How to Compare Supplier Quotes: A Buyer's Guide to Making Smart Sourcing Decisions

Buyers face this scenario every day: multiple supplier quotes arrive, each claiming to offer the best value. Three suppliers quote the same item at different prices, one at $45, another at $50, and a third at $42. The instinct? Choose the lowest price. But experienced buyers know this decision can be a trap that costs far more than the initial savings. The real challenge isn't collecting quotes; it's comparing them intelligently. A lower price can hide quality compromises, delivery delays, or hidden fees that emerge only after commitment. Without a structured comparison framework, buying decisions become guesses dressed up as strategy. Budgets suffer, operations stumble, and buyer credibility takes the hit when the "best deal" becomes the worst headache.

The solution lies in a methodical, data-driven quote comparison process. For buyers, this means moving beyond price alone to evaluate total cost, supplier reliability, quality standards, and long-term value. It transforms quote evaluation from a rushed approval exercise into strategic sourcing that protects margins, ensures consistency, and builds dependable supply chains.

What Does It Mean to Compare Supplier Quotes?

Comparing supplier quotes is the process buyers use to evaluate multiple pricing proposals from different suppliers for the same product or service. It goes far beyond spotting the lowest number on a spreadsheet. A thorough quote comparison examines pricing structure, payment terms, delivery schedules, quality specifications, warranty coverage, and supplier track record. Think of it as due diligence for every purchase decision.

Buyers must ask:

Are we comparing apples to apples?

Does this quote include everything we need?

What risks are hidden in the fine print?

Without answering these questions, even the most attractive quote can lead to budget overruns, production delays, or quality failures.

For procurement teams, quote comparison is where strategy meets execution. It's the checkpoint that determines whether a sourcing decision will deliver value or create problems. A structured approach ensures that every purchase is evaluated consistently, objectively, and in alignment with business priorities.

