From PO to Port: The 5 Communication Secrets for Managing Overseas Suppliers

Managing overseas suppliers is far more than a routine administrative task; it's a critical supply chain orchestration challenge. It requires seamlessly coordinating procurement, operations, logistics, quality, and commercial teams across global distances, disparate time zones, and incompatible systems.

When internal coordination fails, the consequences are immediate and severe: purchase orders miss critical cutoffs, shipments are delayed, and operational costs escalate significantly. This communication breakdown introduces massive friction into your supply chain, creating financial risk and damaging vendor reliability

Eliminate these costly disruptions. This essential guide provides five strategic communication protocols you can implement today to achieve operational excellence and enable you to strategically manage and scale every critical supplier relationship.

Why communication is the competitive multiplier

Supply chains that lack timely, accurate information create hidden costs: expediting fees, inventory imbalances, missed launch dates, and reputational damage. Industry research shows a widening gap between aspirations and capability on real-time visibility: 77% of supply-chain decision-makers say real-time visibility is a must-have, but only about 25% actually using it.

That gap creates the practical space where communication practices, not just contracts, make the difference. Leading consultancies are clear: digital capabilities (digital twins, analytics), governance rituals (weekly cadence), and multiparty data sharing are the high-return investments for procurement and operations teams. For example, McKinsey highlights how AI-powered digital twins can unlock end-to-end supply-chain growth and resilience.

Secret 1 - Make the PO a living document: combine structured data + human context

The problem: POs often become static Excel files that sit in an inbox. Logistics, production schedules, and compliance need to evolve after issuance, and if that updated context isn’t attached to the PO, downstream teams (and carriers) act on stale inputs.

Practice: Treat the PO as a living record. Include machine-readable fields (ASIN/SKU, incoterms, target vessel cutoffs, packing instructions, compliance docs) and a short human summary (exceptions, critical tolerances, holds). Use a single source of truth: a cloud PO record linked to the contract and the shipment plan. This reduces clarifying back-and-forth and accelerates decisions. Implementation often means enabling EDI/API integrations from your ERP to supplier portals or TMS platforms.

Secret 2 - Short, predictable cadence beats ad-hoc messages

The problem: Ad-hoc email threads, WhatsApp updates, and last-minute calls create noise and the “who knows what” problem blossoms. Without predictable touchpoints, critical items are missed until it's too late.

The practice: Create a standardized cadence mapped to the PO lifecycle:

PO Issuance Day (T0): Formal PO plus annotated checklist (packing list template, labeling, test reports).

Production Milestone (T+X): Supplier uploads confirmation photos / inspection checklists to portal; QA flags logged.

Pre-Shipment Check (T-72 hours to vessel cutoff): Logistics confirms container availability / carrier pickup ETA.

Port and ETA updates (continuous): Container status updates and a single escalation path for exceptions.

Use a simple RACI for each cadence item: who confirms, who approves, who escalates. Keep the cadence visible in a shared calendar and on the PO record so supply-side and internal teams know exactly when to expect what.

Secret 3 - Invest in visibility, not vanity tech: measurable signals + tied KPIs

The problem: Many companies buy point solutions that produce dashboards but not action. Visibility without tied KPIs becomes “nice to know” rather than “must act.”

The practice: Build visibility for specific decisions. Define the minimal set of real-time signals that change decisions between PO and port: production completion timestamp, container stuffing time, bill of lading issuance, carrier ETAs, customs hold. For each signal, define the action:

If production complete > X hours late → trigger supplier corrective plan and freight rebooking assessment.

If container stuffing delayed → prioritize expedited inspection or next available vessel slot.

