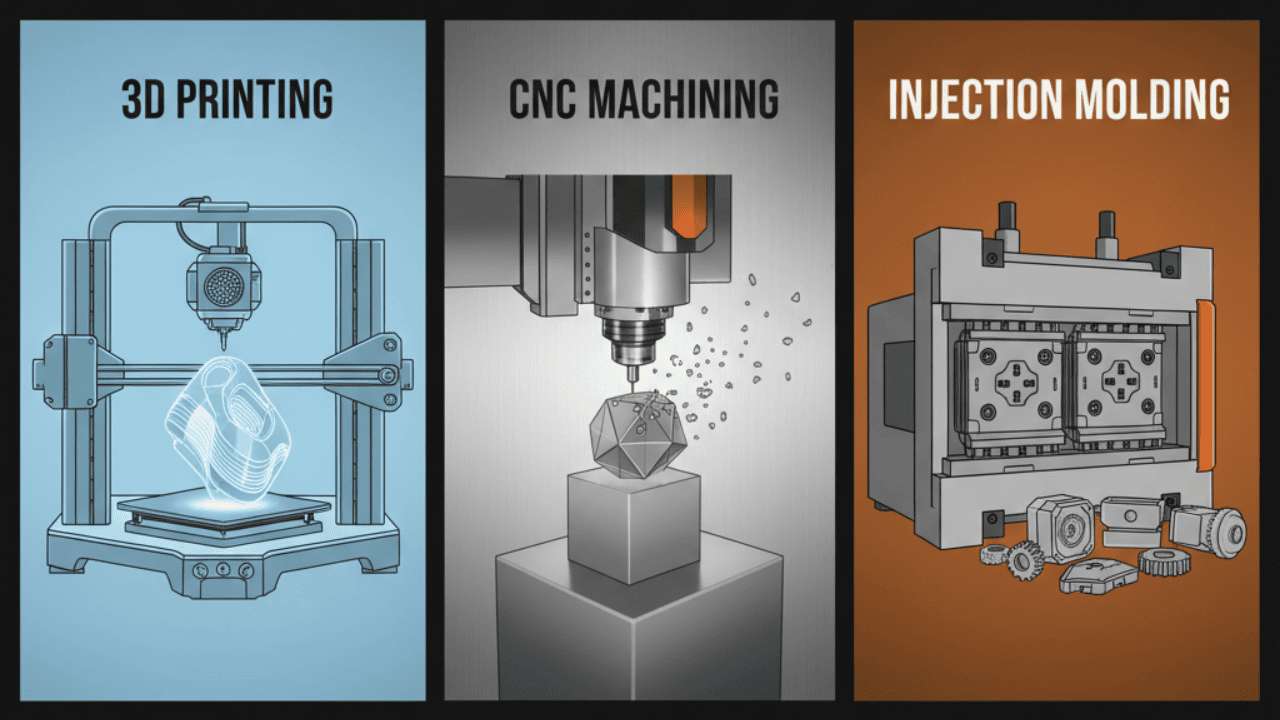

3D Printing vs. CNC vs. Injection Molding: What You Should Actually Use

In today’s competitive manufacturing landscape, choosing the right production process is more than a technical decision—it’s a strategic one. Whether you’re developing prototypes, producing small batches, or scaling into high-volume manufacturing, the choice between 3D printing, CNC machining, and injection molding directly influences your production costs, lead times, product quality, and overall supply chain efficiency.

At Trustbridge, we help businesses navigate these options with data-driven insights and design optimization strategies that align with their unique goals. Each technology brings distinct advantages: 3D printing supports rapid prototyping and design flexibility, CNC machining ensures high precision and material versatility, and injection molding delivers scalability and cost efficiency for mass production.

More importantly, the industry is moving toward integrated manufacturing workflows, where these processes don’t compete but complement one another. By combining the strengths of 3D printing, CNC, and injection molding within a smart manufacturing ecosystem, companies can streamline design, reduce costs, and accelerate time-to-market—unlocking a clear competitive edge.

Framing the Challenge: Matching Design with Process

Before diving into the technical details, it's essential to understand that the right manufacturing process is not a one-size-fits-all solution. It is a strategic choice dictated by the specific requirements of your part. This includes factors such as:

Part Complexity: Does your design feature intricate internal channels, organic shapes, or complex geometries that would be difficult or impossible to create with a traditional cutting tool?

Required Volume: Are you producing a handful of prototypes for a design review, a pilot run of a few hundred parts, or a massive production of millions?

Material and Performance: What kind of mechanical properties, surface finish and tolerances do the final part need to have?

Timeline: How quickly do you need to move from a digital model to a physical part?

