Designing for Global Supply Chains:

How Specs Change Across Borders

Global supply chains are the backbone of modern manufacturing, connecting design teams, suppliers, and customers across continents. But while globalization opens opportunities for cost savings, scalability, and innovation, it also introduces new risks. Part quality, pricing, and compliance can vary drastically between domestic and international suppliers. A design that works perfectly in the U.S. may fail in Asia due to differences in standards, material grades, or local manufacturing processes.

Understanding these isn’t optional, it’s essential for any company looking to scale globally. In this blog, we’ll explore how specifications change across borders, where common misalignments occur, and how to build a design-for-manufacturing (DFM) strategy that avoids costly rework and delays.

How Globalization Affects Part Quality, Pricing, and Risk

Globalization has enabled companies to source from multiple regions, often balancing cost advantages with increased complexity. For instance, a component produced in Southeast Asia may be significantly cheaper due to lower labor costs, but hidden expenses can creep in like longer lead times, higher shipping fees, or unexpected rework caused by spec misalignment.

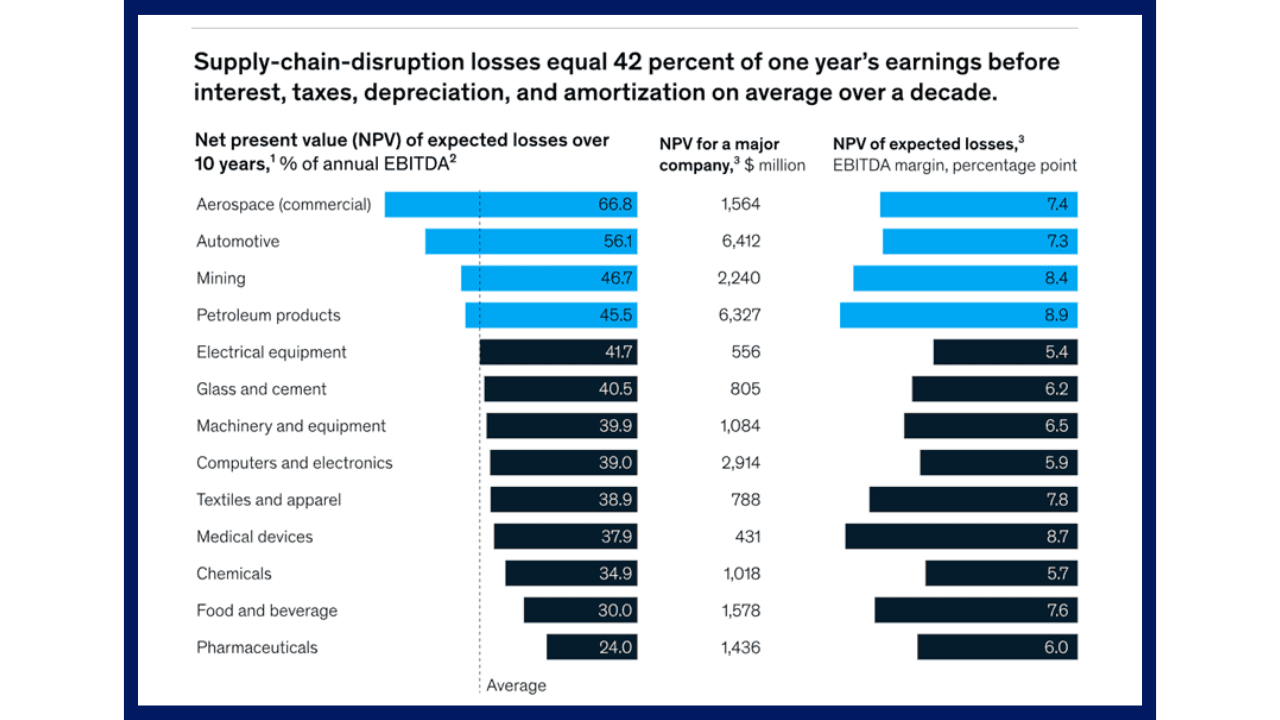

Quality also varies: a “standard” fastener sourced in Europe may not meet the same tensile strength as its counterpart from another region unless standards are explicitly specified. Risks compound when suppliers interpret drawings differently or substitute materials without approval. According to a McKinsey report, supply chain disruptions cost companies an average of 42% of one year’s EBITDA over a decade—underscoring why specs must be globally robust.