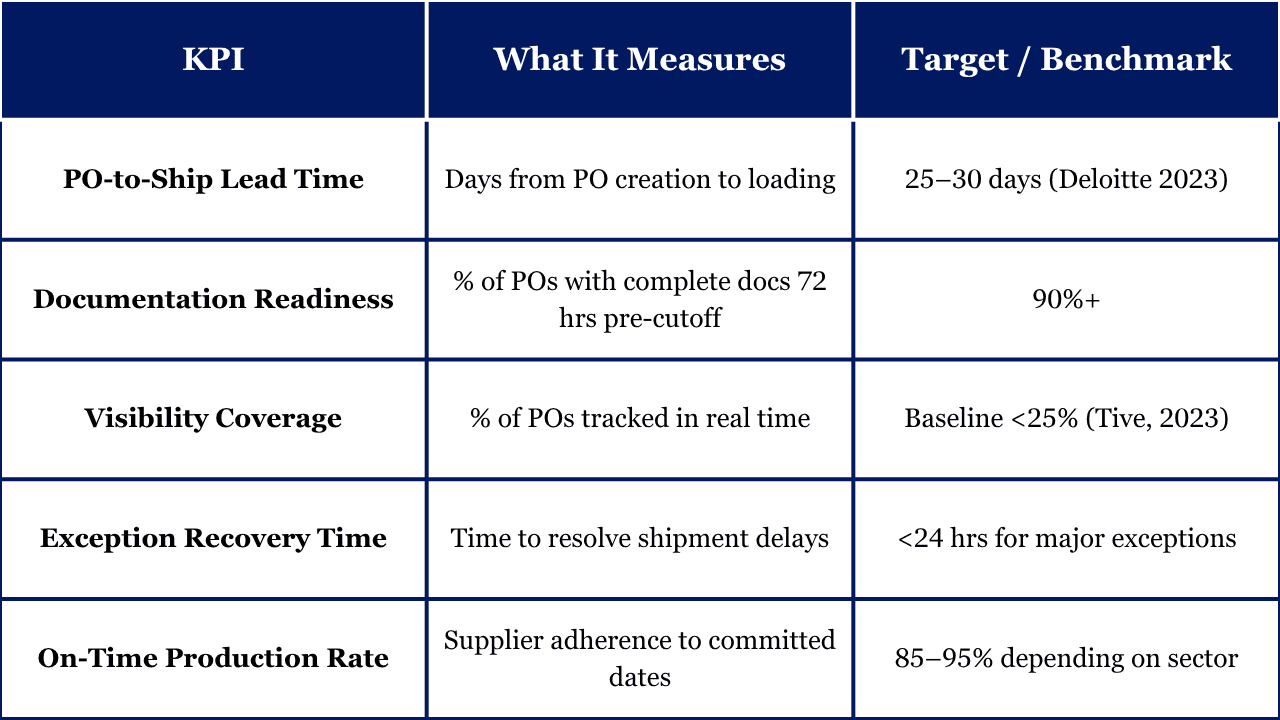

Attach KPIs to those signals (on-time production %, PO-to-ship lead time, % of POs with B/L issued before cutoff). Use measurable thresholds so automated alerts become meaningful escalations.

Secret 4 - Structure exceptions as short playbooks, not long email novels

The problem: When something goes wrong with a failed QC, a missed vessel, a customs hold teams' default to long emails, phone tag, and ad-hoc escalation. That wastes hours when minutes matter.

The practice: Pre-write short “exception playbooks” tied to PO types and risk levels. Each playbook should be a one-page checklist with: trigger condition, immediate action steps (who calls whom), decision authority (who can approve rework or expedited shipping), and containment actions (alternate vendor, partial shipments). Test playbooks with tabletop drills once per quarter.

Examples of playbooks:

Failed incoming inspection: Hold shipment, supplier rework timeline ≤ 72 hrs, prioritized inspection slot.

Missed vessel cutoff: Carrier rebook within 24 hrs; assess cost difference vs expedited air for critical SKUs.

Customs hold: Document checklist (commercial invoice, certificate of origin, packing list), immediate submitter, escalation to customs broker.

Secret 5 - Match the channel to the ask: asynchronous systems for records, synchronous for critical resolution

The problem: Teams use the wrong tool for the job. Urgent negotiations happen by email; audit trails are on chat apps; critical approvals are verbal with no follow-up.

The practice: Adopt a "channel taxonomy" and train teams:

Asynchronous (permanent record): Use supplier portals, ERPs, or ticketing systems for PO records, attachments, invoices, certificates. These are auditable and searchable.

Near-real-time (operational coordination): Use TMS/visibility platforms, integrated EDI, or shared dashboards for shipment status. These push alerts and can be tied to triggers.

Synchronous (escalation and negotiation): Reserve calls/video for exceptions and relationship building — but always summarize the outcome in the PO record or ticket immediately after.

When integrating chat/instant tools, enforce a habit: every discussion that changes dates, quantities, or price must produce a confirmation in the formal system within 24 hours. That rule ensures verbal agreements become enforceable on records.

Why it works: Accenture and other leaders emphasize multiparty connectivity and standards (shared ledgers or APIs) to stitch together these channels into a coherent flow; the goal is one reconciled truth across systems.

Trustbridge Tip: Global manufacturing demands flexibility. One design rarely fits all markets or factories—adapt your specs early to local capabilities and standards. Learn how to manage design variability effectively here.

Practical Stack: Tools + Quick Architecture to Implement in 90 Days

Building an effective supplier communication system doesn’t require overhauling your tech stack it requires sequencing the right steps. Here’s how to roll it out in stages:

Short Term (0–30 Days): Set the Foundation

Start with process clarity before tech.

Map your PO lifecycle and identify where communication gaps occur.

