6 Critical Considerations for Successful OEM Manufacturing

OEM manufacturing is not simply about executing drawings or meeting volume targets. For suppliers, it represents ownership of production outcomes—quality, delivery, and repeatability—instead of task execution. It is a discipline that blends production readiness, process control, quality validation, and scalability. When preparation falls short, the impact is tangible: increased scrap costs, delayed start of production (SOP), expedited recovery efforts, and potential OEM penalties. In many cases, the difference between a smooth production launch and a costly disruption comes down to how thoroughly a supplier prepares before the first part ever ships.

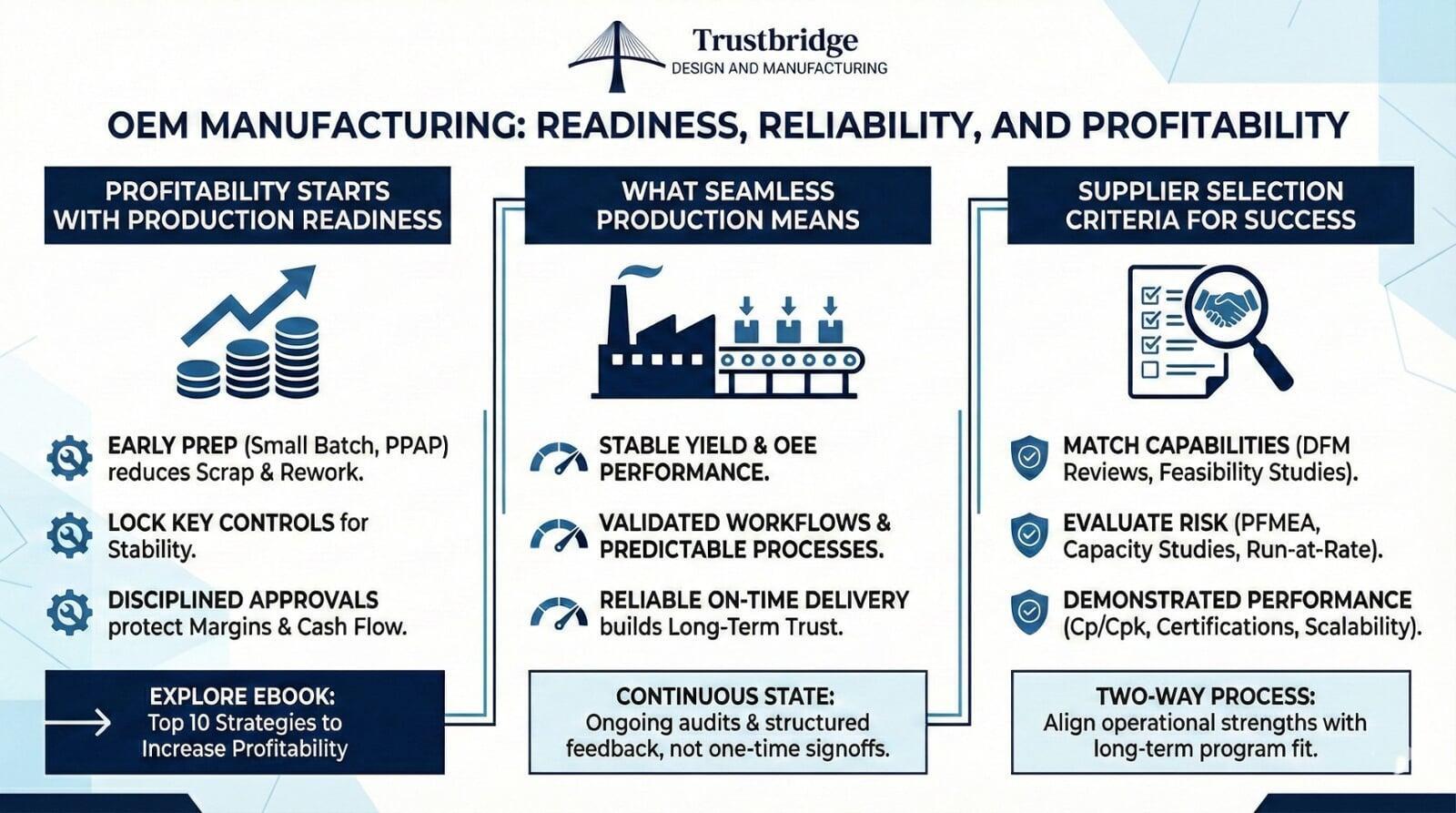

In modern OEM manufacturing environments, suppliers face mounting pressure from shorter lead times, higher mix–lower volume production, tighter tolerances, and growing regulatory and compliance requirements. Seamless production is not accidental—it is built through structured preparation supported by formal systems such as APQP planning, disciplined PPAP execution, robust control plans, and cross-functional alignment across operations, engineering, and quality teams.

This blog explains how suppliers prepare for seamless OEM manufacturing and what separates production-ready suppliers from those that struggle during scale-up.