These questions form the foundation of an effective design-for-manufacturability (DFM) analysis. As product designs grow more sophisticated—encompassing organic shapes, internal channels, and customized features—choosing the wrong method can result in escalating costs and extended lead times. The ideal match aligns the design complexity with process capabilities (additive flexibility, subtractive precision, molding scalability). Additional constraints like surface finish requirements and isotropic strength further influence the decision.

Trustbridge Tip: To get the best results with 3D printing, start with smart CAD design. By applying additive-specific strategies—like optimizing for lightweight structures, reducing material use, and accounting for anisotropy—you can cut costs and improve part performance. Explore Trustbridge’s guide on CAD innovations for additive manufacturing to design more effectively.

A Strategic Approach to Design and Sourcing

The core challenge of modern manufacturing is not just about understanding individual processes, but about knowing how to integrate them into a seamless, efficient workflow. This is where services like Trustbridge can provide significant value. They are designed to act as a bridge between a designer's vision and the complexities of global manufacturing.

Trustbridge's approach begins with a comprehensive Design-for-Manufacturability (DFM) analysis. Their in-house engineering team and network of collaborators work to analyze a design at its earliest stages, identifying potential issues with geometry, material selection, or feature design that could lead to costly problems down the line. This proactive analysis helps optimize a design for the most suitable manufacturing process, whether it's 3D printing for a rapid prototype, CNC machining for a functional part, or preparing a design for injection molding at scale. By providing this holistic solution, Trustbridge enables businesses to make data-driven decisions that align with their volume, budget, and timeline requirements, ultimately enhancing their speed-to-market and overall project success.

Strengths, Limitations, and Cost of Modern Manufacturing Processes

Strengths and Weaknesses of 3D Printing

3D printing, or additive manufacturing, is a process that builds objects layer by layer from a digital model. It has revolutionized the prototyping phase of product development and is increasingly being adopted for low-volume production and complex end-use parts.

Strengths:

Geometric Freedom: 3D printing's key advantage is its ability to create highly complex geometries, including intricate internal features, undercuts, and organic shapes that are impossible to produce with traditional methods. This allows for parts that are lighter, stronger, and more functionally integrated.

Speed and Cost for Prototyping: With minimal setup and no need for custom tooling, 3D printing offers an extremely fast and cost-effective solution for rapid prototyping and design iterations. You can go from a CAD file to a physical part in a matter of hours.

Weaknesses:

Anisotropy: Most 3D printed parts have inherent anisotropic properties, meaning their strength varies depending on the direction of the applied force relative to the build layers. This can be a critical limitation for parts requiring uniform mechanical strength.

Surface Finish and Tolerance: Although industrial 3D printers continue to improve, they generally don’t match the smooth surface finish or the tight tolerances of CNC machining or injection molding without additional post-processing. Many industrial 3D printing methods operate with broader tolerances compared to subtractive or molding techniques. Technologies like SLS (Selective Laser Sintering) and MJF (Multi Jet Fusion) deliver strong mechanical properties using materials such as nylon (PA11, PA12), and MJF is even touted for producing parts with strength approaching that of injection-molded equivalents.

Precision and Cost Profile of CNC Machining

CNC (Computer Numerical Control) machining is a subtractive process that uses automated cutting tools to remove material from a solid block or billet, resulting in a finished part.

Strengths:

High Precision and Material Variety: CNC machines are renowned for their ability to achieve extremely tight tolerances, often as precise as ±0.025 mm. This makes them ideal for parts with critical dimensional requirements. They can also work with a vast range of materials, including metals, plastics, wood, and composites, offering superior material properties.

Excellent Surface Finish: The subtractive nature of CNC machining naturally produces parts with a very smooth and consistent surface finish, often requiring little to no post-processing. Dimensional accuracy often lies within ±0.025 mm to ±0.125 mm for high-end CNC operations, significantly tighter than most 3D printing methods.

Weaknesses:

Cost for Complex Geometry: The cost of CNC machining is highly dependent on part complexity. Features that require multiple setups, complex tool paths, or undercuts can drive up costs and lead times significantly. Material waste is also a factor, as a large amount of material may be removed to create the final shape.

Economical for Low Volumes: While efficient for medium to high volumes, the initial setup and programming costs make CNC machining less economical for single prototypes or very small production runs compared to 3D printing. According to industry data, the cost per part for CNC machining can be significantly lower than 3D printing once production volume surpasses 100 units, making it a viable option for small-batch production and functional prototypes. The trend of hybrid CNC machines, which combine subtractive and additive methods, is emerging to address some of these limitations, offering a glimpse into the future of integrated manufacturing.

Scalability and Unit Cost of Injection Molding

Injection molding is a manufacturing process that injects molten material into a custom-designed mold. After the material cools and solidifies, the part is ejected.

Strengths:

Unmatched Scalability and Low Unit Cost: This is the undisputed champion of mass production. Once the initial tooling is created, injection molding can produce millions of parts with a very low unit cost and exceptional repeatability.

