How to Calculate Machining Costs for CNC Machines

In many CNC machining projects, suppliers are often involved only after the design and material decisions are already finalized. By the time the supplier reviews the drawings and specifications, inefficiencies may already be built into the job, materials that are difficult to machine, part geometries that require unnecessary multi-axis setups, or missing details that lead to repeated clarification. These issues can appear minor at first, but they often lead to longer lead times, increased machining costs, and communication gaps between the buyer and the supplier.

This doesn’t just slow production; it can disrupt project flow and confidence. Suppliers may need to backtrack by adjusting fixtures, re-evaluating feasibility, or requesting revised drawings while still being expected to meet deadlines. Without early alignment, even straightforward CNC machining jobs can become more time-consuming, more expensive, and more stressful than they need to be for both sides.

This blog takes a supplier-first perspective to help avoid these challenges from the beginning. We’ll discuss how early material selection impacts machining efficiency, why proactive fixture planning can significantly reduce cycle time, and how clear communication during the design phase prevents costly revisions later. The goal is to show that suppliers are not just service providers; they are strategic partners. When their expertise is considered early, CNC machine becomes smoother, faster, and far more cost-effective for everyone involved.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a manufacturing method where computer-guided tools automatically shape parts from metal, plastic, and composite materials. CNC technology allows precise, repeatable, and scalable production, making it widely used in aerospace, automotive, industrial equipment, consumer products, and prototyping. Modern CNC machines such as milling centers, turning lathes, and multi-axis machining systems operate based on digital programming (G-code). Once programmed and set up, the machine executes cutting paths with high accuracy, significantly reducing manual intervention. To ensure profitable production and accurate customer quotations, it is essential to understand how machining costs are calculated.

Key Factors That Influence CNC Machining Costs

Several variables shape the final price of a CNC-machined component, and understanding these factors helps achieve more accurate forecasting, better supplier evaluations, and stronger cost control. The final machining cost is never dependent on a single input; rather, it is the result of how material choice, part geometry, machining strategy, and shop capability interact. By analyzing each factor thoughtfully, companies can identify where efficiencies can be gained and where strategic adjustments can reduce unnecessary spending without compromising quality.

1. Material Selection

Material choice plays a significant role in determining machining cost because different materials behave differently under cutting conditions. Soft and free-machining materials like aluminum, brass, and certain plastics generally allow faster cutting speeds, smoother chip removal, and longer tool life, which reduces overall machine time and consumable usage. Harder materials such as stainless steel, tool steels, and titanium require slower feeds, specialized cutting inserts, and frequent tool replacements. These factors not only increase machining time but also raise tooling costs and energy consumption. Additionally, some materials generate higher scrap rates or require pre- or post-processing treatments, both of which further contribute to the total cost per part.

2. Part Geometry and Complexity

The design and complexity of a part heavily influence machining effort. A simple rectangular block with basic holes and faces requires minimal setup and straightforward toolpaths, keeping machining time efficient. However, when the part includes deep cavities, tight internal radii, thin walls, undercuts, or intricate 3D contours, the machine must operate more slowly and deliberately to maintain accuracy and avoid part deformation. Complex parts may also require multiple setups or even different machines, such as moving from a mill to a lathe or adding a secondary 5-axis finishing operation. Each added complexity not only increases machining time but also raises programming and quality inspection effort.

3. Machine Time

Machine time directly determines a large portion of the machining cost because CNC machine shop rates are typically billed hourly. The cycle time required to produce one part depends on the toolpath strategy, feed rates, spindle power, depth of cut, and complexity of tool changes. A longer cycle time means the machine is occupied for extended periods, reducing the shop’s production capacity and increasing per-unit cost. Machine time includes roughing, finishing, and any secondary machining operations required to meet tolerances or surface finish requirements. Therefore, optimizing toolpaths, minimizing empty travel, and selecting appropriate cutting strategies are key levers for cost optimization in CNC production.

