5 Ways CNC Router Programming Influences Precision, Delivery Speed, and Total Cost

Introduction

A single unstable CNC router program can quietly erode margins, delay launches, and trigger quality escalations long before procurement sees a red flag. Yet when buyers evaluate CNC routing suppliers, attention typically centers on machine size, material capability, or quoted price. What often goes unexamined is the strength of the CNC router programs that control motion logic, tool engagement, repeatability, and change management.

For buyers accountable for cost, delivery, and compliance, programming discipline is not a technical detail. It is a direct determinant of scrap exposure, schedule reliability, audit readiness, and long-term supplier performance. Weak programming practices surface later as dimensional drift, missed shipments, corrective action cycles, or failed approvals. Strong programming prevents those issues before they begin.

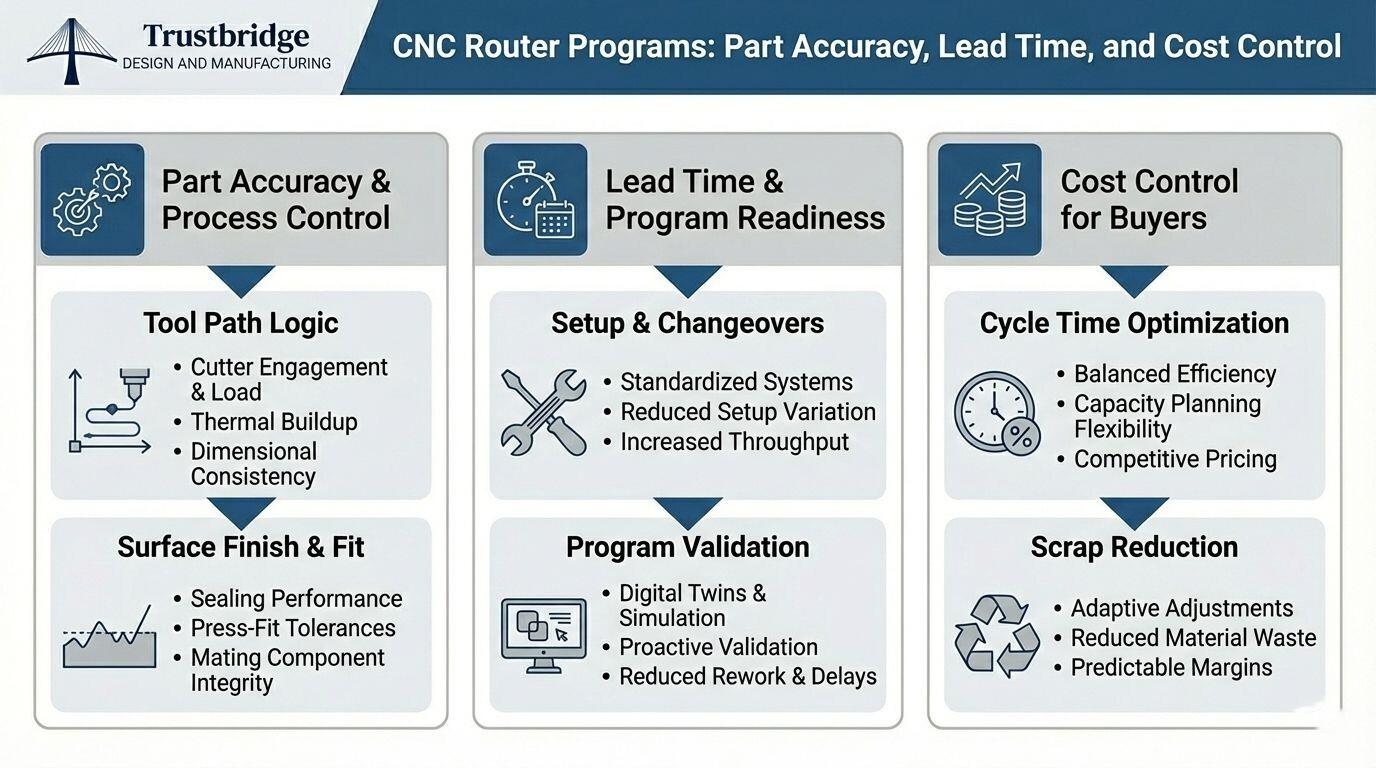

CNC Router Programs and Part Accuracy in Real Production

In prototype builds, a part may pass inspection once and appear acceptable. In production, however, capability must hold across thousands of cycles. CNC router programs determine whether dimensional tolerances remain stable at volume or degrade under real operating conditions.