What Seamless Production Means in OEM Manufacturing

Seamless production in OEM manufacturing refers to a supplier’s ability to transition from initial production runs to sustained output without quality hiccups, delivery disruptions, or excessive rework. In practical terms, this is reflected through stable first-pass yield, consistent product performance, and reliable on-time delivery. For suppliers, seamless production depends on predictable processes, validated workflows, and capacity that supports long-term demand.

From an OEM perspective, predictability at the supplier level directly affects downstream assembly lines, system integration, and customer delivery commitments. Variability at any upstream operation can cascade into line stoppages, inventory imbalances, and increased cost across the value chain.

Production readiness is not a single milestone or approval event. It is a continuous state that suppliers must maintain across tooling, labor, inspection, documentation, and change management. This requires ongoing audits, structured feedback loops, and performance reviews—not one-time signoffs. OEM customers ultimately reward suppliers who deliver consistency with trust, repeat business, and long-term contracts.

Supplier Selection Criteria That Enable OEM Manufacturing Success

Strong OEM manufacturing outcomes begin with disciplined supplier selection criteria, and this evaluation is a two-way process. While OEMs assess suppliers, suppliers must also evaluate whether a program aligns with their operational strengths, capacity roadmap, and commercial structure.

Beyond technical capability, suppliers must consider margin sustainability, contract terms, volume commitments, and long-term program fit alongside operational readiness.

Supplier selection criteria typically focus on demonstrated performance indicators such as:

Demonstrated process capability through measurable Cp/Cpk targets

Proven quality systems maturity supported by ISO, AS, or IATF certifications

Proven scalability reflected in historical on-time delivery and capacity utilization

These criteria help suppliers avoid overcommitting to programs that introduce unnecessary technical, operational, or commercial risk.

Matching Capabilities to OEM Requirements

Suppliers that succeed in OEM manufacturing clearly understand what they can and cannot support. Capability gaps are identified through structured DFM reviews, manufacturing feasibility studies, and early production simulations. These evaluations assess tolerances, materials, part complexity, and volume expectations.

Effective capability assessment is cross-functional by design, involving engineering, quality, and operations to ensure alignment before production commitments are made.

Risk Evaluation Before Production Commitment

Before committing to production, suppliers conduct formal risk assessments to identify potential challenges across technical, operational, and human factors. Common tools include PFMEA, capacity studies, and run-at-rate evaluations. These assessments uncover risks related to tooling robustness, inspection throughput, operator training, and labor availability.

Addressing these risks early supports smoother production launches and reduces the likelihood of OEM escalation during ramp-up.

The Role of Supplier Certifications in OEM Manufacturing

Supplier certifications play a critical role in OEM manufacturing readiness. Certifications such as ISO 9001, AS9100, IATF 16949, and ISO 13485 demonstrate that suppliers operate within structured quality frameworks and maintain disciplined process controls. These certifications validate system rigor—not just documentation.

OEM customers rely on certifications to reduce risk and ensure compliance, particularly in regulated or high-precision industries where process discipline is non-negotiable.

Why Certifications Support Production Stability

Certifications standardize how suppliers manage documentation, training, corrective actions, and audits. They establish a baseline level of operational control and reduce operator-to-operator variability through defined procedures and work instructions. While certifications are not a differentiator on their own, they are a foundational requirement for seamless OEM manufacturing.

Maintaining Certification Compliance at Scale

As production volumes grow, maintaining certification compliance becomes more complex. Suppliers must rely on proactive internal audits, management reviews, and performance monitoring rather than reactive corrective actions. This ensures that procedures, inspections, and training scale alongside output without introducing variability.

Using Small Batch Manufacturing to Prepare for Scale

Small batch manufacturing is a critical preparation step in OEM manufacturing and differs fundamentally from prototyping. These runs use production tooling, real operators, and standard inspection processes to replicate full-scale conditions. Small batch manufacturing allows suppliers to validate processes under realistic constraints before committing to volume production.

Validation activities during this phase include monitoring first-pass yield, cycle time stability, and inspection throughput.

These runs provide real-world insight into cycle times, scrap rates, and inspection requirements, often producing measurable outputs such as baseline yield percentages and takt time benchmarks.

Process Validation Through Early Runs

During small batch manufacturing, suppliers analyze production data to confirm process stability. Key indicators include Cp/Cpk performance, first-pass yield consistency, unplanned downtime, and variation trends. Adjustments made at this stage significantly reduce disruptions later in production.

Reducing Ramp-Up Risk

Resolving issues during small batch manufacturing helps suppliers avoid specific ramp-up risks such as tooling rework, inspection bottlenecks, and unbalanced work cells. By stabilizing processes early, suppliers reduce the need for OEM intervention during launch and improve confidence heading into volume production.

Custom Manufacturing and Supplier Flexibility

OEM manufacturing often requires custom manufacturing approaches that go beyond standard process variation. Custom requirements may include specialized materials, unique finishes, or tighter-than-normal tolerances. Suppliers must adapt tooling, workflows, and inspection plans while maintaining control and repeatability.

