The Designer’s Imperative for Manufacturability

As a product designer, you probably spend most of your time inside CAD systems, sketching parts, refining geometry, and perfecting assemblies. But here’s the catch: designing a part in CAD is only half the story. The other half is whether that part can actually be manufactured efficiently, reliably, and cost-effectively. That’s where design for manufacturability (DFM) comes in.

When you embrace DFM, you shift your mindset. Instead of just asking “How will this look or work?” you start asking “How will this be made?” and “How can I make it easier and smarter to manufacture?” Think of it this way: CAD gives you the map, but DFM is the navigation system that helps you reach production without detours like unexpected costs, delays, or scrap. Without that navigation, you might design something that looks great on screen, but manufacturing struggles, costs spike, and deadlines slip.

In this blog, I’ll walk you through why CAD alone isn’t enough, how to apply DFM thinking in a practical way, the latest tools and trends shaping the field, and what to watch for as the industry evolves.

What Is Design for Manufacturability (DFM)?

Design for Manufacturability (DFM) means designing a product in a way that makes it easy, cost-effective, and efficient to manufacture without compromising its quality or function. In simple words, it’s about thinking ahead, making sure that what you create on a computer (in CAD) can be made smoothly in the real world using available tools, materials, and production methods.

The goal of DFM is to reduce mistakes, lower production costs, save time, and avoid redesigning later in the process. It helps designers and engineers work together from the very start so that a product not only looks great but is also practical to produce. Essentially, DFM bridges the gap between design and manufacturing, turning creative ideas into products that are both beautiful and buildable.

The Designer’s Dilemma: Bridging the Digital-to-Physical Gap

Every designer faces a moment when a perfect CAD model doesn’t translate into a perfect product. Maybe a curve is too tight for a machine to cut, or a part can’t be molded without complex tooling. These moments remind you that design isn’t just an artistic exercise; it’s a balance between creativity and capability. Design for manufacturability is what turns a digital idea into a physical reality. When you design without considering how something will be made, you risk creating parts that are expensive, fragile, or even impossible to produce. This leads to revisions, wasted time, and higher costs. The more changes you make later, the more expensive and frustrating the process becomes. It’s like designing a car without thinking about the road it will drive on. It might look great, but it won’t perform. The goal isn’t to design less, but to design smarter, with manufacturability as your compass.

Why CAD Alone Falls Short

1. CAD Only Captures Geometry, Not Constraints

When you’re designing CAD, your focus is often on shape, function, fit and appearance. You’re thinking: “Will it assemble? Will it look good? Does it meet the spec?” But manufacturing cares about different realities: tooling, machines, set-up time, batch size, repeatability. CAD alone doesn’t automatically reflect whether a part is easy to manufacture. For example, you might model a complex undercut or a wall that’s very thin, but a mold maker or machine shop may say “This is going to cost extra or may not work without special tooling.” When you design for manufacturability, you ask: “Does what I’ve drawn make sense for how it will be made?” If you don’t ask that, you risk late design changes, cost overruns, or manufacturing delays.

2. Hand-off Friction Between Design and Manufacturing

Another issue is communication. You hand over a CAD model, maybe some drawings, and the manufacturing picks it up—then they ask a dozen questions, or worse, they struggle silently, and the product launch slips. That hand-off friction happens because CAD often describes what the part is, but manufacturing needs to know how and with what it will be made. If you design with manufacturability in mind, you embed manufacturing intent early: you choose processes, you define tolerances that make sense, you think about tooling and supplier capability. That means fewer surprises after design freeze, fewer “we’ll fix it in manufacturing” moments. It often means faster time-to-market and lower cost of quality.

3. Modern Manufacturing Complexity

Manufacturing today is more complex than ever—global supply chains, mix of technologies (injection moulding, sheet-metal, machining, composites, additive), sustainability pressures, shorter product lifecycles. Designing in CAD without thinking about manufacturability means ignoring those realities. If you design for manufacturability, you think about supplier capabilities, tooling lead times, material availability, how many vendors can do the job in a cost-effective way. You’re thinking not just “Can this part fit” but “Can it be made tomorrow, in volume, and without nightmare cost or scrap.” When you neglect manufacturability, you risk designing something that looks great on the screen but becomes a manufacturing headache.

