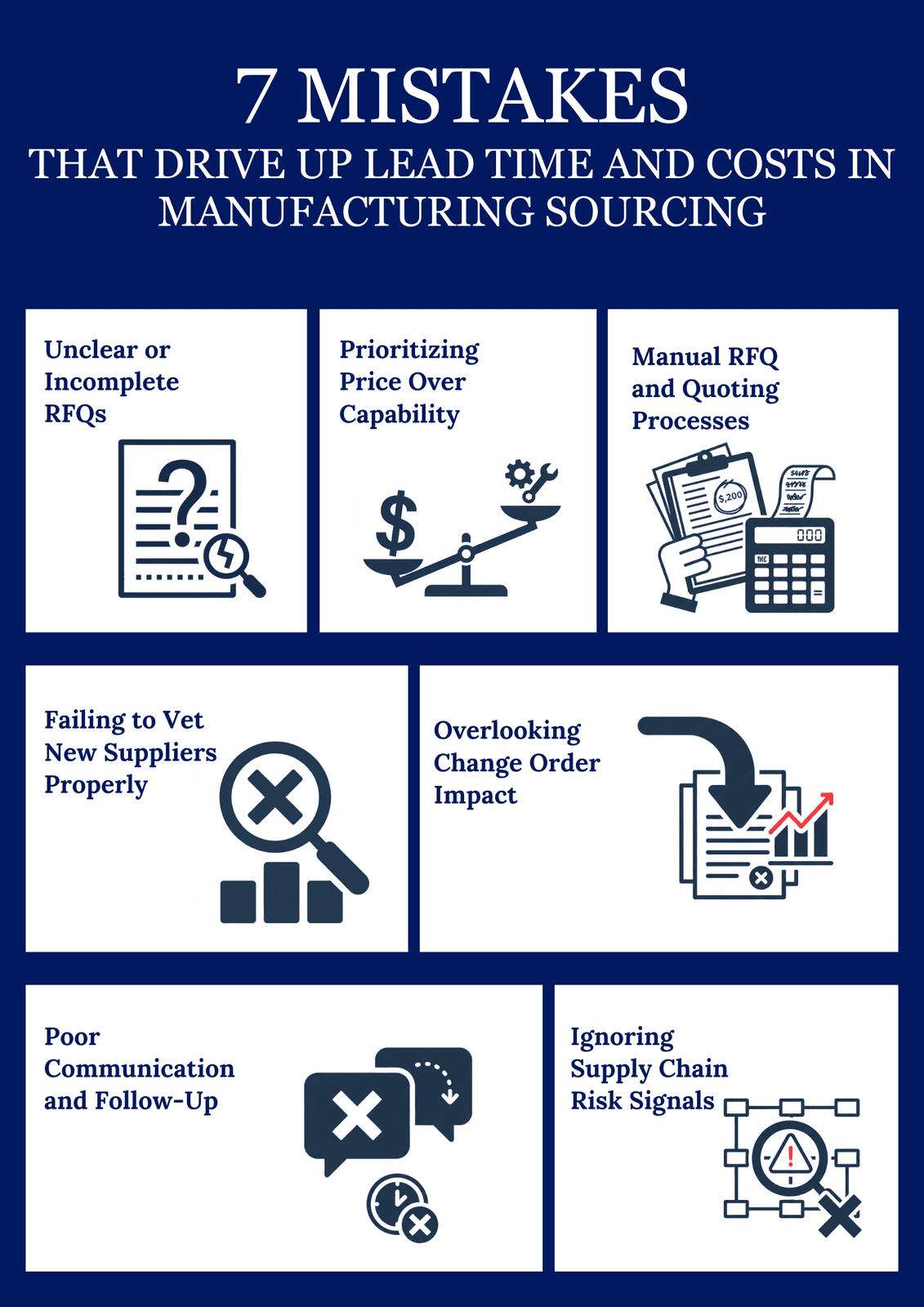

7 Mistakes That Drive Up Lead Time and Costs in

Manufacturing Sourcing

Procurement isn't just about getting the best price anymore it's about speed, agility, and flawless execution. In today's hyper-competitive manufacturing world, the pressure on sourcing professionals is intense: deliver results faster, manage tighter budgets, and ensure your suppliers perform perfectly, every time. It's a tough gig, and frankly, even the most seasoned buying teams occasionally trip up. While we often think of shiny new tech as the solution to all our woes, the biggest headaches in sourcing rarely come from a lack of digital tools. More often, the culprits are basic, avoidable missteps: a missed detail, a clumsy email exchange, or just a simple lack of consistent process. These quiet mistakes the silent killers of efficiency are what truly balloon lead times, unnecessarily drive-up costs, and can even sour vital supplier relationships.