Trustbridge Tip: Simplify your part design to cut manufacturing costs — less complexity means fewer setups, lower labor, and faster production. Read the full blog to learn more.

Why Domestic Specs Don’t Always Translate Overseas

Domestic specifications often reflect local norms, material availability, and measurement systems. When a U.S. company shares a drawing that assumes imperial units, overseas suppliers accustomed to the metric system may misinterpret dimensions. Similarly, what counts as “standard tolerance” in one country could require specialized tooling elsewhere.

Without clarification, suppliers may make assumptions, leading to rework, longer timelines, and quality issues. For example, surface finishes common in North America may not be standard in South Asia unless explicitly detailed. Ensuring that documentation is globally clear avoids the trap of “domestic-first thinking” that doesn’t translate in international contexts.

What Changes Across Borders

Metric vs. Imperial Complications

The clash between metric and imperial units is one of the most common and preventable supply chain challenges. A simple error, such as mistaking inches for millimeters, can derail an entire production batch. NASA famously lost the Mars Climate Orbiter due to a similar mismatch in unit systems, costing $327.6 million.

To avoid this in manufacturing, engineering teams should always provide dual-dimensioned drawings, with primary and secondary units clearly defined. Adding a tolerance chart and notes eliminates ambiguity. This upfront effort reduces supplier misinterpretations and ensures precision across geographies.

Supplier Misinterpretation Risks and Rework Implications

Language barriers, technical assumptions, and different cultural approaches to problem-solving often cause suppliers to interpret specs differently. For example, if a drawing lacks clear instructions on allowable surface imperfections, one supplier may polish aggressively while another might ship parts with visible marks. Both may claim they followed the “spec.”

Investing in supplier communication protocols — like annotated drawings, video walkthroughs, and first-article approvals minimizes these risks.

Material Substitutions and Regional Availability

Material availability differs drastically across regions, and substitutions are common. For example, Aluminum 6061 is widely used in the U.S., while Aluminum 6082 is often the equivalent in Europe. Similarly, stainless steel grades like 304 are standard in global markets, but suppliers in some regions may default to lower-cost alternatives like 201 unless otherwise stated.

If substitutions are not pre-approved, they can impact corrosion resistance, machinability, and compliance. By documenting acceptable equivalents and their limits, design teams can control variability while enabling flexibility.

Local Manufacturing Capabilities and Limitations

Manufacturing capacity and technical expertise vary worldwide. In some regions, high-precision machining or tight tolerances may not be economically feasible due to limited tooling or higher costs. For instance, a supplier may not support minimum wall thicknesses below a certain threshold, leading to design adjustments.

Understanding these constraints early allows design engineers to balance cost with capability. Pre-production sampling, supplier audits, and transparent dialogue about tooling capacity can prevent downstream issues.

Trustbridge Tip: Looking to cut costs without compromising performance? Discover how Trustbridge’s redesign services help optimize your products for efficiency, durability, and global market success. Explore Redesign Services.

Compliance and Logistics

Certifications: CE, RoHS, UL, REACH

Compliance is not universal—what satisfies U.S. regulations may fail in Europe or Asia. Certifications like CE (EU safety), RoHS (hazardous substances), UL (U.S. safety), and REACH (EU chemicals) carry different weight depending on the destination market. Missing a certification doesn’t just cause delays—it can bar entry into an entire region.

