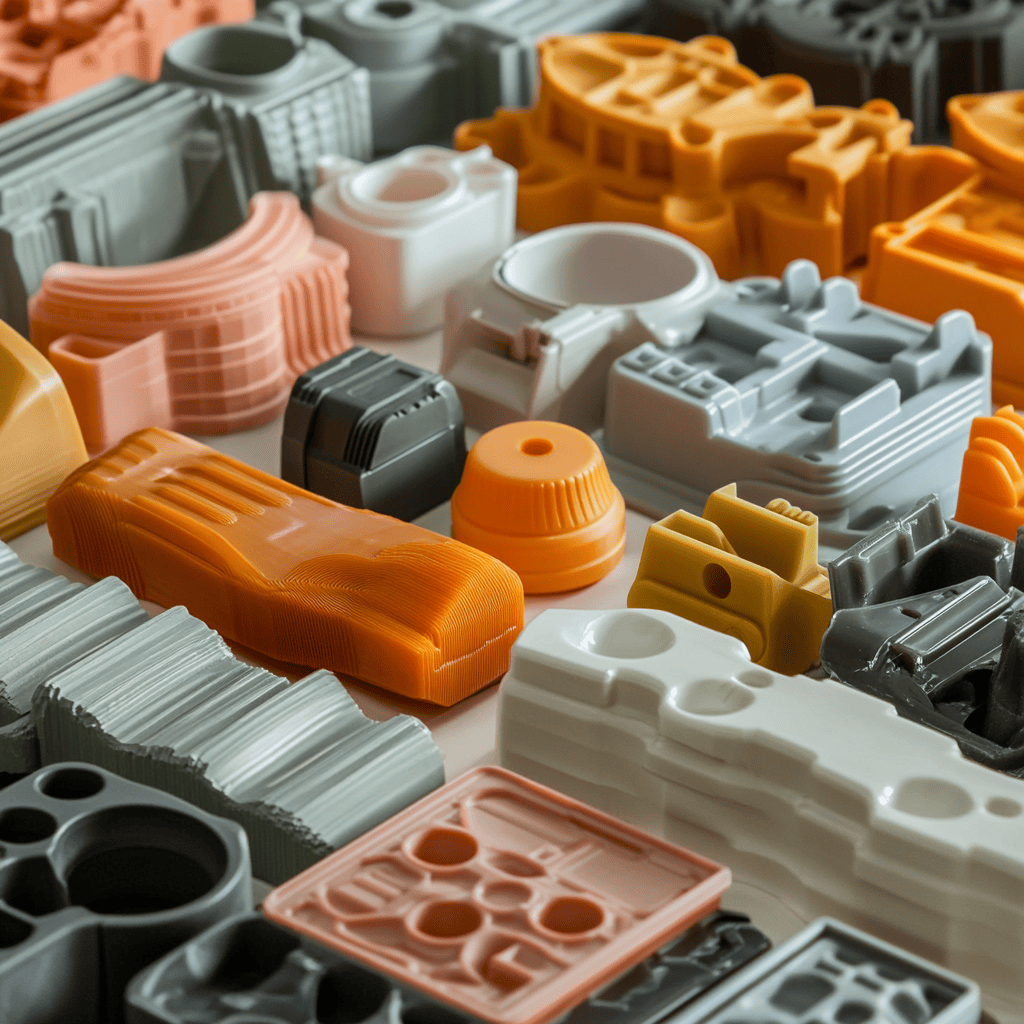

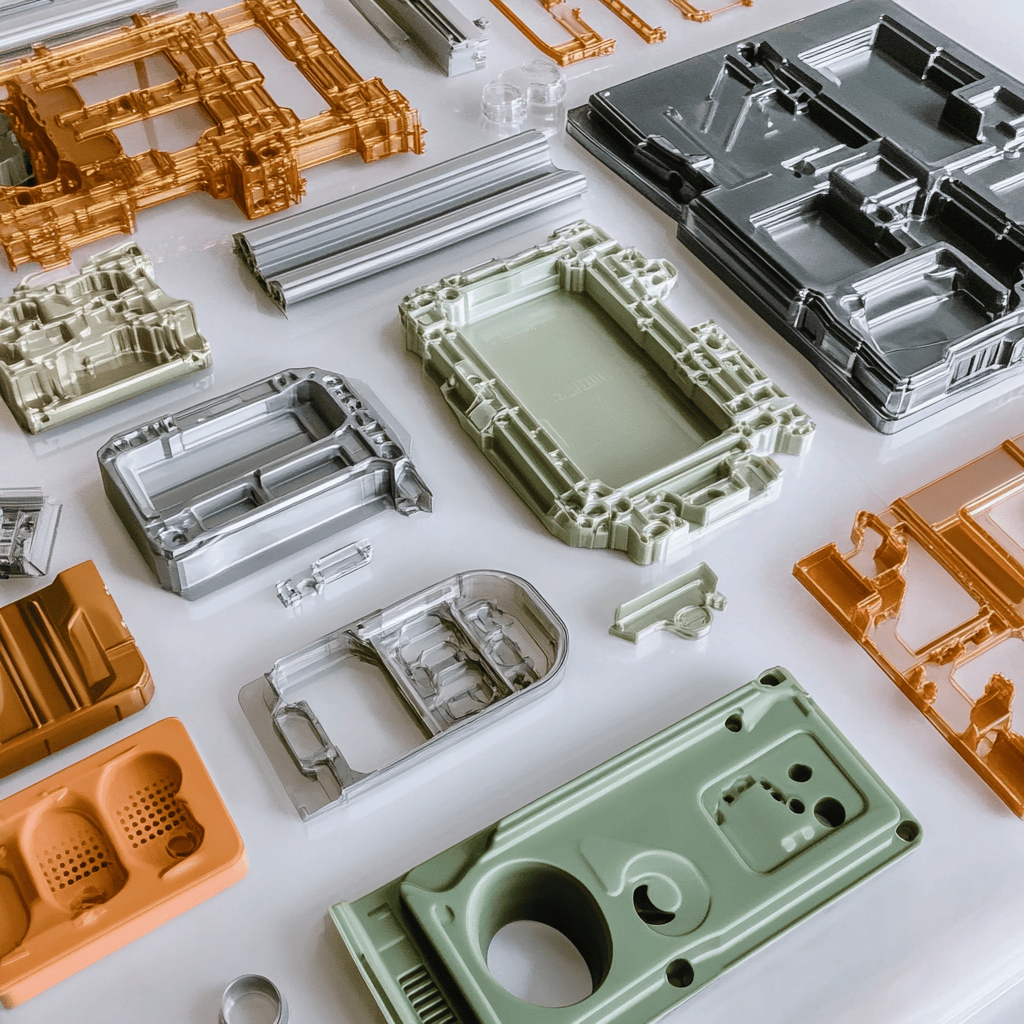

Trustbridge offers end-to-end plastic injection molding services through a global network of certified molders. From rapid prototyping to high-volume production, we connect your project to the best-fit partner based on mold complexity, part geometry, material requirements, and certifications.

Whether you're launching a new consumer product or producing mission-critical medical or automotive components, Trustbridge combines intelligent supplier matching with in-house engineering support to ensure quality, consistency, and speed — from first shot to full production.

Frequently Asked Questions

Ready to Start Your Plastic Injection Molding Project?

