageable rather than during active production, when delays, shortages, and customer impact escalate quickly.

Low Volume Injection Molding and Buyer Expectations

Low volume injection molding is frequently used in OEM manufacturing for pilot builds, early production, or market testing. Buyers often select this approach to reduce upfront tooling investment and preserve flexibility.

However, low volume does not equal low risk. Buyers must confirm:

- Tooling reflects future production intent

- Materials match long-term specifications

- Quality controls are scalable

Shortcuts taken during low-volume phases often become costly requalification issues later.

Buyers should clarify whether low volume injection molding is a temporary bridge or a long-term solution. Supplier alignment on tooling strategy, material selection, and quality controls is essential to avoid redesigns, tooling changes, or supplier transitions down the line.

Material Selection Risks Buyers Must Manage

Material selection plays a decisive role in OEM manufacturing success. Buyers must understand how material choices affect sourcing risk, lead times, compliance, and manufacturability.

Common material-related risks include:

- Misunderstanding ferrous vs nonferrous metals

- Regional sourcing constraints

- Certification and compliance gaps

- Unauthorized substitutions

Ferrous materials often provide strength and cost advantages but may introduce corrosion or weight concerns. Nonferrous materials may improve corrosion resistance or weight reduction yet bring higher cost or sourcing constraints.

Buyers should confirm that suppliers can source materials consistently, maintain certifications, and preserve traceability. Unauthorized material substitutions remain one of the most common causes of quality escapes in OEM manufacturing.

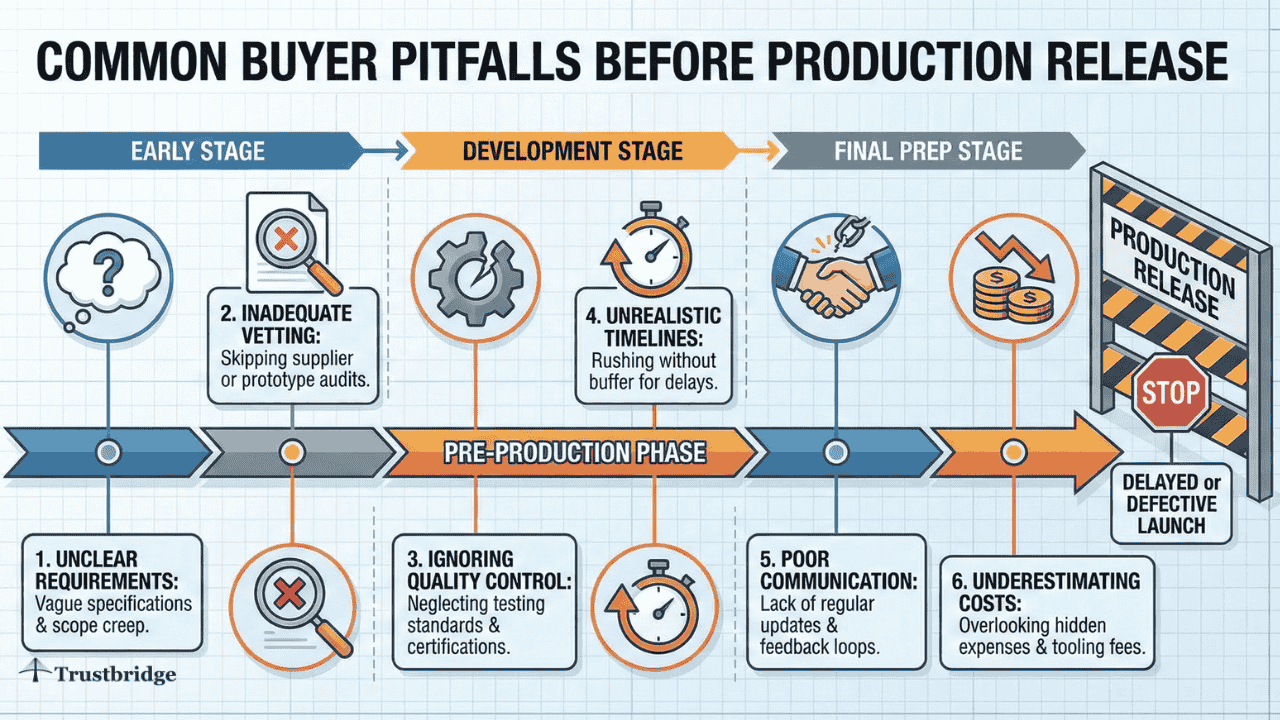

Common Buyer Pitfalls Before Production Release

One of the most frequent buyer errors is releasing parts based solely on sample approval. A part that passes initial inspection may still fail under production conditions due to process drift, operator variation, or insufficient controls.