Define a RACI chart — who owns, approves, and escalates at each stage.

Standardize your PO templates to include structured fields (Incoterms, vessel cutoff) and attachments.

Launch a simple cadence schedule (weekly or milestone-based) so updates happen predictably.

Outcome: Every stakeholder knows their role, communication, rhythm, and documentation process.

Medium Term (30–90 Days): Enable Digital Collaboration

Digitize supplier interactions and make status visible.

Set up a supplier portal or shared workspace for uploading POs, invoices, and inspection docs.

Use visibility tags like “production complete,” “packed,” and “loaded on vessel” to track progress.

Configure alerts for recurring risks like missing paperwork or QC delays.

Outcome: Buyers and suppliers work

Long Term (90+ Days): Integrate and Predict

Once workflows stabilize, connect your systems for data flow and forecasting.

Integrate ERP → supplier portal → TMS via API/EDI for seamless PO updates.

Adopt predictive analytics or digital twins to model delays and optimize routes (as highlighted by McKinsey, 2024).

Automate exception routing through a ticketing system like Jira or Asana.

Outcome: End-to-end visibility, faster decisions, and reduced manual firefighting.

Suggested Tech Stack

ERP + Supplier Portal: SAP B1, Oracle NetSuite, or Zoho ERP.

Visibility Tool: Tive for real-time shipment tracking.

Issue Tracker: Jira or Asana for exception playbooks.

Document Storage: DocuSign or OneDrive for audit trails.

Governance and KPIs You Must Track

Strong governance ensures tools deliver measurable outcomes. Focus on a few north-star metrics tied to supplier accountability and lead-time efficiency:

Tie these KPIs to your supplier for scorecards and commercial terms rewarding consistency, while triggering corrective actions for chronic delays.

Outcome: Unified visibility, faster turnaround, and stronger buyer-supplier trust — exactly what Deloitte and Gartner identify as core drivers of resilient global supply chains.

The human side: language, culture, and trust

Communication processes and tools are only as good as the relationships behind them. Invest time in:

Cross-cultural training: Teach procurement and operations on culturally appropriate negotiation and escalation styles.

Quarterly supplier reviews: Make them collaborative present data, propose improvements, and co-invest in capability.

Transparency rituals: Share demand forecasts and production plans when possible. Research and consulting firms (McKinsey) emphasize collaboration and governance to reduce volatility and build resilience.

Quick checklist Operationalize today

Create one living PO template with required machine fields + 3-line human summary.

Establish PO-linked cadence (T0, production milestone, T-72 pre-cut).

Configure automated alerts for top 3 choke points (production complete, stuffing, B/L issued).

Draft 3 exception playbooks (failed QC, missed vessel, customs hold) and circulate.

- Start supplier scorecard with two KPIs: on-time production % and documentation completeness.

Closing: turn predictable communication into predictable delivery

In the end, managing overseas suppliers effectively isn’t just about sending a purchase order and waiting for goods to arrive; it’s about building a system of clarity, consistency, and collaboration that bridges every time zone and touchpoint. From the first PO draft to the container leaving the port, every communication, update, and confirmation plays a role in shaping outcomes. When buyers establish structured communication rhythms, transparent data flows, and measurable performance standards, they don’t just prevent delays they set a new operational standard for trust and predictability. The real advantage lies in transforming supplier management from a reactive process into a proactive partnership. By investing in clear frameworks, digital visibility, and strong governance, buyers create supply chains that can move faster, recover smarter, and adapt to change with confidence turning every supplier relationship into a strategic asset rather than a risk to be managed.

Trustbridge Tip: Sourcing issues often start with misalignment. Before issuing a PO, ensure your teams agree on cost, lead time, and quality goals. Learn how to fix common sourcing mistakes here.

Frequently Asked Questions

Q1: What’s the single biggest communication improvement that reduces late shipments?

Define and enforce a pre-shipment readiness checkpoint (T-72 hours) where documentation, packing, and vessel status are confirmed. This single meeting or portal checkpoint reduces last-minute surprises.

Q2: Should we force suppliers onto our ERP?

Where possible, require machine-readable uploads (EDI/API) for key fields; but start with a light supplier portal and escalate to ERP integration for high-volume or high-risk suppliers.

Q3: How do I measure ROI on visibility tools?

Measure reduction in expedited freight costs, decrease in average exception recovery time, and improvement in PO-to-ship lead time. Those three metrics translate directly to cost savings.

Q4: Is blockchain required for transparent supplier communication?

Not required. Blockchain or shared-ledger tech can help multi-party trust and traceability, but the immediate ROI often comes from consistent governance and reliable telemetry. Accenture highlights blockchain as a useful enabler for multiparty trust—but it’s one of several tools.