4. Labor and Technical Expertise

Labor contributes to machining cost beyond just hands-on time. Skilled machinists are responsible for programming CNC toolpaths, preparing fixtures, adjusting offsets, securing workpieces, inspecting parts, and monitoring tool wear throughout a production run. Parts requiring tight tolerances, specialized inspection documentation, or precision-grade surface finishes demand more technician involvement, increasing labor time. Furthermore, if a part requires frequent setup changes or small-batch manufacturing, the proportional labor cost becomes even higher. Shops with highly experienced machinists may have higher hourly labor rates, but their expertise often reduces errors and machining inefficiencies, ultimately improving overall productivity.

5. Tooling, Fixtures, and Maintenance

Tooling cost includes cutting inserts, drill bits, end mills, collets, fixtures, and custom work holding devices. Complex or hard materials wear tools more quickly, increasing replacement frequency and consumable cost. Some parts require custom fixtures or precision clamps to achieve stability during machining, and these fixtures must be designed, manufactured, and occasionally modified. Maintenance also influences cost, as machines need calibration, lubrication, and replacement of spindles and mechanical components over time. A shop with well-maintained machines and high-quality tooling generally delivers better surface finish and accuracy but must also factor those ongoing maintenance investments into per-part pricing.

6. Overhead and Facility Expenses

Beyond direct machining activities, operational overhead forms an essential portion of CNC manufacturing cost. This includes electricity, coolant and lubricant usage, machine depreciation, shop floor rent, climate control systems, software subscriptions, inspection equipment, and administrative support. These costs do not vary significantly from part to part, so shops distribute them across production volumes using overhead allocation rates. In high-volume production, overhead is spread thinly and reduces the cost per unit. However, for low-volume or prototype work, overhead allocation per part tends to be higher. Efficient facility planning and stable production scheduling play a major role in managing and optimizing overhead cost impact.

Estimating Material Cost

Determining Material Quantity

To accurately estimate the material cost for a CNC- component, it is essential to determine how much raw material is required before machining starts. CNC parts are typically cut from stock such as bars, billets, plates, or cast blocks, and the initial block size must always be slightly larger than the final part dimensions to allow for machining allowances, clamping, and finishing. This means the material purchased often exceeds the final net weight of the finished part. The determination of required material quantity usually begins with analyzing the part’s geometry and selecting the most suitable stock form. For example, cylindrical parts are commonly machined from round bar stock, while prismatic parts may require rectangular plate or block stock. Once the appropriate form is chosen, engineers calculate the required stock dimensions by adding tolerances and machining allowance to all critical surfaces. This is especially important for precision surfaces that may need multiple finishing passes.

Another factor to consider is scrap rate, the percentage of material that will become chips, offcuts, or unusable remnants. Hard-to-machine metals, intricate part shapes, or parts requiring many finishing operations often create higher scrap volumes. If the part is produced in batches, planning for full sheet or bar nesting improves efficiency; however, for low-volume batches or prototypes, the shop may have to purchase more material than is ultimately used. Therefore, the estimated material quantity is usually calculated as:

Required Material Quantity = (Stock Size Needed per Part × Number of Parts) + Scrap Allowance

Understanding quantity accurately helps avoid under-ordering or excessive material waste, both of which directly influence cost and lead time.

Material Unit Cost

Once the required quantity is known, the next step is identifying the material unit cost. This cost refers to the price of the raw material per unit (per kilogram, per pound, per meter, per sheet, etc.). Unit cost depends on several market and specification-based variables. Common metals like 6061 aluminum and mild steel are widely available and competitively priced, while aerospace-grade titanium, medical-grade stainless steels, or engineered polymers may cost significantly more due to performance requirements, certification needs, or limited sourcing.

In addition to base market price, CNC shops consider several hidden cost components when determining the actual unit cost applied in the quote. These include:

- Material grade and specification requirements (e.g., aerospace, defense, food-safe compliance)

- Supplier reliability and lead time (fast delivery often costs more)

- Material finishing requirements (anodizing, coating, heat treating)

- Minimum order quantities (especially for specialty alloys or rare plastics)

The unit cost is often affected by market fluctuations driven by commodity pricing, global demand, and supply chain conditions. For example, price variations in aluminum and stainless steel are common due to global manufacturing cycles and energy cost changes. Shops typically maintain updated supplier quotes or long-term agreements to stabilize cost estimations.