Another risk is assuming undocumented expectations are understood. Surface finish, packaging standards, inspection frequency, and handling requirements must be explicitly defined. When they are not, suppliers default to internal norms often creating conflict after production begins.

Buyers should also avoid over-reliance on a single supplier without validating contingency options. Capacity constraints, financial instability, or external disruptions can quickly expose single-source vulnerabilities.

How Buyers Can Reduce Risk Before Releasing a Part

Risk reduction begins with structured validation before production release. Buyers should confirm that suppliers have qualified processes, defined inspection plans, and clear change-management procedures.

Early supplier engagement during production planning allows buyers to identify tooling, material, and capacity risks before they become schedule-critical.

Before releasing any part to production, disciplined OEM buyers use a supplier validation checklist:

- Process capability validated

- PPAP completed and reviewed

- Material sourcing and traceability confirmed

- Capacity and scalability verified

This checklist mindset prevents many downstream failures.

Trustbridge Tip: A strong OEM manufacturing process relies not just on technical readiness, but on strategic sourcing decisions that align engineering, quality, and supply continuity. Many production issues stem from missteps in supplier validation, contract scope, or alignment on expectations not machining execution alone. The blog Manufacturing Teams Get Sourcing Wrong highlights common gaps where sourcing teams fail to align supplier capability with long-term production needs.

To strengthen your supplier validation and reduce the risk of production surprises, deepen early engagement with sourcing and quality partners, clarify expectations up front, and leverage documented processes like PPAP checklists and supplier performance metrics.

To explore how sourcing misalignment can undermine production outcomes and what teams can do differently, read our blog: Manufacturing Teams Get Sourcing Wrong and How to Fix It.Aligning OEM Manufacturing With Long-Term Supply Strategy

OEM manufacturing decisions should support long-term supply strategy—not just short-term unit cost targets. Buyers who focus solely on price often underestimate risks tied to quality, scalability, and supplier resilience.

Evaluating suppliers based on process maturity, communication discipline, and historical performance provides a clearer picture of long-term value. Buyers should assess whether suppliers can support future design changes, regulatory requirements, and volume growth.

A well-aligned OEM manufacturing strategy minimizes firefighting and allows buyers to focus on optimization rather than reactive problem-solving.

Conclusion:

By validating machined part processes, applying a disciplined PPAP checklist, aligning low volume injection molding with production intent, and managing material risks proactively, OEM buyers protect continuity and performance.

These insights come from observing repeated OEM production failures where early warning signs were ignored. Disciplined buyers prevent issues others spend months fixing.

Trustbridge supports buyers by providing the tools, insights, and expertise needed to execute strategic quote comparisons at scale. Ready to transform your sourcing decisions? Visit Trustbridge.pro to explore resources, case studies, and solutions designed to help procurement professionals make smarter, more confident buying decisions.

Frequently Asked Questions (FAQs)

1. Why do OEM production issues often appear after parts are released to manufacturing?

Most production issues are locked in before the first order is placed. When OEM buyers release parts without fully validating manufacturability, supplier processes, or material sourcing, problems surface later as quality escapes, delays, or rework—when fixes are far more costly.

2. What should OEM buyers validate before approving a part for production release?

Before production release, buyers should confirm supplier process capability, inspection controls, material traceability, PPAP readiness, and capacity to scale. Sample approval alone does not guarantee consistent, repeatable production.

3. Why is supplier validation critical in the OEM manufacturing process?

Supplier validation ensures a vendor can sustain serial production, not just produce prototypes. It confirms process control, documentation discipline, and the ability to manage variation—reducing supply chain risk during full-scale production.

4. How does PPAP protect OEM buyers during production launch?

PPAP acts as a risk-control gate in the OEM manufacturing process. It verifies that parts can be produced consistently using a defined, controlled process. Treating PPAP seriously helps buyers catch issues during validation instead of during live production.