So, how can you start applying these ideas in your daily design work? Let’s break it down into a practical checklist

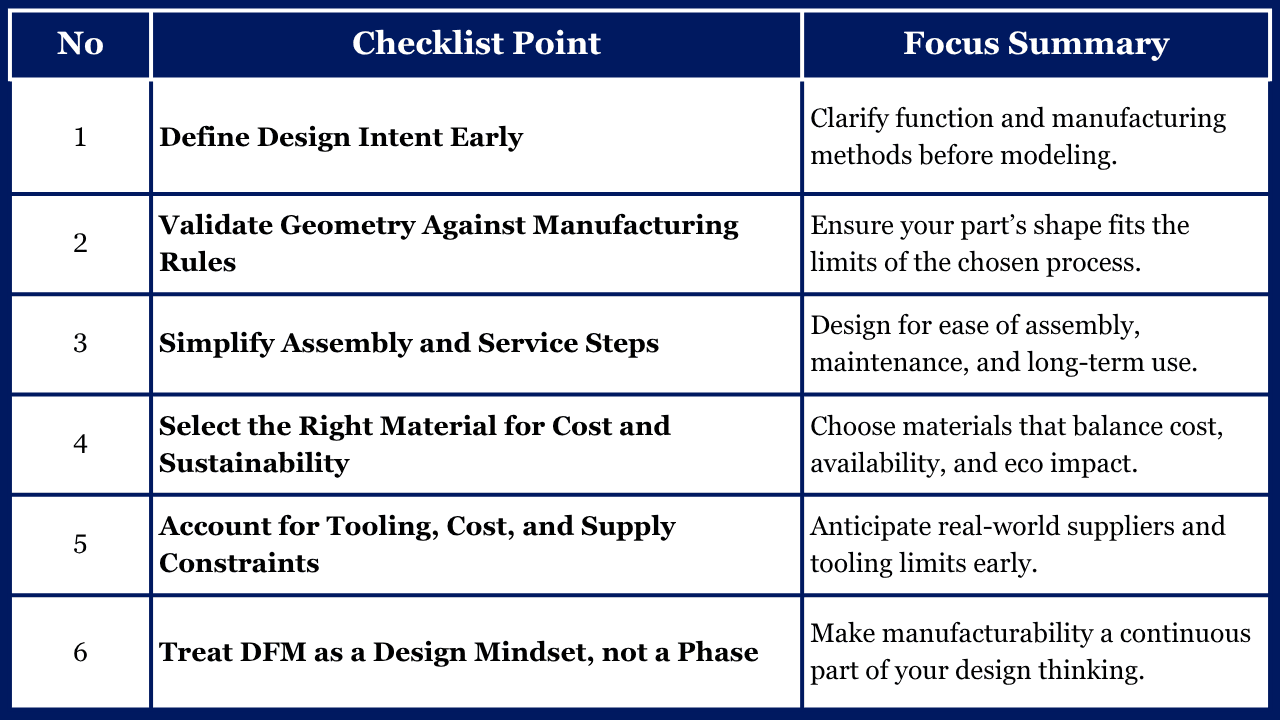

Designer’s Point of View: Practical Design for Manufacturability Checklist

As a designer, treat design for manufacturability as a checklist you run while modeling, not after. Every decision you make in CAD affects cost, quality, and production speed. Here’s how to think like a manufacturer right from your design desk.

Do you want to put these checklist points into practice? Swipe down to see how each step translates from design intent to real-world manufacturability.

1. Define Design Intent Early

At the start of your design process, pause and clarify the purpose of the part.

Ask: What is this part supposed to do, and how will it be made?

Selecting the right manufacturing method upfront (like injection molding, sheet metal, or CNC machining) helps you avoid late-stage redesigns caused by incompatible geometry.

How to implement:

- Write down the part’s key functions and performance requirements before opening CAD.

- Identify the likely manufacturing method and confirm feasibility with your engineering or supplier team.

- Establish key tolerances (fit, motion, clearance) early — this sets the standard for manufacturability later.

- Use design intent-driven constraints in CAD (parametric features) so adjustments remain aligned with manufacturing limits.

2. Validate Geometry Against Manufacturing Rules

Once you know the process, ensure your part geometry fits its rules.

Thin walls, deep pockets, sharp corners, or undercuts often drive up costs or create production headaches. Designing for manufacturability means shaping geometry to match how machines and tools actually work.

How to implement:

- For Injection Molding: Ensure wall thickness consistency (avoid sudden transitions), add draft angles (1–3° minimum), and minimize unnecessary ribs or bosses.