Material unit cost is generally calculated as:

Material Cost = Required Material Quantity × Material Price per Unit

If additional certification, traceability documentation, or inventory holding costs are required, small surcharges may be added. This ensures that the material cost truly reflects the resources necessary to obtain and verify the raw input for the machining process.

Calculating Labor Cost

Labor cost represents the human effort required to transform a raw material into a finished CNC-machined component. This includes activities before, during, and after machining. The machinist or technician must program the toolpaths, configure the machine setup, secure the workpiece, perform trial runs, and validate dimensions through inspection. After machining, the part may require secondary operations such as deburring, surface finishing, cleaning, and packaging. All of these contribute to total labor hours. Labor cost is determined by multiplying the labor hourly rate by the number of labor hours required to complete the part. The number of hours varies depending on the complexity of the design, the number of setups involved, the precision required in tolerances, and the level of inspection or compliance checks needed. When organizations streamline workflows, reduce unnecessary setups, or standardize machining procedures, labor hours are minimized, resulting in more efficient production and lower overall cost. In essence, labor cost increases with complexity and decreases operational efficiency.

Labor Cost = Labor Hourly Rate × Total Labor Hours

Determining Machine Time Cost

Machine time cost reflects how long the CNC machine operates to produce each unit and is often one of the most influential cost factors. The machine time cost is calculated by multiplying the machine’s hourly rate by the total cycle time in hours. The machine’s hourly rate itself is influenced by several underlying factors such as the cost of machine ownership or lease, maintenance schedules, calibration needs, energy consumption, coolant and lubricant usage, and even the allocated cost of floor space within the facility. Additionally, the depreciation of the machine over its lifecycle is spread across the number of hours it is used to produce parts, further shaping the hourly cost. When a component requires multiple tool changes, slow spindle speeds due to material hardness, or complex multi-axis movements, the cycle time increases, directly raising the cost per unit. Conversely, optimizing toolpaths, selecting efficient cutting strategies, or improving fixturing to minimize repositioning can reduce machine time. Therefore, faster and more efficient machining operations always translate into lower cost, while slower operations driven by part complexity or hard-to-machine materials result in higher expense.

Machine Time Cost = Machine Hourly Rate × Cycle Time (in hours)