We're going to dive deep into the seven most common sourcing traps that buyers fall into. By recognizing these fundamental mistakes and understanding exactly how to fix them you can reclaim lost time, safeguard your budget, and significantly boost your credibility across the entire supply chain.

1. Unclear or Incomplete RFQs

For buyers, an unclear or incomplete Request for Quotation (RFQ) is one of the most damaging starting points in sourcing. When specifications are vague or incomplete, suppliers are forced to guess. That guesswork leads to misquotes, delays, and mismatched expectations that ripple through production. Even seasoned suppliers can’t deliver accurately if they don’t fully understand what’s required. The root causes are often internal rushed documentation, inconsistent communication between engineering and procurement, or a lack of a standardized RFQ template. These factors create confusion, resulting in multiple clarification rounds and wasted cycle time.

The fix is to treat your RFQ as the foundation of supplier success. Build a detailed template that covers everything: material specs, tolerances, order volumes, quality standards, packaging, labelling, and delivery timelines. Think of it as a “contract preview” the clearer your RFQ, the fewer surprises later. A comprehensive RFQ doesn’t just save time; it builds supplier confidence, accelerates response rates, and sets the stage for a partnership rooted in trust and precision.

2. Prioritizing Price Over Capability

Procurement teams are under constant cost pressure, and it’s easy to be tempted by the lowest bidder. But the cheapest quote rarely represents the lowest total cost of ownership. Suppliers who underquote often cut corners on materials, labour, or process quality leading to rework, delays, or compliance issues that cost far more in the long run. Buyers who prioritize capability over price protect their production schedules and product integrity. A capable supplier brings consistency, scalability, and quality assurance critical attributes that can’t be captured in a price tag.

Evaluate suppliers holistically. Check for certifications like ISO 9001 or IATF 16949, review production capacity, examine quality control systems, and ask for client references. Paying slightly more for the right supplier translates into reduced operational risk, fewer change orders, and sustainable savings.

Trustbridge Tip: Avoiding design failure starts with clarity and collaboration. Discover how misaligned expectations and vague requirements can derail your product—and how to fix them before they cost you time and money. To learn how to streamline your design process and avoid common pitfalls, read the full blog here.

3. Manual RFQ and Quoting Processes

Many buyers still rely on manual sourcing workflows emailing RFQs, tracking responses in spreadsheets, and comparing quotes by hand. While manageable at small scale, this approach breaks down as sourcing volume grows. Procurement teams can lose up to 40% of their time to repetitive admin work, slowing down the entire process. Manual systems lead to missed follow-ups, inconsistent data, and delayed decisions. Important nuances like payment terms, lead time comparisons, or unit economics often get lost. Worse, fragmented email threads make it easy for key details to slip through the cracks.

By adopting digital RFQ management tools, buyers can centralize communication, automate reminders, and instantly compare proposals side by side. Automation not only accelerates quote turnaround but also creates a structured audit trail for accountability and performance tracking.

4. Failing to Vet New Suppliers Properly

Under deadline pressure, buyers sometimes onboard new suppliers hastily skipping proper due diligence. This can expose organizations to major risks: subpar quality, delivery failures, compliance breaches, or even fraud. Effective supplier vetting should go far beyond collecting certificates. Buyers need to validate production capacity, financial stability, quality management systems, and customer references. This process doesn’t have to be slow, but it must be thorough.

Modern supplier verification platforms can increasingly help automate these checks, flag inconsistencies, and maintain digital records of compliance. The goal is to move fast, but not recklessly. A 15-minute vetting shortcut today can turn into a three-week production delay tomorrow.

5. Overlooking Change Order Impact

In dynamic manufacturing environments, change is constant. Engineering change orders (ECOs) whether a tweak in design, material, or tolerance are common. But when buyers fail to manage these changes properly, the result is chaos across teams and suppliers. Every post-RFQ modification triggers a chain reaction: suppliers must recalculate costs and lead times, procurement must resend updated RFQs, and production plans must be re-synced. A single oversight, like not updating one vendor on a spec change can cause production stalls, rework, and cost overruns.