Explore Related Services

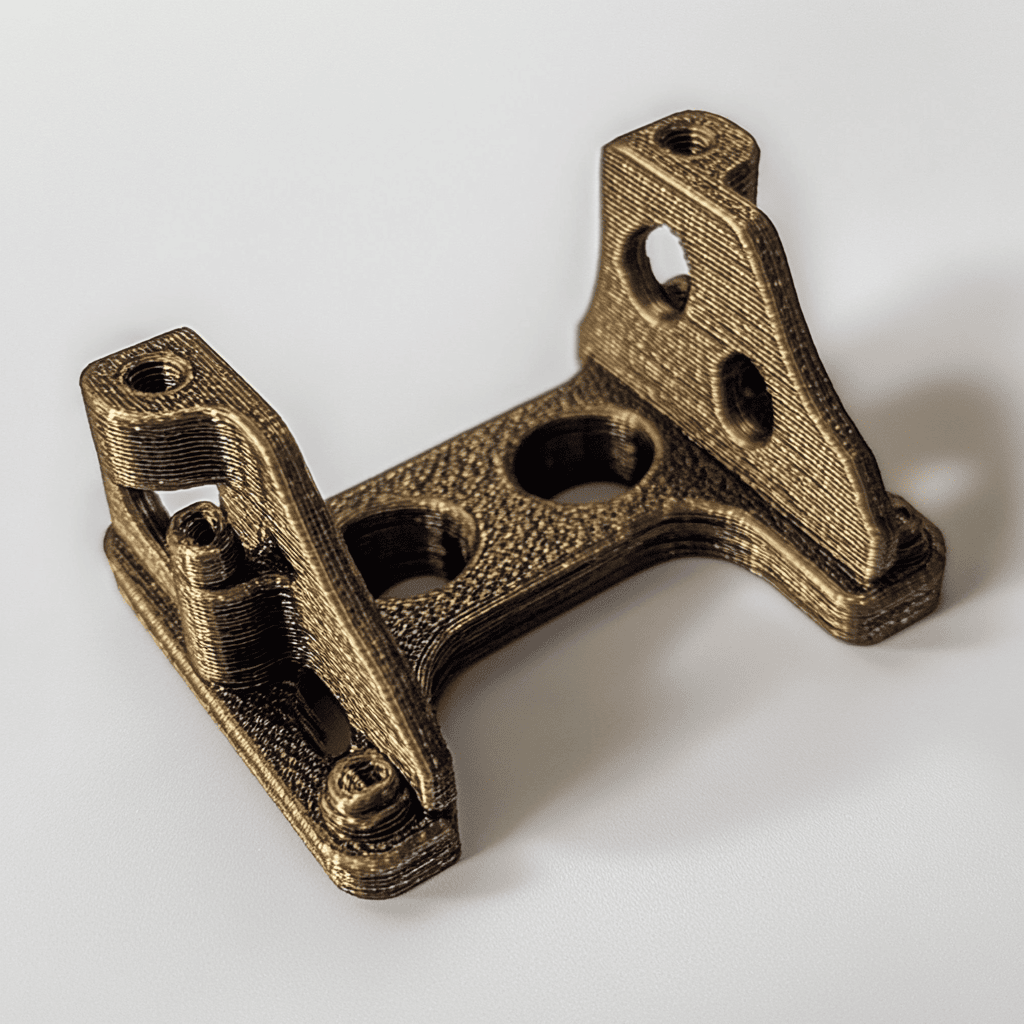

3D Printing

Rapid, cost-effective prototyping and low-volume production with complex geometries and minimal tooling.