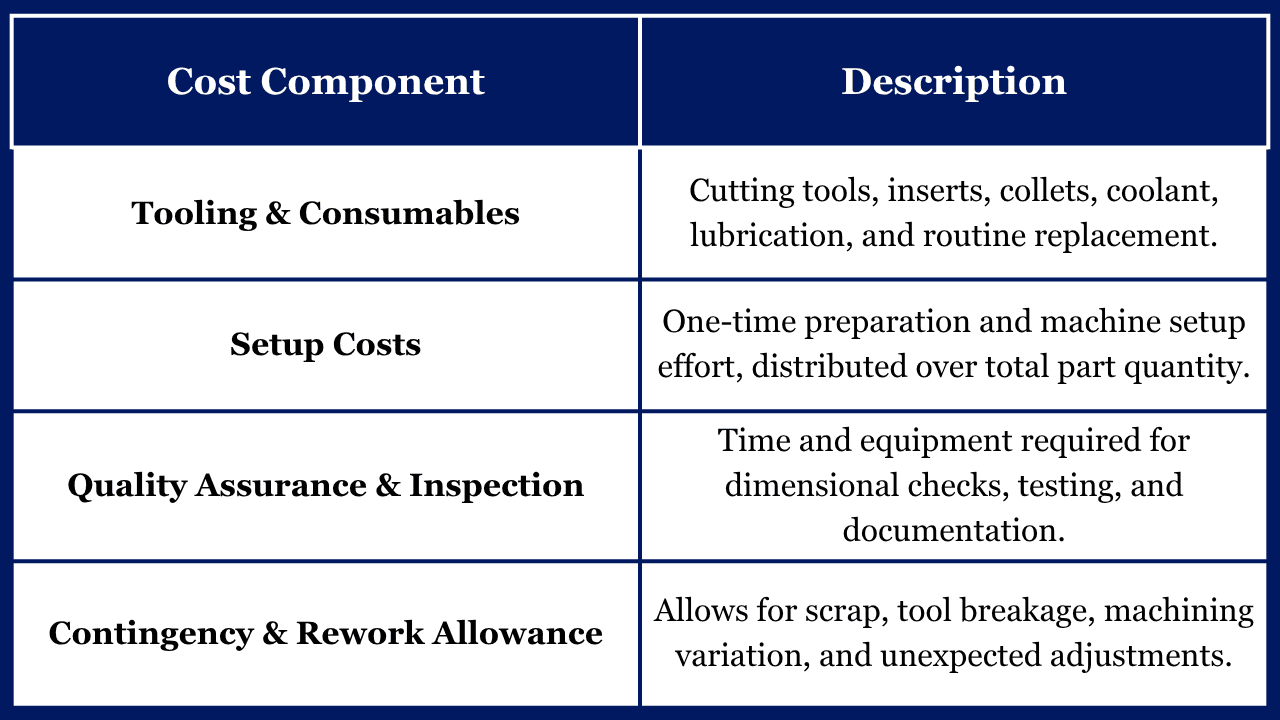

Tooling, Fixtures & Consumable Costs

Tooling and fixturing represent a recurring cost that directly influences the per-part machining price. Cutting tools such as end mills, inserts, drills, and reamers gradually wear out during production, especially when machining harder materials. When a tool reaches its wear limit, it must be replaced, which adds to the consumable cost of each job. Additionally, some projects require custom jigs or fixtures to securely hold the workpiece, particularly when working with irregular shapes or multi-axis machining. While the fixture may be built once, its cost is amortized across the total number of parts produced. Consumables like coolant, lubricants, collets, tool holders, and machine accessories also contribute to ongoing operational cost. As part complexity or production volume increases, the cumulative cost of tooling and consumables tends to rise, making efficient toolpath planning and optimized cutting conditions essential for cost control.

Overhead Allocation Method

Beyond direct machining and labor expenses, overhead costs play a significant role in the final quoted price of a CNC-machined part. Overhead accounts for the facilities that support production, such as electricity usage, machine depreciation, floor space, climate control, administrative staffing, inventory management, and software licensing. Because overhead does not belong to a single job, shops use allocation models to distribute these costs across machine hours or per-part output. A higher-precision shop with advanced equipment may have a higher hourly overhead rate than a general job machine shop, reflecting its greater infrastructure investment. By allocating overhead accurately, CNC shops ensure that pricing remains sustainable, machinery is maintained on schedule, and production capacity is utilized efficiently. Proper overhead allocation supports long-term operational stability and ensures that machining work remains profitable.

Additional Costs to Consider

Final Machining Cost Formula

A commonly used formula to estimate the final per-part machining cost is:

Final Machining Cost per Part =

(Material Cost + Machine Time Cost + Labor Cost + Tooling Cost + Setup Allocation + QA Cost + Overhead)

+ Profit Margin

The final margin ensures operational sustainability and business profitability.

How to Reduce CNC Machining Costs

A machining supplier with experience in material behavior and fixture planning plays a significant role in cost efficiency. When the supplier understands which materials offer the best balance of performance and machinability, they can suggest alternatives that reduce tool wear and shorten cycle time without compromising structural or functional requirements. Well-designed fixturing also helps ensure the workpiece is held securely in an efficient orientation, reducing the number of setups required and minimizing labor and inspection overhead. This practical supplier insight leads to faster production, fewer delays, and more predictable, cost-effective outcomes across small and large batch sizes. Reducing CNC machining costs involves making strategic decisions throughout the design and manufacturing stages. Simplifying part geometry, avoiding unnecessary tight tolerances, and eliminating complex internal features can substantially decrease machining time and tool usage. Choosing machinable materials such as aluminum or engineering-grade polymers can also lower tool wear and reduce cycle duration, enabling faster production runs. Minimizing setups by designing parts that can be machined in fewer orientations reduces manual intervention and aligns the process for efficiency. Larger batch production further spreads initial setup and programming costs across multiple units, lowering the cost per part.

Modern production workflows also benefit greatly from digital simulation and CAM optimization. By validating toolpaths before CNC machine begins, shops can limit trial-and-error adjustments that waste machine time and material. Simulation ensures feeds, speeds, and cutting strategies are optimized for stability and efficiency. Together, these methods allow manufacturers to maintain high precision while controlling expense, resulting in a more streamlined and scalable machining process.