Differences in tool path sequencing, cutter compensation strategy, and load distribution can shift tolerances by 50–150 microns in plastics or lightweight metals. In OEM environments where statistical process control (SPC) targets Cpk ≥ 1.33 or 1.67, these deviations directly affect capability metrics and downstream assembly performance. Production accuracy is not just about a first article—it is about sustained process control.

How Tool Path Logic Affects Dimensional Consistency

Tool path logic governs cutter engagement angle, radial load, chip evacuation, and thermal buildup. In materials such as aluminum, aggressive radial engagement increases tool deflection, while in plastics like POM or ABS, excessive heat can cause localized deformation. Without compensation strategies embedded in the CNC router program, dimensional variation compounds over batch runs.

Mature programming accounts for material modulus, thermal sensitivity, and feature geometry. Adaptive stepdowns, climb milling strategies, and load-balanced passes help maintain repeatability. A 2–3% improvement in dimensional consistency can significantly reduce inspection frequency and lower rejection rates. For buyers, that translates into fewer assembly misfits, less rework, and reduced downstream disruption.

Programming Decisions That Influence Surface Finish and Fit

Surface finish affects sealing performance, press-fit tolerances, and mating component integrity. In softer polymers, incorrect feed rates may cause tearing; in composites, improper tool selection can cause fiber pullout. CNC router programs control finishing passes, tool speed modulation, and step-over precision that directly influence Ra values and edge integrity.

For example, a poorly optimized finish pass may increase surface roughness from 1.6 µm to 3.2 µm, doubling friction in sliding assemblies. That can trigger premature wear or fit failures. Buyers in OEM manufacturing environments understand that such deviations increase warranty exposure and assembly downtime. Programming optimized for production stability—not just speed—protects functional performance and cost predictability.

Trustbridge Tip: Treat CNC Programming Like a Production System, Not a Shop Task

CNC router programs directly impact dimensional accuracy, cycle time, scrap rates, and compliance. Buyers who assess programming controls the same way they assess injection molding process stability gain better long-term results. Look for documented change management, program simulation validation, and cross-functional review before release. Mature programming discipline signals production maturity. To understand how evaluating manufacturing partners through a systems lens reduces risk, review our partner evaluation guide.

CNC Router Programs and Lead Time Risk

Missed delivery dates carry financial consequences, from expedited freight to line stoppage penalties. Program quality—defined by validation rigor, documentation standards, and repeatability—directly influences how reliably jobs transition from engineering release to production scale.

When programs are unstable or undocumented, scaling from prototype to volume introduces bottlenecks. Mature programming frameworks allow rapid replication across machines and shifts, enabling suppliers to expand capacity without performance loss.

Setup Time, Changeovers, and Program Readiness

Standardized programming systems incorporate unified tool libraries, preset work offsets, digital setup sheets, and probe calibration routines. These controls reduce setup variation across multi-shift operations.

A reduction of even 20–30 minutes per setup can increase weekly throughput capacity by 5–10% in high-mix environments. For procurement teams, that flexibility supports demand surges without renegotiating pricing or accepting extended lead times. Standardized programs also reduce dependency on individual operators, strengthening operational resilience.

How Program Validation Reduces Rework and Delays

Advanced suppliers use simulation software, digital twins, collision detection systems, and first-run validation protocols before cutting material. This proactive validation contrasts sharply with reactive shops that troubleshoot after scrap occurs.

Unvalidated programs can cause tool crashes, part distortion, or extended machine downtime. The hidden cost includes wasted material, lost machine hours, and delayed shipments. Buyers working with validated programming systems experience smoother production ramps and reduced schedule volatility.