Common pitfalls include sending revised specs to only some suppliers, using inconsistent file names, or assuming a supplier can adapt without additional cost or delay. The best buyers mitigate this risk by creating formal change management workflows. Every spec update should be documented, version-controlled, and communicated through a single source of truth. This discipline prevents downstream confusion and keeps suppliers aligned.

6. Poor Communication and Follow-Up

Sourcing is a relationship-driven function and silence is expensive. Many procurement bottlenecks originate not from suppliers but from buyers who respond too slowly or communicate too vaguely. When supplier questions go unanswered for days, or when feedback loops are unclear, delays compound quickly. Important context gets buried in long email chains, internal teams work in silos, and no one knows which supplier is operating with the latest information.

Poor communication erodes trust and predictability. The best procurement teams establish structured communication frameworks dedicated RFQ dashboards, response timelines, and escalation paths. Clarity and responsiveness transform suppliers into collaborators rather than vendors.

Trustbridge Tip: Silent delays in your supply chain can quietly erode margins and disrupt timelines. Smart buyers stay ahead by proactively identifying hidden bottlenecks and building transparency into every stage of their sourcing strategy. Want to spot and solve these silent setbacks before they cost you? Read the full blog here.

7. Ignoring Supply Chain Risk Signals

Too many sourcing teams operate reactively, addressing supplier issues only after production is already affected. By the time a shipment is delayed, or a batch fails inspection, options are limited and expensive. Instead, forward-looking buyers actively monitor supplier performance for early warning signs: slower RFQ responses, fluctuating lead times, missed SLAs, or inconsistent communication. These signals often surface weeks before a disruption.

Building a performance dashboard even a simple one can turn weak signals into actionable insights. Tracking metrics like quote turnaround time, delivery accuracy, and quality incidents gives procurement teams a clear picture of supplier reliability. This proactive approach gives buyers leverage. They can redistribute orders, identify backup suppliers, or escalate issues internally before they escalate in production. In an era of fragile global supply chains, early detection isn’t optional — it’s a competitive edge.

Trustbridge Tip: Struggling with sourcing mistakes that stall your manufacturing success? You're not alone and you're not stuck. Learn why sourcing goes wrong and how to fix it with proven strategies from the experts. Explore the insights now and start building a smarter, more resilient supply chain.

Closing Thoughts

For modern manufacturing buyers, sourcing excellence is no longer about price negotiation alone. It is about building systems, relationships, and visibility that make procurement a competitive advantage rather than a bottleneck. The best organizations recognize that sourcing is not a back-office function but a strategic driver of profitability, resilience, and innovation. When buyers invest in process discipline, every decision becomes data-backed and traceable. When they prioritize supplier collaboration over short-term savings, they build long-term trust that pays off in reliability and faster time-to-market. And when they integrate digital tools to automate routine tasks, procurement teams can focus their energy on strategic analysis, risk management, and supplier development instead of paperwork.

Excellence in sourcing comes from combining precision with flexibility — knowing when to standardize processes and when to adapt. It requires ongoing communication between engineering, procurement, and suppliers to ensure that every quote, specification, and timeline aligns with production goals.

Frequently Asked Questions (FAQs)

1. Why do manufacturing buyers often struggle with sourcing despite using modern tools?

Even with advanced platforms, many sourcing challenges stem from basic process mistakes — unclear RFQs, poor supplier vetting, manual workflows, and weak communication. Tools can speed processes, but without disciplined practices, inefficiencies and delays persist.

2. How can buyers reduce lead time and costs when sourcing suppliers?

Buyers can streamline sourcing by creating clear, standardized RFQs, evaluating suppliers holistically beyond price, automating manual workflows, and proactively managing change orders and supply chain risks. Consistent communication with suppliers also ensures faster and more accurate responses.

3. What role does supplier vetting play in sourcing efficiency?

Proper supplier vetting ensures reliability, quality, and compliance. By checking production capacity, financial stability, certifications, and references upfront, buyers can avoid costly delays, quality issues, and unexpected risks in production.

4. How can buyers proactively manage risks in the supply chain?

Buyers can track early indicators such as delayed RFQ responses, inconsistent lead times, or communication gaps. Using dashboards and performance metrics to monitor supplier activity allows procurement teams to address potential disruptions before they impact production.