Core Factors to Evaluate When Comparing Supplier Quotes

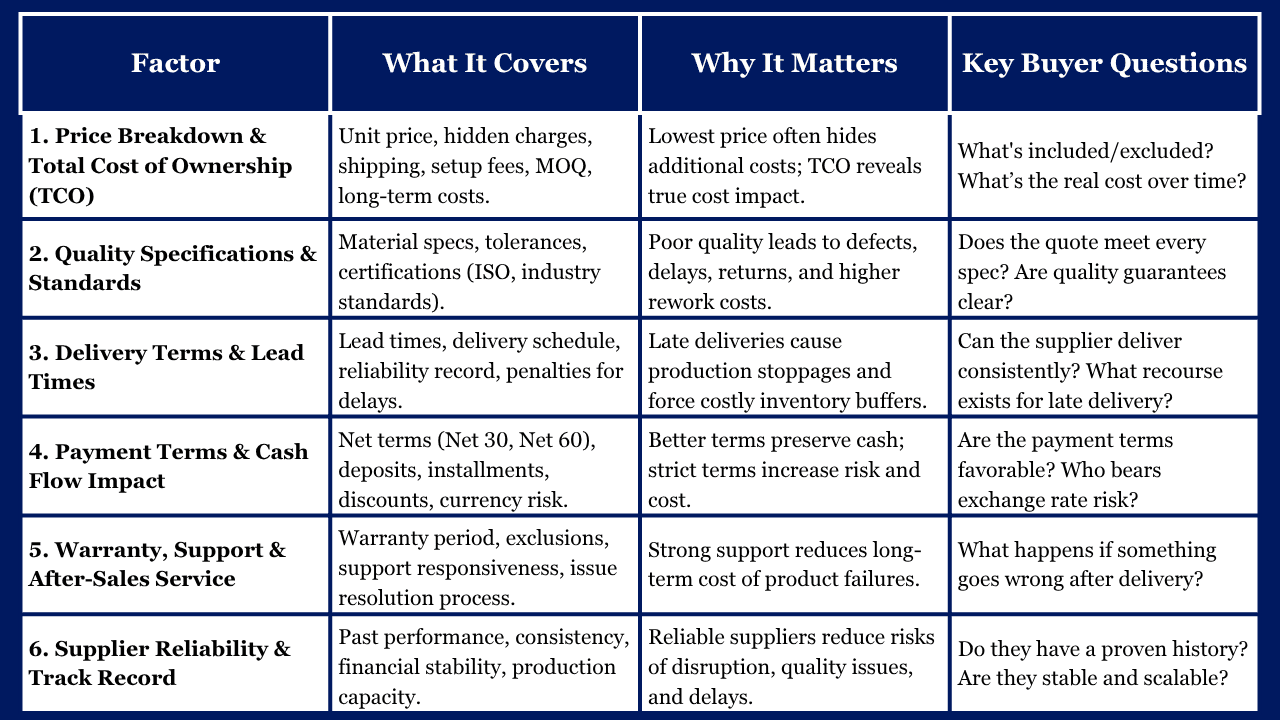

A supplier quote is more than a price tag—it's a package of commitments, risks, and value drivers. For buyers, effective quote comparison means looking beyond the headline number to understand what's actually being offered. Here are the critical factors buyers must evaluate to make informed decisions.

For procurement teams, supplier reliability directly affects risk management. A new supplier quoting aggressively low may lack the experience or resources to deliver consistently. An established supplier with proven performance may quote higher but offers predictability that protects operations. By considering track record alongside price, buyers make sourcing decisions that balance opportunity with prudence.

Designing a Quote Comparison Process That Works

Creating an effective quote comparison process requires more than spreadsheets and good intentions. For buyers, the goal is to build a systematic approach that ensures consistency, reduces bias, and enables confident decision-making. Here's how buyers can design a comparison process that delivers results.

For example, if late deliveries have become a recurring problem, buyers might increase the weight assigned to delivery reliability in future evaluations. If sustainability has become a corporate priority, environmental criteria might be added to the scoring system. This continuous improvement ensures the process remains relevant and aligned with organizational goals.

Using Quote Comparison Insights for Strategic Sourcing

Once buyers have thoroughly compared supplier quotes, the insights gained extend far beyond the immediate purchase decision. These insights can shape long-term sourcing strategies, improve supplier negotiations, and build more resilient supply chains. Here's how buyers can leverage quote comparison data strategically.

1. Identify Cost Benchmarks and Market Trends

By comparing multiple quotes for similar items over time, buyers develop a clear understanding of market pricing and cost trends. This intelligence helps them recognize when a quote is genuinely competitive versus when it's inflated or suspiciously low. Cost benchmarking also strengthens negotiation leverage, as buyers can reference market rates when discussing pricing with suppliers.

For example, if three suppliers consistently quote between $48-52 for a component, a buyer knows that a $65 quote is likely overpriced while a $35 quote deserves scrutiny for hidden compromises. This knowledge protects procurement teams from both overpaying and underbuying in ways that create quality or reliability risks.

2. Segment Suppliers Based on Value Proposition

Quote comparison reveals which suppliers compete on price, which differentiate through quality or service, and which offer balanced value. Buyers can use this segmentation to match suppliers with appropriate sourcing categories and strategies.

For instance, low-cost suppliers might be suitable for non-critical commodities where price is paramount. Quality-focused suppliers are better matched to critical components where performance matters most. Balanced suppliers work well for strategic partnerships where multiple factors contribute to long-term value. This segmentation helps buyers allocate business strategically, maximizing value across their entire supplier portfolio.

3. Strengthen Negotiation and Contract Discussions

Armed with detailed quote comparison data, buyers enter negotiations from a position of strength. They can point to specific differences between suppliers to justify requests for better pricing, improved terms, or enhanced service commitments. Concrete data makes negotiations fact-based rather than adversarial.

For example, a buyer might say: "Supplier A offered Net 60 terms while you quoted Net 30. Can you match that?" or "Your quality specifications were less detailed than competitors—can you clarify your compliance processes?" This approach keeps discussions constructive while pressing for better outcomes.

4. Build Supplier Relationships Through Transparency

When buyers share evaluation criteria openly and explain how quotes were compared, suppliers understand what matters to the organization. This transparency builds trust and encourages suppliers to submit more competitive, complete quotes in future opportunities. Suppliers who know they'll be evaluated on total value—not just price—are more likely to invest in quality, service, and innovation.

Trustbridge Tip: Rushing quote comparisons or focusing only on price often leads to poor supplier choices that create long-term costs and operational headaches. To understand how low-price decisions can undermine profitability, read our detailed insight: Your Lowest Bidder May Be a Hidden Cost Disaster. Are You Considering the Full Potential Cost? | Trustbridge

Common Pitfalls Buyers Should Avoid When Comparing Quotes

Even with a solid framework, quote comparison can go wrong if buyers fall into common traps. Being aware of these pitfalls helps procurement teams make better decisions and avoid costly mistakes. Let's explore the most frequent errors and how to avoid them.