- For Machining: Avoid deep cavities or features that require special tooling. Reduce the number of setups by aligning faces and features logically.

- Use simulation tools or DFM plugins in CAD to flag risky geometry automatically.

- Collaborate with manufacturing engineers early — they can spot design flaws long before production.

3. Simplify Assembly and Service Steps

Manufacturing doesn’t end when a single part is made, it continues when those parts come together. A well-designed assembly saves time, reduces errors, and improves serviceability throughout the product’s life.

How to implement:

- Reduce the number of components — fewer parts mean fewer points of failure.

- Replace fasteners where possible with snap-fits, tabs, or integrated locking features.

- Align screw directions for easy tool access during assembly.

- Plan for serviceability: design housing or panels that can be easily open for maintenance.

- Create exploded-view CAD models to visualize and test assembly sequences before finalizing design.

4. Select the Right Material for Cost and Sustainability

Material selection impacts not only the look and strength of a product but also how easily it can be manufactured and at what cost. Manufacturability-minded designers consider availability, machinability, recyclability, and environmental impact, not just performance specs.

How to implement:

- Research material machinability or molding behavior early in the design phase.

- Choose locally available materials to reduce supply chain risks and cost.

- Consider replacing exotic alloys or resins with common alternatives that offer similar properties.

- Use design guides from material suppliers to understand limitations like minimum radius, shrink rate, and heat resistance.

- Evaluate lifecycle impact: can this material be recycled or reused? Sustainability increasingly influences manufacturing decisions.

5. Account for Tooling, Cost, and Supply Constraints

Tooling and supplier realities can make or break a production plan. Even a perfect CAD design can stall if tooling is too expensive, or there’s only one supplier who can produce it.

How to implement:

- Discuss tooling options with suppliers early — ask about cost, lead time, and standard tool availability.

- If you expect low-volume production, consider methods like additive manufacturing or soft tooling to save costs.

- Design parts that can use standard components (threads, inserts, holes) instead of custom features.

- Plan for scalability — if production grows, your design should scale without needing complete redesigns.

- Document supplier feedback and integrate it into your design revisions — this closes the DFM loop.

6. Treat DFM as a Design Mindset, Not a Phase

Design for manufacturability isn’t a step you check off at the end,it’s a lens you look through at every stage of design. By embedding manufacturability thinking from concept to CAD to production, you not only save cost and time but also build products that perform better, last longer, and make life easier for everyone downstream from machinists to customers.

Trustbridge Tip: Want your CAD designs to move smoothly from concept to production? The key lies in smart, manufacturable design decisions. Learn how applying Design for Manufacturability (DFM) principles helps you minimize costly rework, reduce machining time, and ensure every part is production-ready. Dive into the full breakdown in this blog: From CAD to CNC: Design Decisions That Make-or-Break Manufacturability.

How Modern Tools Help and Where They Still Need You

Generative Design and Topology Optimization

In recent years, many CAD systems offer “generative design” or “topology optimization” features. These let you feed in goals (like minimize weight, maintain strength) and the software proposes shapes, often organic or unusual forms. From a design for manufacturability viewpoint, this is both exciting and cautionary. It’s exciting because you may find designs you wouldn’t have thought of and that meet function very well. But it’s cautionary because many of those shapes may be hard to manufacture. They may require special tooling, complex machines, or add cost. So as a designer, you still need to apply manufacturability checks: “Is this shape realistic for our manufacturing process? Will it cost too much to tool or assemble?” The generative design gives you possibilities, but you must apply design for manufacturability filters to pick the ones that are practical.

Simulation, DFM Software, and Digital Thread

Modern design workflows increasingly integrate simulation tools (stress analysis, deformation, thermal behaviour) and design for manufacturability (DFM) checks inside CAD. They also integrate the “digital thread”—meaning you carry forward manufacturing data, material data, supplier data, process capability all along with the CAD model. For you as a designer this means you have more power: you can check manufacturability earlier, you can adjust geometry for production constraints before tooling starts. But you also need to drive this: you must ask yourself what the manufacturing realities are, ensure your model has the right annotations, communicate with manufacturing teams, and make sure the data flows forward. Simply using CAD doesn’t guarantee manufacturability; you must leverage these tools with manufacturability in mind.