CNC Router Programs and Cost Control for Buyers

Total cost of ownership extends beyond piece price. CNC router programs influence tool life, machine utilization, scrap rates, and corrective action cycles. Programming maturity—defined by structured validation, version control, optimization analytics, and continuous improvement review—directly affects long-term cost stability.

Suppliers lacking programming maturity may offer competitive quotes initially, but inefficiencies often emerge after volume production begins.

Cycle Time Optimization and Its Cost Impact

Optimized tool paths eliminate redundant air moves, balance spindle loads, and maintain efficient cutting trajectories. A 10% cycle time reduction across a 20,000-unit annual volume can translate into substantial cost savings and increased available capacity.

However, over-optimization without stability controls can increase tool wear or dimensional variation. Mature suppliers balance efficiency with process capability. For buyers, this balance ensures competitive pricing without sacrificing reliability or capacity planning flexibility.

Scrap Reduction Through Smarter Programming

Programming errors such as incorrect depth compensation, inadequate lead-ins, or failure to accommodate material variability often cause batch scrap events. In prototype runs, scrap may be minimal. In production, a 3% scrap rate across thousands of units compounds into significant cost exposure.

Advanced CNC router programs integrate adaptive feed adjustments and conservative initial passes to control variability. Reduced scrap lowers material waste, inspection labor, and corrective action overhead. Buyers benefit from predictable margins and fewer quality escalations.

Supplier Risk Management and CNC Programming Maturity

Financial strength alone does not guarantee production stability. Programming maturity reflects whether a supplier operates with institutionalized process control or relies on individual expertise.

Programming maturity includes documented standards, revision tracking, simulation validation, and change authorization controls. These elements support operational stability and compliance alignment, reducing systemic risk for buyers.

Identifying Hidden Risks During Vendor Vetting

During vendor vetting, buyers should evaluate whether programs are centrally stored, version-controlled, and linked to part revisions. Questions around backup systems, access control, and approval workflows reveal whether knowledge is institutional or individual.

Suppliers dependent on one programmer present scalability and continuity risk. Documented programming frameworks demonstrate readiness for production growth and personnel transitions.

Why Programming Discipline Belongs in Supplier Scorecards

Programming performance correlates with measurable KPIs such as on-time delivery, defect rates, and corrective action frequency. Recurring dimensional drift often traces back to undocumented program edits.

Integrating programming governance metrics into supplier scorecards elevates evaluation from operational tracking to strategic oversight. For executive stakeholders, programming maturity signals whether a supplier can sustain long-term partnership stability

CNC Router Programs and Production Part Approval Process (PPAP)

In automotive, aerospace, and medical manufacturing, PPAP validation extends beyond dimensional inspection. It confirms that production processes are stable, documented, and repeatable. CNC router programs sit at the center of that verification.

Without structured program control, PPAP approval becomes vulnerable to process drift after initial validation.

Program Control as Part of PPAP Compliance

Version-controlled programs include locked revisions, documented approval signatures, and traceable linkage to engineering drawings and process flow diagrams. Audit exposure arises when uncontrolled edits bypass formal change procedures.

Buyers should confirm that CNC router programs are embedded within documented change management systems, not stored as editable shop-floor files without oversight.

Avoiding PPAP Rejections Linked to Process Instability

Unapproved program changes can alter tool paths, speeds, or offsets, invalidating previously approved capability studies. Resubmissions require new sample runs, additional inspection time, and delayed launches.

These disruptions create administrative burden and cost escalation. Clear cause-and-effect governance—where every program change requires engineering authorization—protects buyers from repetitive approval cycles.

Supplier Risk Management and CNC Programming Maturity

Financial strength alone does not guarantee production stability. Programming maturity reflects whether a supplier operates with institutionalized process control or relies on individual expertise.

Programming maturity includes documented standards, revision tracking, simulation validation, and change authorization controls. These elements support operational stability and compliance alignment, reducing systemic risk for buyers.