1. Focusing Only on Price

The most pervasive mistake is treating price as the only decision factor. When buyers automatically choose the lowest quote without evaluating quality, delivery, or supplier reliability, they often create problems that cost far more than the initial savings. Hidden costs—defects, delays, poor service—quickly erode any price advantage.

Instead, buyers should evaluate total value, considering all factors that affect cost, risk, and performance. The lowest price is worth pursuing only when quality, delivery, and reliability are equal across suppliers, which is rarely the case.

2. Comparing Incomplete or Inconsistent Quotes

Quotes that don't address all requirements can't be compared accurately. When suppliers provide different levels of detail, omit key specifications, or make varying assumptions, comparison becomes guesswork. Buyers must ensure all quotes cover the same scope, or request clarifications to fill gaps.

The solution is a standardized RFQ that clearly defines what must be included in every quote. If quotes arrive incomplete, buyers should send follow-up requests rather than making assumptions that may prove incorrect after award.

3. Ignoring Supplier Capability and Track Record

A supplier can quote anything, but delivering on that promise requires capability and reliability. Buyers who ignore supplier track records risk choosing partners who can't fulfill commitments, leading to quality failures, delivery delays, or business disruptions.

Before selecting a supplier based on their quote, buyers should verify: Do they have experience with similar products or services? What's their delivery and quality history? Are they financially stable? A supplier with a strong track record may be worth a price premium over an unknown or unreliable alternative.

4. Failing to Document the Comparison Process

When buyers don't document how they compared quotes or why they made their selection, they create problems for future accountability and improvement. Undocumented decisions are hard to defend when questioned by stakeholders or auditors, and they provide no learning for future sourcing cycles.

Buyers should maintain clear records of evaluation criteria, scoring, assumptions, and rationale for the final decision. This documentation protects against challenges and helps refine the process over time.

5. Making Decisions in Isolation

Quote comparison shouldn't happen in a vacuum. Buyers who make decisions without input from quality, engineering, operations, or finance teams risk overlooking critical requirements or constraints. Collaborative evaluation ensures that all perspectives inform the decision, reducing the likelihood of costly oversights.

Involving stakeholders early, ideally during RFQ development, ensures everyone agrees on evaluation criteria before quotes arrive. This alignment speeds decision-making and builds support for the final selection.

Conclusion: Turning Quote Comparison into Strategic Advantage

For buyers, comparing supplier quotes isn't just a procurement task, it's a strategic capability that drives cost efficiency, quality assurance, and supply chain resilience. When done systematically, quote comparison transforms supplier selection from guesswork into evidence-based decision-making that protects margins and supports operational success.

By evaluating total value rather than just price, documenting decisions transparently, and learning from each sourcing cycle, buyers build institutional knowledge that strengthens their organization's competitive position. Over time, this discipline creates a supplier network that delivers consistent value, reliable performance, and collaborative partnerships.

In the long run, mastering quote comparison elevates procurement from a cost center into a strategic function; one that contributes measurably to profitability, innovation, and business growth. For buyers, that's not just better sourcing; it's competitive advantage.

Trustbridge supports buyers by providing the tools, insights, and expertise needed to execute strategic quote comparisons at scale. Ready to transform your sourcing decisions? Visit Trustbridge.pro to explore resources, case studies, and solutions designed to help procurement professionals make smarter, more confident buying decisions.

Frequently Asked Questions

1. What's the best way to compare supplier quotes?

The best approach is to use a structured framework that evaluates multiple factors—price, quality, delivery, payment terms, and supplier reliability—using weighted scoring to align with business priorities.

2. Should I always choose the lowest-priced quote?

No. The lowest price often hides quality compromises, delivery delays, or hidden costs. Buyers should evaluate total cost of ownership and value, not just the quoted price.

3. How do I ensure I'm comparing apples to apples?

Start with a standardized RFQ that clearly specifies requirements, quantities, quality standards, and delivery expectations. Ensure all suppliers respond to the same scope before comparing quotes.

4. What factors matter most when comparing quotes?

It depends on business priorities, but typically: total cost of ownership, quality specifications, delivery reliability, payment terms, and supplier track record are the most critical factors.

5. How can I justify choosing a higher-priced supplier?

Use a documented comparison process with weighted scoring that shows how the supplier's advantages in quality, delivery, service, or reliability offset the higher price, resulting in better total value.