Designing for global supply chains means identifying which certifications matter most to your target markets. For example, a consumer electronics product destined for Europe must prioritize CE and RoHS, while the U.S. market may emphasize UL. Aligning specs with these frameworks ensures smoother compliance checks.

Customs, Labeling, and Packaging Needs

Beyond part quality, customs clearance depends heavily on labeling and packaging accuracy. Countries impose strict rules on how goods are classified, declared, and packaged. A mislabeled shipment can be held at customs for weeks, incurring demurrage charges.

Special packaging may also be required for fragile items, batteries, or dangerous goods. Lithium-ion batteries, for instance, must comply with UN3480 or UN3481 standards for transport. A proactive packaging strategy not only protects parts but also ensures legal compliance.

Shipping Stress and Environmental Durability

Global shipments expose parts to humidity, vibration, and temperature swings. A component designed for local use may fail when subjected to weeks of ocean freight. Packaging therefore becomes part of your DFM strategy—not an afterthought.

Consider humidity barriers, shock-absorbing inserts, or corrosion inhibitors for long-haul shipments. Packaging that anticipates environmental stress reduces warranty claims and builds customer trust.

Best Practices

Multi-Market-Ready Drawing Sets

Creating drawing sets that are globally adaptable is essential. This includes dual units, alternate tolerances, and notes about acceptable material substitutions. Engineering teams should aim for clarity, redundancy, and zero room for guesswork.

Clearly Specifying Alternate Materials, Units, and Tolerances

Instead of leaving substitutions to chance, engineers should proactively specify acceptable equivalents. For example: “Aluminum 6061 or 6082 acceptable; tolerance ±0.1mm unless otherwise noted.” Such documentation reduces ambiguity and speeds production.

Documenting Acceptable Substitutions

Documentation is critical for auditability and repeatability. By cataloging pre-approved substitutions, teams enable suppliers to adapt without compromising quality. This also helps during scaling when multiple suppliers are engaged.

Pre-Approving Material and Finish Equivalents

Surface finishes, coatings, and treatments vary globally. Pre-approving equivalents (e.g., zinc plating vs. nickel plating) ensures both cost-effectiveness and durability. These approvals should be tested and validated before mass production.

Trustbridge Tip: Learn the top 10 tips for identifying and onboarding the right suppliers, helping buyers streamline procurement, reduce risk, and build a reliable, future-ready supply chain. Read the full guide here.

Conclusion

Designing for global supply chains isn’t just about cost, it’s about foresight. Specs that work domestically rarely translate seamlessly overseas. By anticipating differences in units, materials, compliance, and logistics, companies can avoid costly pitfalls and accelerate time-to-market. A global-ready design mindset, rooted in clarity, documentation, and proactive approval enables businesses to build resilient supply chains that thrive across borders.

Ready to move your procurement from spreadsheets to strategy? AI is no longer optional — it’s the backbone of modern buying. Empower your procurement team with intelligent sourcing, real-time spend visibility, and smarter decision-making. Visit Trustbridge.pro to explore buyer resources, case studies, and solutions designed to help procurement professionals lead with confidence.

Frequently Asked Questions (FAQs)

Q1. Why do engineering specs need to change across different countries?

Because material availability, measurement systems, certifications, and manufacturing capabilities vary globally. What works domestically may not meet compliance or feasibility standards overseas.

Q2. How can I prevent supplier misinterpretation of my design specs?

Provide dual-dimensioned drawings, detailed tolerance notes, and pre-approved material substitutions. Using annotated diagrams and first-article approvals also helps reduce rework.

Q3. What are the biggest compliance risks in global supply chains?

Missing certifications like CE, RoHS, UL, or REACH, incorrect labeling, and improper packaging for customs or dangerous goods are the most common issues that cause costly delays.

Q4. How can Trustbridge support companies designing for global supply chains?

Trustbridge helps streamline product design, validate material and finish substitutions, and align specs with regional compliance all while reducing costs and improving performance.