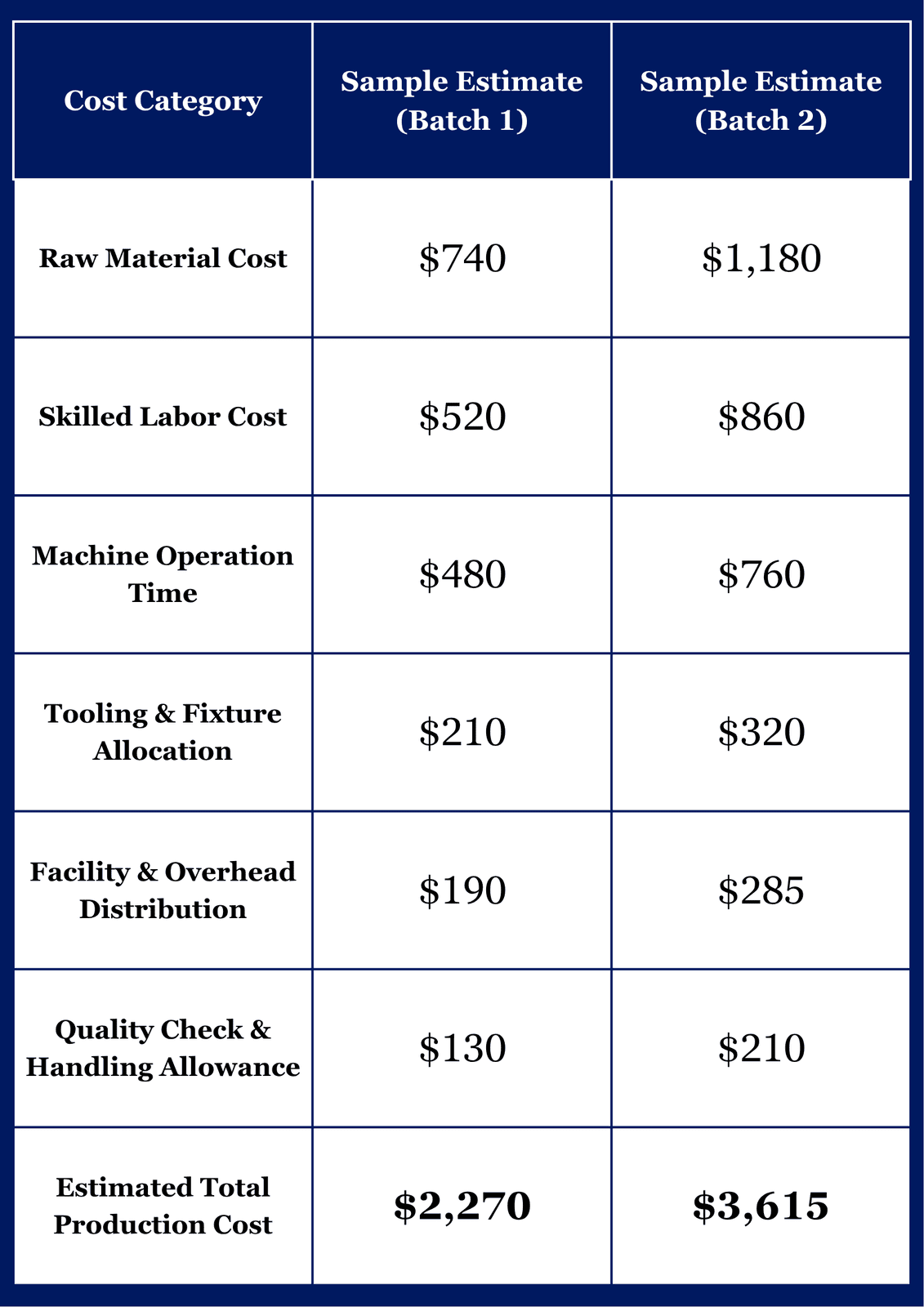

Final CNC Machining Cost Overview

The total cost of CNC machining is derived by evaluating several contributing elements that together define the financial scope of producing a part. Each component reflects a different stage of the manufacturing process, from acquiring raw material to maintaining shop operations. Material pricing depends on the grade, dimensions, and waste allowance. Labor reflects the programming, setup, monitoring, and finishing needed to achieve specification. Machine time represents the operational duration required to complete each machine cycle. Tooling and fixtures are necessary for precision and repeatability, especially when producing parts in higher volumes or with complex features. Overhead encompasses the essential operational support of the facility, including utilities, machine depreciation, software, and administrative processes. Additional expenses may include inspection of documentation, packaging, transportation, and allowances for unexpected adjustments or revisions. The following example is only intended to demonstrate how cost elements combine; actual machining costs will differ depending on geometry, tolerance, surface finish, and production scale.

Disclaimer:

The values shown above are illustrative examples only for understanding how cost components accumulate. Actual CNC machine pricing will vary depending on part size, tolerance levels, surface finish requirements, machining difficulty, production quantity, and the location and capabilities of the manufacturing provider.

Trustbridge Tip: Automate the "No" and accelerate the "Yes." Implement a smart, rapid triage system to instantly qualify high-potential RFQs, allowing your best estimators to focus their time and expertise only on high-fit, high-margin opportunities. Read the full blog

Conclusion:

Working with a CNC machining supplier that has strong expertise in material selection, fixture planning, and process optimization ensures that cost considerations are built into the production workflow from the beginning. Such partnerships help streamline machining operations, reduce unnecessary tool wear, avoid excessive setup time, and maintain dimensional accuracy across batches. When these elements are managed effectively, the result is not only controlled cost, but also consistent quality, dependable lead times, and smoother scaling from prototypes to volume production. Calculating CNC machining costs is not merely a pricing exercise; it is a strategic process that connects material choice, design efficiency, machine utilization, labor expertise, and overhead planning into a single cost structure. By understanding how each factor influences the final price, manufacturers and procurement teams can make informed decisions that support both precision and budget alignment. Cost-effective machining is achieved not by compromising