How Suppliers Can Leverage Large Language Models to Improve Demand Forecasting and Negotiation

The supply chain environment is more unpredictable than ever. Suppliers face constant pressure to forecast demand accurately, adjust to rapid market changes, and negotiate effectively with buyers. Traditional methods spreadsheets, manual analysis, and historical data are no longer enough to keep up with the pace and complexity of modern supply chains. Mistakes in forecasting or misreading buyer signals can lead to costly stockouts, excess inventory, or missed opportunities.

These challenges can feel overwhelming, especially as the volume of data continues to grow. Purchase orders, emails, market reports, and customer communications create a flood of information that is difficult to analyze manually. Critical patterns often go unnoticed, and suppliers may struggle to react quickly to sudden shifts in demand. This inefficiency not only impacts profitability but also weakens relationships with buyers who expect timely and accurate responses.

This is where Large Language Models (LLMs) come in. These advanced AI systems can process vast amounts of unstructured data, detect hidden trends, and provide actionable insights. By analyzing historical orders, buyer communications, and market signals, LLMs help suppliers make smarter forecasting decisions, optimize negotiations, and respond to market fluctuations with confidence. With small pilot implementations, suppliers can start leveraging AI to streamline operations, reduce errors, and gain a competitive edge in today’s dynamic marketplace.

Why LLMs Matter for Suppliers: Gaining Insights from Human-Centric Information.

Traditional demand forecasting relies on structured data in spreadsheets and databases. While these tools are essential for analysis, much valuable context exists in human-centric information such as contract drafts, emails, and RFPs. LLMs can help suppliers make sense of this information by providing summaries, clarifying details, and highlighting key points that might otherwise be overlooked.

Suppliers can leverage LLMs to:

Summarize long buyer communications or complex documents for easier review.

Clarify and organize information from contracts, RFPs, or emails.

Highlight recurring themes or patterns in communications to support better decision-making.

Pilot Use-Cases Suppliers Can Start With

1. Chat Assistant to Parse Purchase Orders (POs)

One of the biggest sinks of time is handling non-standard or emailed orders. A PO might arrive as an email with attached PDFs, a scanned document, or a combination of text and tables. This unstructured data requires manual review and data entry, leading to delays and errors.

The Pilot: PO-to-Data Automator

LLMs can act as intelligent assistants to read, interpret, and summarize incoming purchase orders. For example, they can flag missing information, unusual quantities, or discrepancies compared to historical orders. This reduces manual review time and minimizes errors that can impact fulfillment.

Feature | How the LLM Helps | Supplier Benefit |

Data Extraction | The LLM is trained to read an unstructured document (email, PDF, image) and extract key fields like Item SKU, Quantity, Requested Delivery Date, PO Number, and Unit Price. | Faster Order-to-Cash Cycle: Orders are processed minutes faster, leading to earlier fulfillment and invoicing. |

Cross-Validation | It cross-references the extracted details against your master product catalog and current pricing rules, flagging any inconsistencies for a human to review. | Reduced Errors: Minimizes costly mistakes like shipping the wrong product or applying the incorrect price. |

Summary & Alert | It generates a concise, structured file ready for direct upload into your ERP system and sends an automated alert if a key field is missing. | Efficiency & Compliance: Frees up customer service or sales support staff from tedious data entry. |

2. Anomaly Detection in Demand Forecasts

Analyzing historical orders can reveal unexpected spikes, drops, or irregular patterns. Your forecast can be easily skewed by a one-time promotional order or a data entry error. LLMs excel in spotting these anomalies early, allowing suppliers to adjust inventory, production schedules, or procurement strategies proactively.

The Pilot: Contextual Data Cleaner

LLMs augment your existing forecasting models by solving the "garbage-in, garbage-out" problem. They don't just flag an anomaly; they attempt to explain it by connecting the numerical data to human-readable context.

