The Designer's Guide to Augmented Reality (AR) and Virtual Reality (VR): Immersive Technologies That Actually Work in Manufacturing

Design teams in manufacturing face a frustrating paradox: tools get smarter, but communication gaps keep growing. You've refined a product design down to the last millimeter, but operators on the shop floor misinterpret assembly instructions. Prototypes look perfect in CAD yet reveal costly flaws only after tooling begins. Training new team members takes weeks, and even then, spatial understanding of complex assemblies remains hit-or-miss.

The real pain lies in the disconnect between digital intent and physical reality. Traditional 2D drawings, static 3D models, and classroom training can't bridge the gap between what designers envision and what manufacturers execute. Every miscommunication cost time, materials, and credibility. Production delays stack up, design iterations multiply, and quality issues emerge downstream when it's most expensive to fix them.

The solution? Immersive technologies, specifically Augmented Reality (AR) and Virtual Reality (VR), are emerging to close this gap in ways that flat screens never could. These tools bring designs to life in three-dimensional space, transform training from passive observation to active participation, and give designers the power to validate, iterate, and communicate with unprecedented clarity.

What Are AR and VR in the Manufacturing Context?

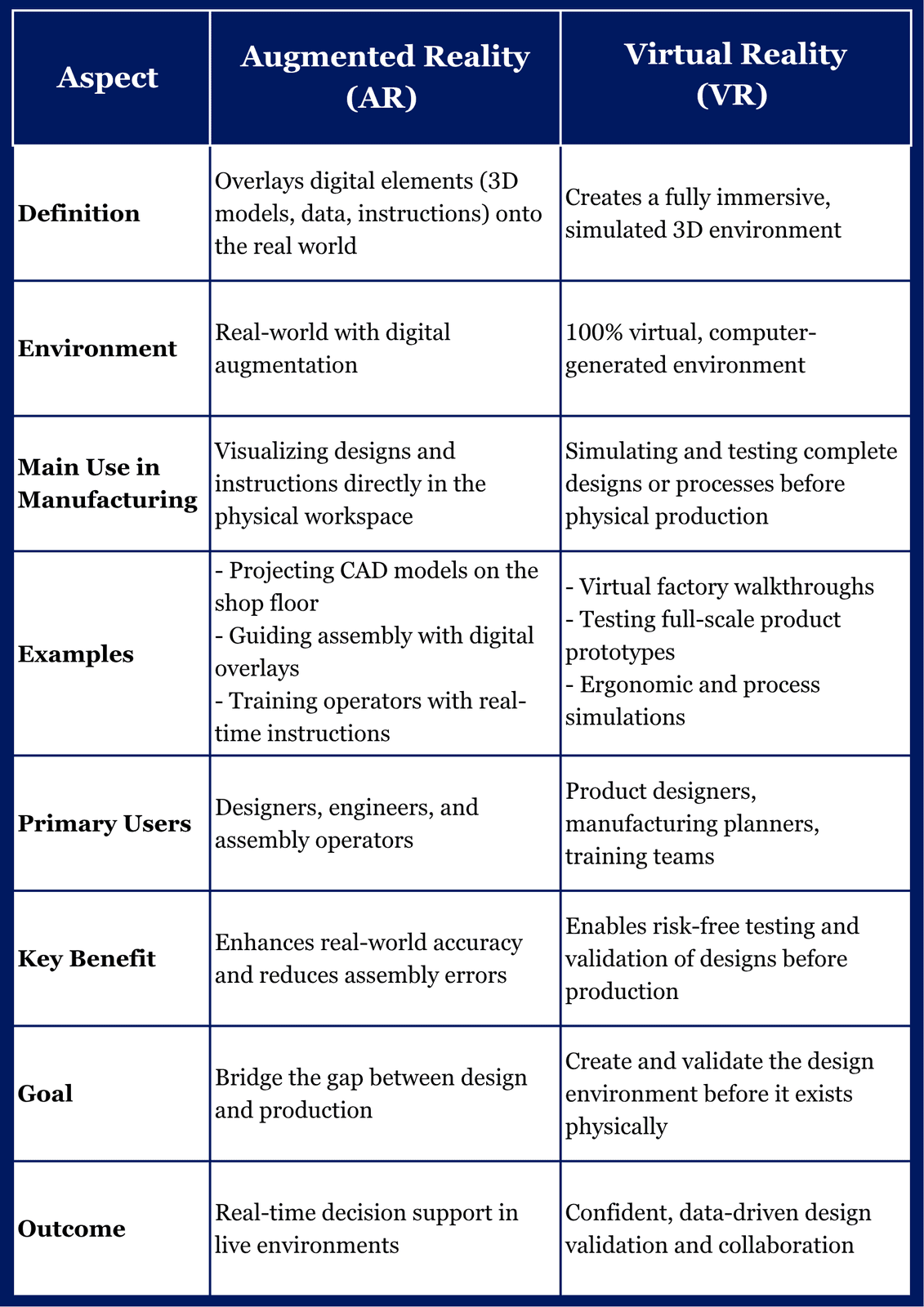

Augmented Reality (AR) and Virtual Reality (VR) aren't just consumer entertainment technologies anymore; they are increasingly being adopted by industrial designers working in manufacturing environments. While AR and VR are often mentioned together, they serve distinct but complementary purposes.

For designers, these technologies answer critical questions: Does this design actually work in the real environment? Can operators assemble it correctly? Will it fit? These aren't theoretical concerns, they directly affect manufacturability, cost, and quality. AR and VR move design validation from guesswork to high confidence, transforming how designers collaborate with engineers, operators, and stakeholders across the manufacturing ecosystem.

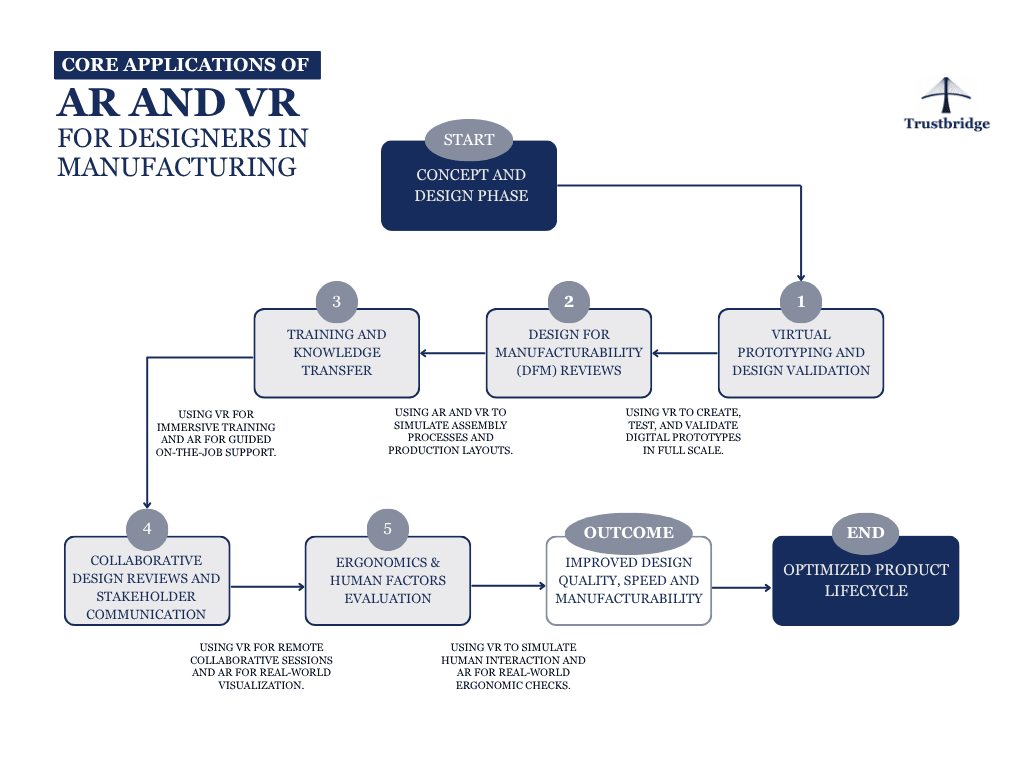

Core Applications of AR and VR for Designers in Manufacturing

Immersive technologies offer designers a powerful toolkit that spans the entire product lifecycle, from initial concept to full-scale production. Understanding where and how AR and VR deliver the most value helps designers integrate these tools strategically into their workflows. Let's explore the key applications that directly impact design quality, speed, and manufacturability.