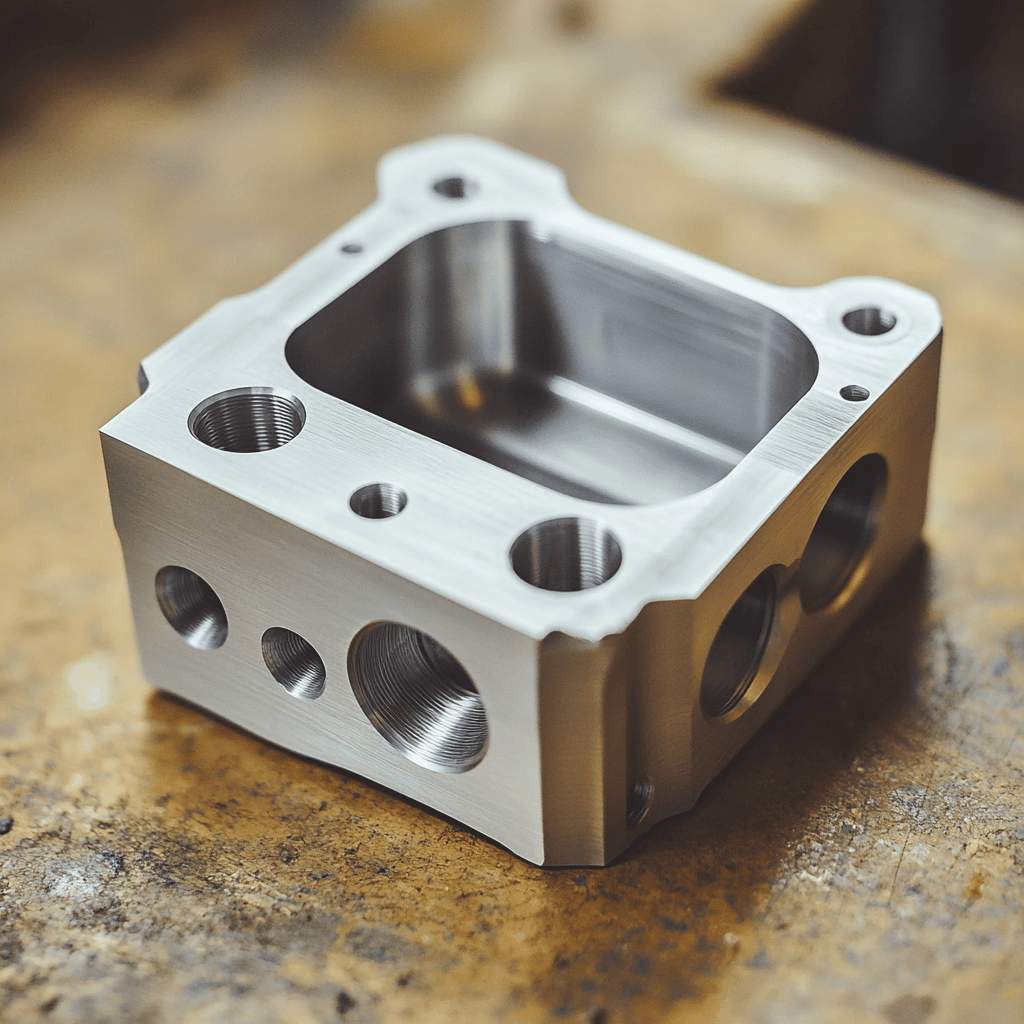

CNC Machining

Precision-cut metal and plastic parts with tight tolerances and excellent surface finish — ideal for prototyping and production.

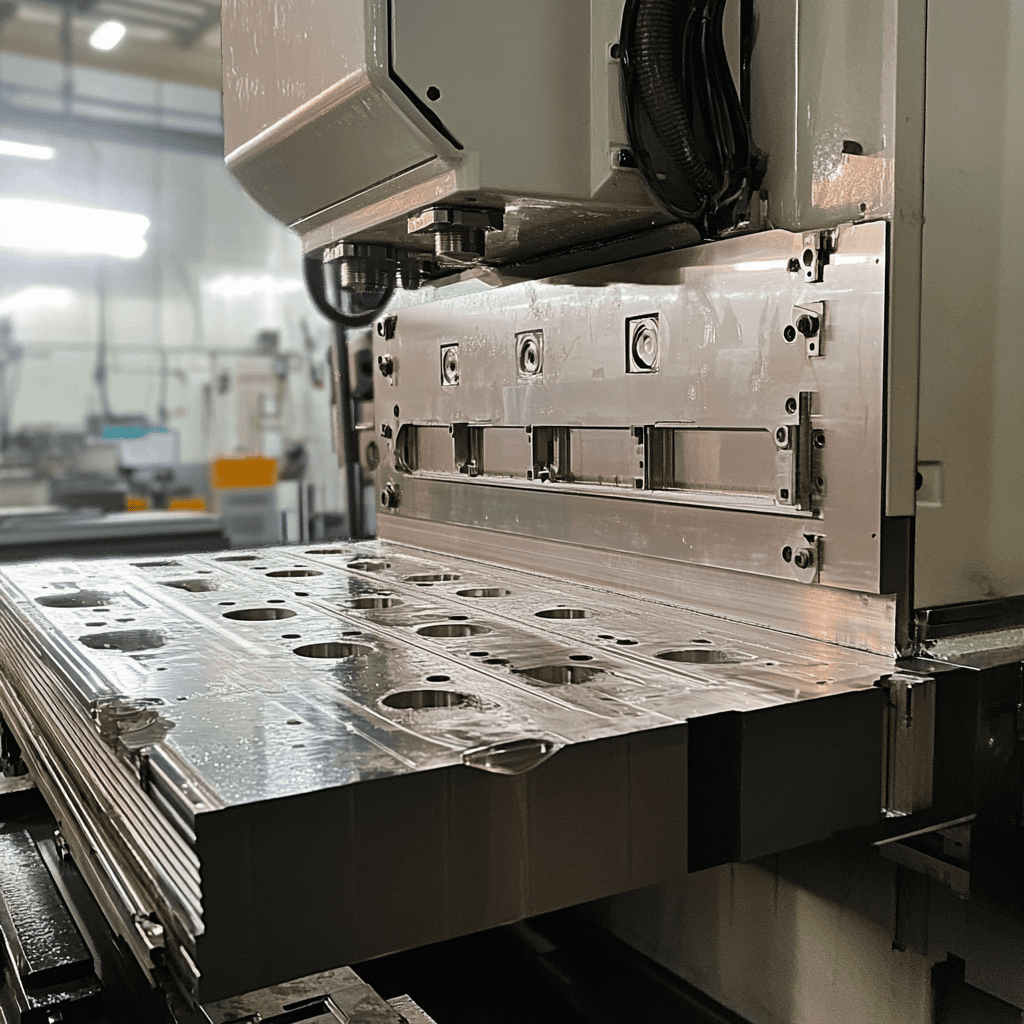

Sheet Metal Fabrication

Cut, bend, and assemble custom enclosures, brackets, and panels — scalable from prototypes to full production runs.