Feature | How the LLM Helps | Supplier Benefit |

Pattern Recognition | The LLM analyzes time-series data, identifying sales spikes or drops that deviate statistically from surrounding patterns. | Improved Forecast Accuracy: Traditional models will use a 'cleaner' baseline, leading to fewer stockouts or instances of overstocking. |

Contextual Flagging | It links the numerical anomaly to unstructured text data—like internal promotion memos, customer service logs, or news reports—to provide a root-cause explanation. | Actionable Insights: Provides why the number is an outlier, helping forecasters decide whether to remove the data point or keep it. |

Data Imputation Suggestion | For clear anomalies, the LLM suggests a replacement value based on surrounding weeks' data, providing statistical reasoning. | Faster Data Prep: Cuts down the manual labor of cleaning data for the monthly or quarterly Sales and Operations Planning (S&OP) process. |

3. “What-If” Support for Scenario Planning

Suppliers often need to test multiple scenarios quickly to plan effectively. Manually modeling the impact of a potential change across your entire supply chain is a massive undertaking.

The Pilot: Supply Chain Impact Simulator

LLMs can simulate “what-if” situations—for instance, projecting demand if a major buyer increases their order by 20% or if lead times extend due to supply disruptions. These models help suppliers make more informed decisions and prepare contingency plans, ultimately improving responsiveness and customer satisfaction.

The LLM can read a high-level scenario (e.g., "If our raw material lead time goes from 4 weeks to 8 weeks, what is the impact on on-time delivery for our top 5 customers?") and synthesize data from your inventory, production schedules, and outstanding POs to generate a high-level risk assessment and suggested mitigation steps.

4. Negotiation Intelligence

Effective negotiation is key to profit margin. LLMs can analyze historical contracts, emails, and buyer interactions to suggest optimized pricing strategies, highlight negotiation levers, and even draft persuasive proposals. This can save time, increase win rates, and strengthen relationships with buyers.

The Pilot: Contract and Deal Precedent Analyst

LLMs become your negotiation co-pilot, turning historical data into a strategic advantage.

Feature | How the LLM Helps | Supplier Benefit |

Clause Impact Modeling | You ask a natural language question: "What is the net profit impact if we accept a 60-day payment term instead of 30 days for Customer X?" | Superior Negotiation Position: Instantly quantify the financial risk/reward of concession, allowing your team to negotiate with confidence. |

Best Alternative Suggestion | It analyzes your database of previous negotiations and suggests a precedent or alternative that achieved a better outcome in similar circumstances. | Strategic Agility: Moves the discussion beyond price to optimize total contract value. |

Risk Flagging | It quickly scans a proposed contract term against a library of company-approved language, flagging high-risk or non-standard legal clauses. | Reduced Legal Friction: Speeds up the legal review process and minimizes exposure to unanticipated risk. |

Transform your entire supply chain with intelligent solutions.Visit Trustbridge Pro today to explore how our specialized consulting and LLM integration services can build a resilient, future-proof operation.