Additive Manufacturing and DfAM (Design for Additive Manufacturing)

Additive manufacturing (3D-printing technologies) opens exciting geometry freedom. But even here, design for manufacturability matters: you may print something, but if it takes many hours, needs support structures, needs costly post-processing, or uses exotic powder, the cost per piece may go up; the supply chain may get complex. From a designer’s point of view, you ask: “Is additive the best method for this part at the expected volume? Will it be cost-effective? Will the finish or features meet quality?” If you apply design for manufacturability for additive methods (sometimes called Design for Additive Manufacturing, or DfM), you’ll pick geometries and features that take advantage of additive strengths and align with real-world cost and quality constraints.

Industry Trends Designers Should Watch

Even if you’re not a manufacturing engineer, as a designer you should keep an eye on these broader trends because they will impact how you apply design for manufacturability.

1. Digital Thread and Model-Based Definition (MBD):

More companies are embedding manufacturing intent, tolerances, process data directly into CAD models so the design and manufacturing teams share the same data. This enables fewer hand-off delays and fewer misinterpretations—so design for manufacturability becomes simpler when the data flows.

2. DFM automation and rules-based checks in CAD:

Tools now include automatic checks of manufacturability constraints (walls too thin, undercuts, draft missing). As a designer, you’ll increasingly work in environments where design for manufacturability rules are partly automated meaning you need to learn and apply these rules early.

3. Generative design adoption tied to manufacturability workflows:

As mentioned above, companies are combining generative design with manufacturability constraints—so designers can get innovative shapes and shapes that are manufacturable.

4. Supply-chain resilience and regionalization:

Especially post-global disruption, designers must keep supply-chain realities in mind: local supplier capability, material scarcity, lead-time variability. When you design with manufacturability, you factor in supplier geography, alternate vendors, material availability.

5. Sustainability as a manufacturability metric:

It’s increasingly not just cost or speed, but also environmental footprint—waste, scrap, recyclability, energy usage. From a design for manufacturability view, you aim to minimize waste, reuse materials, and simplify processes—so manufacturing can not only be cost-effective but also sustainable.

Conclusion:

If you enjoy working in CAD, that’s your creative space and that’s where great ideas begin. But designing parts that can be made is just as critical as designing parts that look good on screen. The real test of design isn’t just visual perfection; it’s how smoothly that design moves from concept to production. When you start thinking about manufacturability early, you’re not limiting creativity; you’re making it real, practical, and valuable. Every time you pause to ask, “Can this be made efficiently?” You’re building confidence in both your design and its execution. Design for manufacturability isn’t a separate task; it’s a mindset that turns you from a CAD operator into a complete product designer. By considering manufacturing constraints as you design, collaborating with engineers and suppliers, and choosing smarter materials and processes, you save time, cut cost, and build trust across teams. Ultimately, your best designs aren’t just the ones that look impressive, they’re the ones that get made, perform well, and stand the test of time.

Ready to move your procurement from spreadsheets to strategy? AI is no longer optional — it’s the backbone of modern buying. Empower your procurement team with intelligent sourcing, real-time spend visibility, and smarter decision-making. Visit Trustbridge.pro to explore buyer resources, case studies, and solutions designed to help procurement professionals lead with confidence.

Frequently Asked Questions

1. What is Design for Manufacturability and why is it important?

Design for Manufacturability (DFM) is the practice of designing products so they can be produced efficiently, cost-effectively, and with high quality. It helps you identify potential manufacturing challenges early in the design stage, reducing rework, delays, and unexpected costs. In short, DFM ensures that your design isn’t just functional—it’s buildable.

2. How is DFM different from regular CAD design?

CAD design focuses on geometry, fit, and aesthetics—how a part looks and functions in theory. DFM goes a step further by considering how that part will actually be made. It looks at factors like tooling, material choice, tolerances, and process constraints to make sure your design is practical and manufacturable.

3. When should a designer start thinking about manufacturability?

The best time to start applying DFM principles is right from the beginning of the design process. Making manufacturability decisions early—such as choosing the right materials, tolerances, and processes—prevents costly design changes later. Early DFM thinking leads to faster product development and fewer production headaches.

4. Can modern CAD tools automatically ensure manufacturability?

While many CAD tools now include manufacturability checks and simulation features, they can’t replace designer judgment. Tools can flag thin walls or missing drafts, but they don’t fully understand supplier capabilities, tooling costs, or real-world assembly challenges. Designers still need to apply DFM principles to interpret results and make smart design choices.