Identifying Hidden Risks During Vendor Vetting

During vendor vetting, buyers should evaluate whether programs are centrally stored, version-controlled, and linked to part revisions. Questions around backup systems, access control, and approval workflows reveal whether knowledge is institutional or individual.

Suppliers dependent on one programmer present scalability and continuity risk. Documented programming frameworks demonstrate readiness for production growth and personnel transitions.

Why Programming Discipline Belongs in Supplier Scorecards

Programming performance correlates with measurable KPIs such as on-time delivery, defect rates, and corrective action frequency. Recurring dimensional drift often traces back to undocumented program edits.

Integrating programming governance metrics into supplier scorecards elevates evaluation from operational tracking to strategic oversight. For executive stakeholders, programming maturity signals whether a supplier can sustain long-term partnership stability

Trustbridge Tip: Programming Discipline Starts at Supplier Onboarding

Reducing CNC programming errors is important, but long-term production stability starts much earlier, during supplier onboarding. Buyers who evaluate programming validation processes, version control systems, and PPAP readiness during vendor vetting reduce downstream surprises. Strong onboarding frameworks ensure that CNC router programs are documented, repeatable, and audit-ready before production ever scales. For a deeper look at structured supplier identification and onboarding strategies, explore our resource on building stronger supplier foundations.

Supplier Compliance and Certification Expectations

ISO 13485 and AS9100 demand documented process validation, traceability, and risk-based thinking. CNC router programs must align with these requirements to withstand audit scrutiny.

Programming controls influence device history records, first article inspections, and audit trail integrity.

CNC Programming Practices Under ISO 13485 and AS9100

Certified suppliers should demonstrate program review logs, revision history tracking, and linkage between program versions, part drawings, and inspection reports. Audit visibility extends to how changes are approved and communicated.

Compliance requires operational enforcement, not just documented procedures. Buyers should verify that programming controls are actively implemented across shifts and machines.

Change Management and Program Traceability

Traceability systems tie CNC program revisions to engineering change notices, operator authorization records, and timestamped release logs. Without this chain, parts may be produced under outdated parameters.

In regulated environments, such lapses expose buyers to audit findings or recall risk. Executive teams recognize that strong traceability frameworks reduce compliance exposure and protect brand reputation.

Conclusion

CNC router programs influence statistical capability, delivery reliability, total cost of ownership, and compliance integrity. Buyers who evaluate suppliers solely on equipment and price overlook a primary driver of production stability.

Programming maturity reflects whether a supplier operates reactively or with structured, scalable control. Selecting partners with disciplined CNC programming practices strengthens long-term collaboration, protects margins, and reduces operational uncertainty.

Before awarding your next CNC routing contract, request documentation of program validation procedures, revision control systems, and change management workflows. Review how programs are approved, stored, and audited across shifts.

Adopt an audit mindset during supplier evaluation. The suppliers who can demonstrate programming governance today are the ones most likely to protect your quality, cost, and delivery commitments tomorrow.

Frequently Asked Questions (FAQs)

1. Why are CNC router programs considered a supplier risk factor for buyers?

CNC router programs control tool paths, tolerances, speeds, and sequencing logic. If programs are unstable or poorly controlled, they can cause dimensional drift, scrap, and inconsistent lead times. For buyers, this translates into higher total cost, delivery delays, and potential compliance failures in regulated industries.

2. How do CNC router programs impact PPAP approval and production validation?

PPAP requires documented, repeatable processes. CNC router programs must be version-controlled, validated, and traceable to approved drawings. Uncontrolled program edits after approval can invalidate capability studies and trigger costly resubmissions, delaying production launches.

3. What is “programming maturity” in CNC routing?

Programming maturity refers to structured validation processes, revision control systems, documented change management, simulation verification, and standardized setup procedures. Mature programming reduces variability, improves scalability, and strengthens supplier scorecard performance.

4. How can buyers assess CNC programming capability during vendor vetting?

Buyers should request documentation of simulation procedures, revision control logs, change authorization workflows, and program storage systems. Reviewing how suppliers manage program updates across shifts and machines provides insight into scalability and operational stability.