Custom manufacturing does not mean improvisation—it requires disciplined planning through DFM reviews, PFMEA development, and detailed process mapping.

Translating Requirements Into Stable Processes

Suppliers translate custom requirements into stable processes by addressing manufacturability across three dimensions: design feasibility, tooling robustness, and inspection strategy. Early collaboration with OEM engineering teams ensures that requirements are achievable within production constraints.

Scaling Custom Processes Without Losing Control

As volumes increase, suppliers lock key process parameters, inspection frequencies, tooling settings, and setup conditions. Standard work instructions and visual controls ensure that custom manufacturing remains stable and repeatable at scale.

The PPAP Process and OEM Manufacturing Validation

The PPAP process is a cornerstone of OEM manufacturing readiness, supporting validation from pre-SOP through full production. PPAP confirms that a supplier’s production process—not just sample parts—can consistently produce conforming output.

PPAP validates both product and process, ensuring alignment across materials, tooling, inspection, and control plans.

What the PPAP Process Confirms

The PPAP process confirms material compliance, dimensional accuracy, and process capability. It ensures that results achieved during trials translate into sustained production performance.

Using PPAP to Enable Seamless Launches

Suppliers that treat PPAP as a collaborative validation process rather than a documentation exercise experience smoother launches and fewer late-stage changes. Effective PPAP execution strengthens OEM relationships and reduces launch volatility.

Sustaining Long-Term Stability in OEM Manufacturing

Seamless OEM manufacturing does not stop at launch. Suppliers must continuously monitor performance, maintain equipment, and refine processes to sustain production stability. Data tracking, preventive maintenance, and structured feedback loops allow suppliers to identify trends early and prevent disruptions before they escalate.

Why Supplier Preparation Defines OEM Manufacturing Outcomes

OEM manufacturing success is defined by preparation, not reaction. Suppliers that apply disciplined selection criteria, maintain certifications, validate processes through small batch manufacturing, and execute structured PPAP processes are far better positioned for seamless production.

When these elements work together, suppliers move beyond execution and become trusted OEM manufacturing partners.

Conclusion

Seamless OEM manufacturing does not begin on the shop floor—it begins with supplier preparation. From evaluating opportunities using clear supplier selection criteria to maintaining certifications, validating processes through small batch manufacturing, and executing disciplined PPAP processes, every step contributes to production stability.

Suppliers that succeed in OEM manufacturing take a proactive approach. They invest time upfront to align capabilities with requirements, design custom manufacturing processes that scale, and implement controls that support consistency throughout the life of a program. This preparation reduces risk, minimizes disruptions, and builds long-term trust with OEM partners.

In an environment where delays and quality issues can ripple across entire supply chains, suppliers that prioritize readiness are best positioned to deliver reliable outcomes. OEM manufacturing rewards those who prepare early, execute consistently, and treat production readiness as an ongoing responsibility—not a one-time event.

Trustbridge Tip: Many OEM programs struggle not because of design intent, but because production readiness was not established early enough. Suppliers that evaluate requirements upfront, align capabilities, and validate processes before scale are better positioned to support first-product launches and long-term programs. If you’re focused on improving outcomes during early production phases, our ebook Top 10 Things to Do When Improving on Your First Product outlines practical steps suppliers can apply to reduce risk and build OEM confidence.

Seamless OEM manufacturing starts with supplier readiness. Evaluating production capabilities, validating processes early, and aligning quality systems with OEM expectations significantly reduces risk and improves long-term performance.

If you want to strengthen your OEM manufacturing readiness, now is the time to build the systems, discipline, and accountability that support seamless production—before the next program launches.

Frequently Asked Questions (FAQs)

1. Why is supplier preparation critical in OEM manufacturing?

Supplier preparation determines whether production launches smoothly or breaks down under pressure. In OEM manufacturing, poor preparation can lead to scrap, delayed start of production, missed delivery commitments, and OEM penalties. Suppliers that validate processes, capacity, and quality systems early reduce risk and protect long-term program performance.

2. What supplier certifications matter most in OEM manufacturing?

Certifications such as ISO 9001, AS9100, IATF 16949, and ISO 13485 are critical in OEM manufacturing. They demonstrate that suppliers operate within disciplined quality systems, maintain process control, and are audit-ready. For OEMs, these certifications reduce compliance risk and increase confidence in supplier reliability.

3. How does small batch manufacturing help suppliers prepare for full-scale production?

Small batch manufacturing allows suppliers to run real production tooling with actual operators and inspection plans. These early runs validate cycle times, first-pass yield, and process capability, helping suppliers identify issues before scaling. This step significantly reduces launch disruptions and OEM intervention.

4. What role does the PPAP process play in seamless OEM manufacturing?

The PPAP process confirms that a supplier’s production process—not just sample parts—can consistently meet OEM requirements. It validates materials, dimensions, and process capability before approval for volume production, enabling smoother launches and stronger supplier–OEM alignment.