In VR, designers can simulate real-world operator interactions with their products. They can test reach distances, evaluate sightlines, assess force requirements, and identify awkward postures that could lead to strain or injury. Motion capture technology can be integrated into VR environments to track how users move and interact, providing quantitative data that designers can use to optimize their designs.

AR complements this by enabling real-world ergonomic evaluations. Designers can project digital models onto physical workspaces and ask operators to simulate interactions. This hybrid approach combines the flexibility of digital design with the authenticity of real-world environments, ensuring that ergonomic considerations are validated in context.

By integrating ergonomic evaluation into the design process through AR and VR, designers create products that are not only manufacturable but also comfortable and safe to use. This proactive approach reduces the need for costly redesigns after production begins and demonstrates a commitment to worker well-being, a priority that resonates across manufacturing organizations.

Trustbridge Tip: Ignoring mould-friendly geometry and draft angles may save you a few bucks today, but will cost you in rejects, delays and hidden tooling expense tomorrow. Read this Trustbridge blog to learn more: Which Rules Should Be Kept In Mind When Designing for Injection Molding? | Trustbridge

Designing with AR and VR: Best Practices for Manufacturers

Adopting AR and VR isn't just about acquiring new tools; it's about integrating them thoughtfully into existing design workflows. For designers in manufacturing, success depends on how these technologies complement traditional methods and enhance collaboration across teams. Let's explore practical strategies to maximize the value of immersive technologies without disrupting proven processes.

1. Start with High-Impact Use Cases

Not every design task benefits equally from AR or VR. Designers should prioritize applications where immersive technologies deliver the most value. Focus on complex assemblies, products with tight spatial constraints, or designs where operator interaction is critical. For example, if you're designing a piece of industrial equipment with multiple subassemblies and intricate serviceability requirements, VR can catch issues that would be invisible in CAD.

Starting with high-impact use cases builds internal momentum and demonstrates ROI quickly. Once stakeholders see tangible benefits, such as reduced prototyping costs or faster design approvals, it becomes easier to expand AR and VR adoption across broader design activities. This focused approach also allows designers to learn the tools deeply in contexts where they matter most, rather than spreading efforts too thin.

2. Integrate AR and VR into Existing CAD Workflows

AR and VR should enhance, not replace, established design processes. The most successful implementations integrate seamlessly with existing CAD systems, allowing designers to move fluidly between traditional modeling and immersive validation. Many modern CAD platforms offer plugins or native support for exporting models directly into VR environments or AR viewers.

For designers, this integration means you can continue working in familiar tools while leveraging immersive technologies for specific validation and review tasks. For instance, you might model a product in SolidWorks, export it to a VR platform for an assembly simulation, identify a design issue, and then return to SolidWorks to make adjustments. This iterative loop keeps designers productive without forcing them to abandon the tools they know.

3. Involve Cross-Functional Teams Early

Immersive technologies are most effective when used collaboratively. Designers should involve production engineers, quality teams, operators, and supply chain managers early in the design process. Virtual design reviews in VR or on-site AR evaluations create opportunities for these stakeholders to provide input when changes are still easy and inexpensive to implement.

Cross-functional involvement also builds trust. When stakeholders see that designers are proactively seeking their input and using advanced tools to validate designs, it strengthens relationships and positions design as a strategic partner rather than an isolated function.

4. Set Clear Goals and Measure Outcomes

Like any technology investment, AR and VR should deliver measurable value. Designers and their organizations should establish clear goals for immersive technology adoption, whether it's reducing prototyping costs, shortening design cycles, improving first-time-right rates, or enhancing training effectiveness. Tracking these metrics helps demonstrate ROI and identify areas for improvement.

Setting clear goals also focuses efforts. Instead of using immersive technologies broadly but superficially, designers can concentrate on applications where the benefits are most significant and measurable.