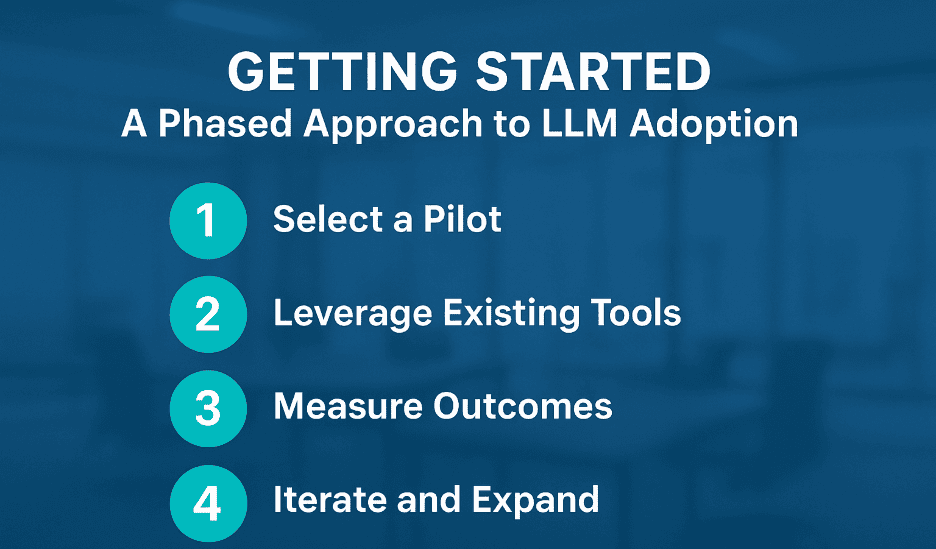

Getting Started: A Phased Approach to LLM Adoption

1. Select a Pilot

Focus on a high-impact, low-risk area like purchase order parsing or anomaly detection where the data is readily available and the task is highly repetitive. A successful pilot should address a clear, frustrating bottleneck—like the manual data entry of unstructured customer documents—to quickly secure internal buy-in. Limiting the scope to a single product line or a specific customer segment makes the project manageable and its results easier to isolate and analyze. This initial win provides the foundational proof of concept needed to justify further investment.

2. Leverage Existing Tools

Many cloud platforms and specialized supply chain tools now offer LLM integration as out-of-the-box features or low-code solutions. Look for solutions that provide an easy-to-use interface (often called a 'copilot' or 'assistant') without requiring deep coding knowledge or hiring expensive data scientists. This approach allows your existing business analysts and operations staff to quickly become power users, ensuring that the technology is adopted smoothly and integrated into daily workflows without major operational disruption. The goal is to plug in LLM intelligence, not rebuild your entire tech stack.

3. Measure Outcomes

Clearly define and track key metrics (Key Performance Indicators or KPIs) from the start. For a data parsing pilot, track the time saved per processed document and the accuracy improvements in data entry, translating this into reduced labor costs and fewer fulfillment errors. For forecasting, measure the reduction in Mean Absolute Percentage Error (MAPE) for the pilot product line. These measurable outcomes are essential for calculating a clear Return on Investment (ROI), which will be critical when seeking budget approval to scale the project.

4. Iterate and Expand

Once initial success is achieved, use the established framework to scale to more complex processes like scenario planning and negotiation support. The lessons learned in the initial pilot—particularly around data quality and user adoption—will be invaluable as you move to higher-stakes applications. This iterative approach allows your organization to gradually build a culture of AI-powered decision-making, transforming LLMs from a simple automation tool into a true strategic asset across your commercial and operational teams.

The Bottom Line

Frequently Asked Questions (FAQs)

1. Do we need to hire a full AI team to start an LLM pilot?

No, you absolutely do not. The starting point for most successful supplier LLM pilots is leveraging existing low-code or specialized LLM solutions integrated into popular supply chain or cloud platforms. These tools are designed for business users to configure and manage. While you may need a single technical expert for initial setup and data connection, the focus is on enabling your existing operational and commercial teams, not building a large research division.

2. How do LLMs handle our sensitive or proprietary supplier data?

Data privacy and security are paramount. It is crucial to use enterprise-grade LLM solutions (often proprietary models run within a secure cloud environment) that guarantee your data is not used to train the public model. For highly sensitive data, consider on-premise or Private LLMs (often smaller, fine-tuned models) that run entirely within your company's firewall. The principle of Retrieval-Augmented Generation (RAG) is also key, as it keeps your proprietary documents separate while allowing the LLM to access them for context.

3. Can an LLM replace our existing statistical forecasting model (e.g., ARIMA or Exponential Smoothing)?

LLMs are best used as complements, not replacements, for traditional statistical models. Your existing models are strong at handling structured time-series data. LLMs excel at processing the unstructured context (emails, news, contracts) that explains why the numbers might change. The most effective approach is a hybrid model: use the LLM to clean historical data (anomaly detection) and incorporate qualitative context, then feed that improved, context-rich data into your proven statistical model for the final forecast.

4. What is the fastest way to get a measurable ROI from an LLM pilot?

The fastest ROI usually comes from automating a high-volume, highly repetitive task that is prone to human error. Purchase Order (PO) parsing is a perfect example. Every minute saved in manually reviewing and entering data from a PO, and every error avoided, translates directly into reduced labor cost and faster order fulfillment. This pilot is simple to set up, requires minimal data, and provides clear time-savings metrics within the first month.