Material Variety and Consistency: The process works with a wide range of thermoplastic and thermosetting materials, and the parts produced have consistent, isotropic mechanical properties, making them strong and reliable.

Weaknesses:

High Up-Front Tooling Expense: The primary barrier to entry is the significant initial investment in tooling, which can range from thousands to hundreds of thousands of dollars.

Long Lead Times: Designing and manufacturing a high-quality mold can take weeks or even months, making it unsuitable for rapid prototyping or design iterations.

Trustbridge Tip: When designing for CNC machining, avoid sharp internal corners, they're hard on tools and expensive to produce. Instead, use fillets to make your parts easier and more cost-effective to machine. For more practical design tips, check out the full Trustbridge blog: What Are Some Tips for Designing for CNC Machining.

Choosing the Right Process

Volume Thresholds and Break-Even Tooling Points

Deciding between these three technologies often comes down to one critical factor: volume.

3D Printing: The most cost-effective solution for a single prototype or a batch of less than 10-20 parts. Its low-cost setup and quick turnaround time make it the clear winner for early-stage development and conceptual modeling.

CNC Machining: The economic sweet spot for medium-to-low volume production, typically ranging from 10 to a few thousand parts. At this scale, the superior precision and material options of CNC outweigh the higher cost per part of 3D printing, while avoiding the prohibitive tooling expense of injection molding.

Injection Molding: The only viable option for high-volume production, starting from thousands to millions of parts. While the up-front cost is high, the negligible cost per part quickly offsets the initial investment. A critical data point to consider is the "break-even point"—the number of parts at which the total cost of injection molding (tooling + unit cost) becomes lower than the total cost of CNC machining or 3D printing. For many projects, this point is often reached around 5,000 to 10,000 units, but this can vary widely based on part complexity and material choice. This economic model is paramount for businesses planning to scale their product, as it dictates the long-term profitability and sustainability of a manufacturing run.

Surface Finish and Tolerance Considerations

The required surface finish and dimensional tolerance of your part are crucial technical considerations that can immediately narrow down your options.

CNC Machining: Delivers the highest level of dimensional accuracy and a smooth, consistent surface finish right off the machine. This is non-negotiable for parts that require tight fits, interlocking components, or critical mechanical performance. Tolerances as low as ±0.025 mm are standard.

Injection Molding: Provides a high-quality surface finish and excellent part-to-part consistency, though dimensional tolerances may not be as tight as CNC machining for every feature. The finish is directly determined by the mold cavity's surface.

3D Printing: Has a characteristic layered texture that may require extensive post-processing (sanding, polishing, coating) to achieve a smooth finish. Tolerances are generally looser, with industrial-grade printers reaching ±0.1 mm on average. Industry sources consistently emphasize that surface finish is a key differentiator for end-use parts, especially consumer-facing goods. Smooth finishes enhance not just functionality but also aesthetic appeal, durability, coating adhesion, and even wear resistance—factors that keep CNC machining and injection molding highly relevant in modern manufacturing.

Lead Time and Speed-to-Market Alignment

The speed with which you can get a finished part in your hands can be the difference between leading the market and falling behind.

3D Printing: Unrivaled for speed in the early stages. The ability to produce a prototype in a day or two allows for rapid iteration and validation of design concepts, accelerating the development cycle.

CNC Machining: Offers a quick turnaround for functional prototypes and low-volume batches, often with lead times of a few days to a couple of weeks, depending on part complexity and material availability.

Injection Molding: The slowest process to get started due to the long lead time for mold fabrication. However, once the mold is ready, the cycle time for producing each part is incredibly fast, often in a matter of seconds. It’s also worth noting that leveraging 3D printing in the prototyping phase can reduce product development lead times by up to 75% compared to traditional methods . This speed advantage in early design validation plays a critical role when weighing volume thresholds and break-even economics across 3D printing, CNC machining, and injection molding. Quickly reduces risk and ensures that the final mass-produced item is robust and well-validated.

Break-even Economics at a Glance

These volume thresholds are industry benchmarks rather than fixed rules. The actual break-even point can vary widely depending on factors such as part complexity, material choice, and supplier pricing. Still, the following ranges provide a practical framework for comparison.

Comparison Table

Process | Ideal Volume Range | Key Advantage |

3D Printing | <10–20 units | Fast, flexible, low setup cost |

CNC Machining | 20 – ~5,000 units | High precision, wide material choice |

Injection Molding | 5,000+ units | Lowest per-unit cost at scale, unmatched repeatability |

Conclusion: A Strategic Blended Approach

Ready to move your procurement from spreadsheets to strategy? AI is no longer optional — it’s the backbone of modern buying. Empower your procurement team with intelligent sourcing, real-time spend visibility, and smarter decision-making. Visit Trustbridge.pro to explore buyer resources, case studies, and solutions designed to help procurement professionals lead with confidence.