5. Invest in Training and Change Management

Even the most powerful tools are ineffective if users don't know how to leverage them. Designers and their teams need proper training to use AR and VR effectively. This includes technical skills, such as navigating VR environments or setting up AR overlays, as well as strategic skills, like knowing when to use immersive technologies versus traditional methods.

Organizations should also address change management. Some designers may be hesitant to adopt new tools, especially if they're comfortable with existing workflows. Leadership should communicate the strategic value of AR and VR, provide hands-on training, and create a culture that encourages experimentation and learning.

Peer learning can be particularly effective. Designate early adopters as champions who can share best practices, troubleshoot challenges, and demonstrate successful use cases to colleagues. This grassroots approach often drives adoption more effectively than top-down mandates.

6. Prioritize User Experience and Accessibility

AR and VR tools should be intuitive and accessible to all relevant users, from designers to operators. Overly complex interfaces or systems that require extensive technical expertise can limit adoption and reduce effectiveness. When evaluating AR/VR platforms, prioritize those with user-friendly interfaces, strong support resources, and compatibility with existing hardware and software ecosystems.

For designers, this means choosing tools that fit naturally into daily workflows without steep learning curves. For training applications, it means ensuring that AR interfaces are simple enough for operators with varying levels of technical proficiency to use confidently.

Accessibility also extends to hardware. VR headsets should be comfortable for extended use, and AR devices should be lightweight and non-intrusive. Organizations should consider ergonomics and usability when selecting equipment to ensure high adoption rates and sustained use.