quality, but by optimizing part geometry, selecting appropriate materials, minimizing setups, and leveraging digital simulation to streamline toolpaths and cycle times. As production scales, small decisions compound into meaningful savings, improving lead times and operational efficiency. With a clear, structured approach to cost calculation and optimization, CNC machining becomes not only a highly accurate manufacturing method but also a commercially sustainable one enabling organization to deliver reliable, repeatable, and high-value components at scale.

Ready to move your procurement from spreadsheets to strategy? AI is no longer optional — it’s the backbone of modern buying. Empower your procurement team with intelligent sourcing, real-time spend visibility, and smarter decision-making. Visit Trustbridge.pro to explore buyer resources, case studies, and solutions designed to help procurement professionals lead with confidence.

Frequently Asked Questions (FAQ)

1. What is the main factor that influences CNC machining cost?

The largest cost driver in CNC machining is typically machine time, which includes the cycle duration required to shape the part. Longer machining times result in higher hourly machine usage and increased tool wear. However, part complexity, material selection, and labor involvement also play significant roles in determining overall cost.

2. Why do complex part geometries increase machining cost?

Complex geometries often require slower cutting speeds, multiple setups, customized fixtures, and advanced programming. Features such as tight tolerances, deep cavities, undercuts, and multi-axis surfaces increase machining time and inspection requirements, which collectively raise production cost.

3. How does material selection affect machining pricing?

Materials vary in both raw cost and machinability. Softer materials like aluminum and plastics are easier to cut and extend tool life, resulting in lower machining cost. Harder materials such as stainless steel, titanium, and hardened alloys require high-performance tooling, slower feeds and speeds, and additional finishing steps, which increases cost.

4. Can CNC machining costs be reduced without sacrificing quality?

Yes. Cost reduction is often achieved through design optimization, selecting materials that balance performance and machinability, minimizing setups, producing parts in batches, and using digital simulation to refine toolpaths. These strategies improve efficiency while maintaining high precision standards.

5. How is CNC machining cost typically quoted by manufacturers?

Shops generally calculate cost by combining material expense, labor hours, machine time, tooling and fixture usage, quality assurance effort, and overhead allocation. These elements are summarized as a per-part price, which may decrease for larger order quantities due to setup cost distribution across more units.