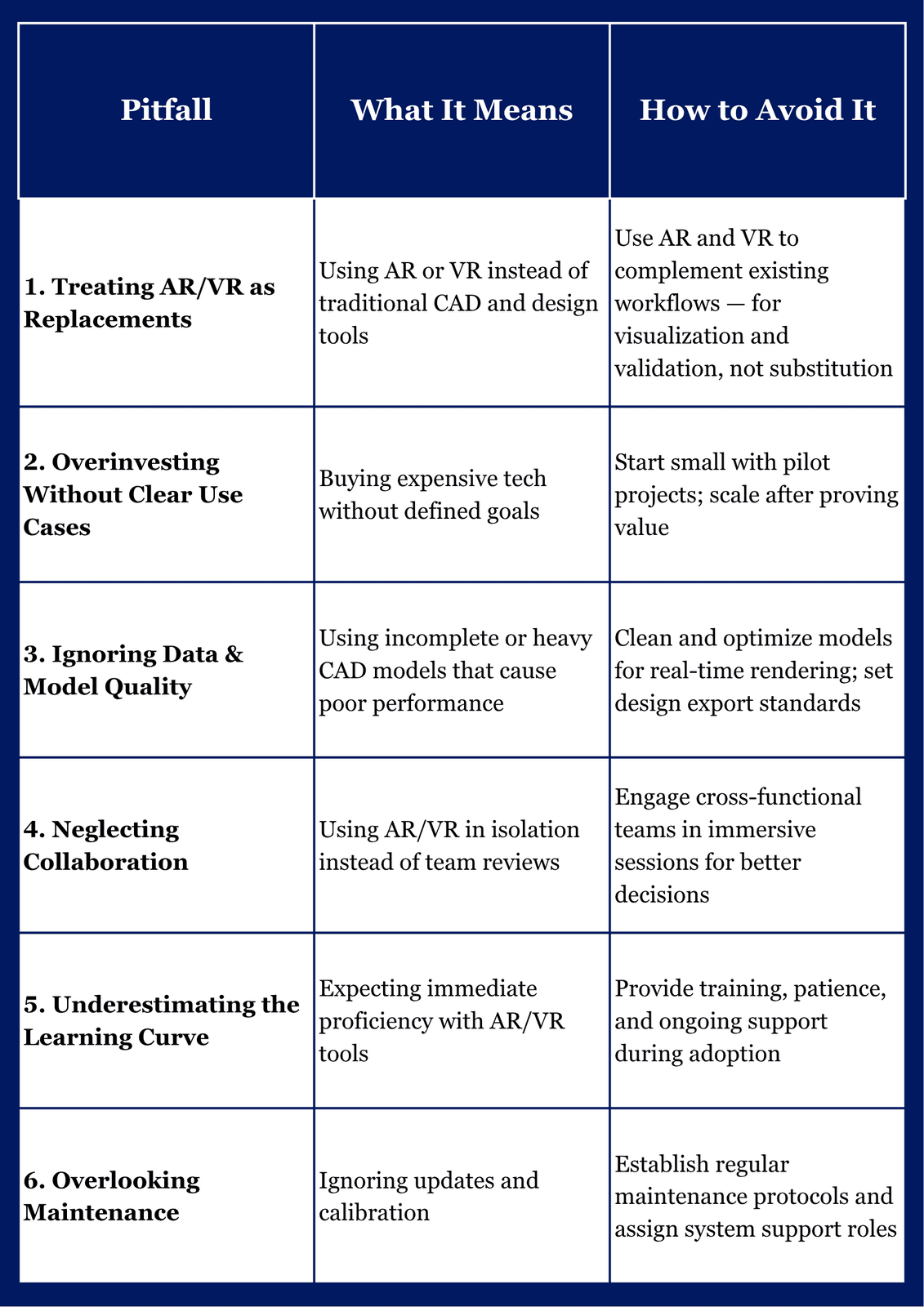

Common Pitfalls Designers Should Avoid with AR and VR

While AR and VR offer tremendous potential, they also come with challenges. Designers who approach these technologies thoughtfully can avoid common mistakes that limit effectiveness or lead to frustration. Let's explore the pitfalls to watch for and how to navigate them successfully.

You can edit text on your website by double clicking on a text box on your website. Alternatively, when you select a text box a settings menu will appear. your website by double clicking on a text box on your website. Alternatively, when you select a text box

Conclusion: Turning Immersive Technologies into a Design Advantage

For designers in manufacturing, AR and VR represent more than just technological upgrades, they're strategic tools that transform how designs are created, validated, and communicated. By enabling spatial validation, collaborative reviews, and proactive manufacturability assessments, immersive technologies compress design cycles, reduce errors, and improve alignment between design intent and production reality.

The most successful designers will be those who integrate AR and VR thoughtfully into their workflows, leveraging these tools where they deliver the most value while maintaining the strengths of traditional design methods. This balanced approach ensures that immersive technologies enhance rather than disrupt proven processes.

Ultimately, AR and VR empower designers to bridge the gap between imagination and execution. They provide clarity where ambiguity once existed, foster collaboration where silos once prevailed, and deliver confidence where uncertainty once slowed progress. For designers ready to embrace these tools, the opportunity is clear: lead the transformation of manufacturing design by making the invisible visible and the impossible achievable.

Trustbridge supports manufacturers by helping them implement advanced technologies and optimize design-to-manufacturing workflows. Ready to bring your designs to life with immersive technologies? Discover how Trustbridge can support your journey. Visit Trustbridge.pro to explore resources, case studies, and solutions designed for forward-thinking designers and manufacturers.

Frequently Asked Questions

1. What is the difference between AR and VR in manufacturing design?

AR (Augmented Reality) overlays digital information onto the physical world, allowing designers to visualize how products fit into real environments. VR (Virtual Reality) creates fully immersive digital environments where designers can interact with and validate products before they're physically built.

2. How do AR and VR reduce prototyping costs?

By enabling designers to create and validate digital prototypes in immersive environments, AR and VR reduce the need for multiple physical prototypes. Issues can be identified and corrected virtually before expensive tooling or manufacturing begins, significantly lowering prototyping costs.

3. Can AR and VR integrate with existing CAD software?

Yes, most modern CAD platforms offer plugins or native support for exporting models to AR and VR environments. This integration allows designers to move seamlessly between traditional modeling and immersive validation without disrupting established workflows.

4. What are the best use cases for designers to start with AR and VR?

Designers should start with complex assemblies, products with tight spatial constraints, ergonomic evaluations, and design-for-manufacturability reviews. These high-impact use cases demonstrate clear value and build organizational confidence in immersive technologies.

5. How do AR and VR improve collaboration in manufacturing design?

Immersive technologies enable shared experiences where designers, engineers, operators, and stakeholders can interact with designs together in real-time. This spatial, interactive collaboration improves communication, accelerates decision-making, and ensures that designs are validated from multiple perspectives before production begins.