Trustbridge offers full-spectrum metal casting services through a global network of certified foundries and casting specialists. Whether you need functional prototypes, short-run pre-production parts, or full-scale metal component manufacturing, our platform connects your requirements to suppliers with the right alloy, casting method, and finishing capabilities.

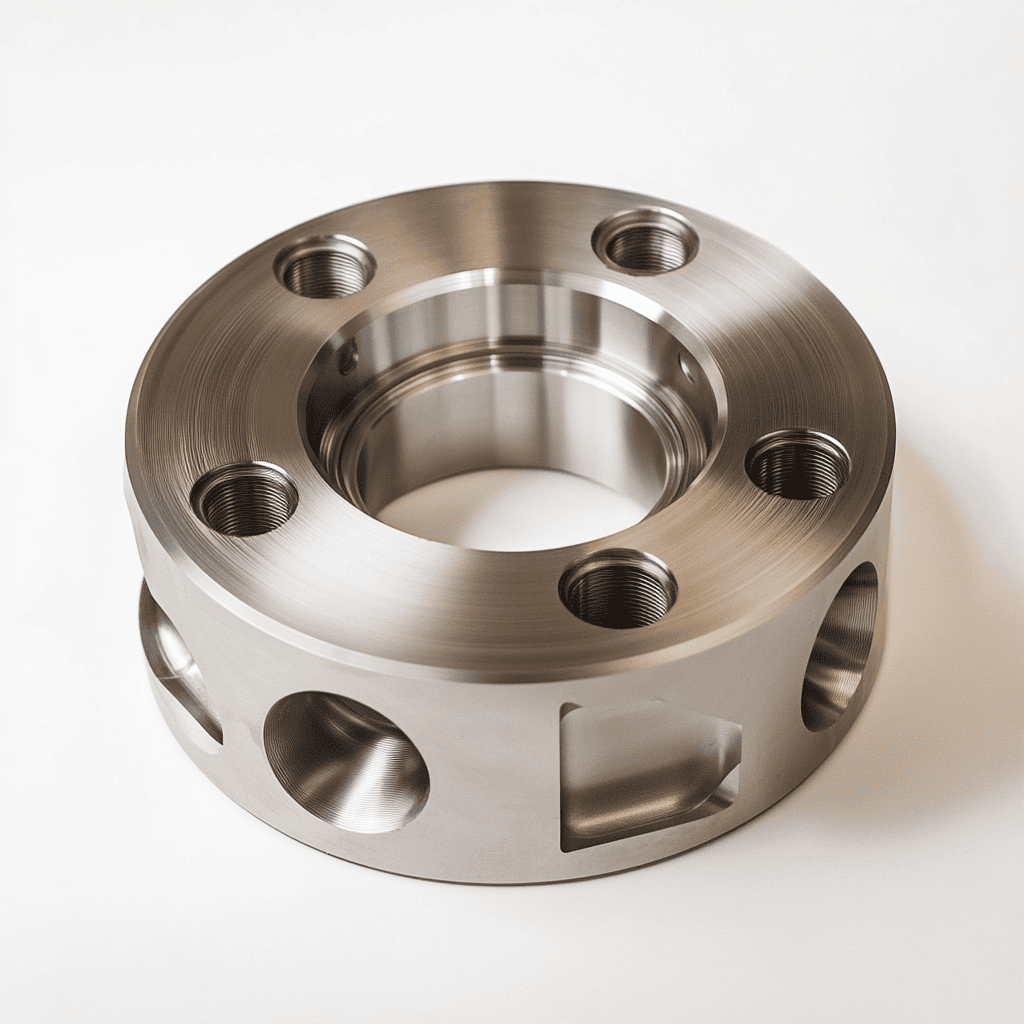

From investment casting to sand and die casting, we support diverse industries with high-strength, complex geometries — all backed by engineering support, global sourcing flexibility, and a single point of contact for quality assurance.

Frequently Asked Questions

What’s the difference between investment, sand, and die casting?

- Investment Casting: Best for detailed parts, lower volumes

- Sand Casting: Lower tooling cost, flexible geometry

- Die Casting: Best for high-volume runs, especially aluminum and zinc

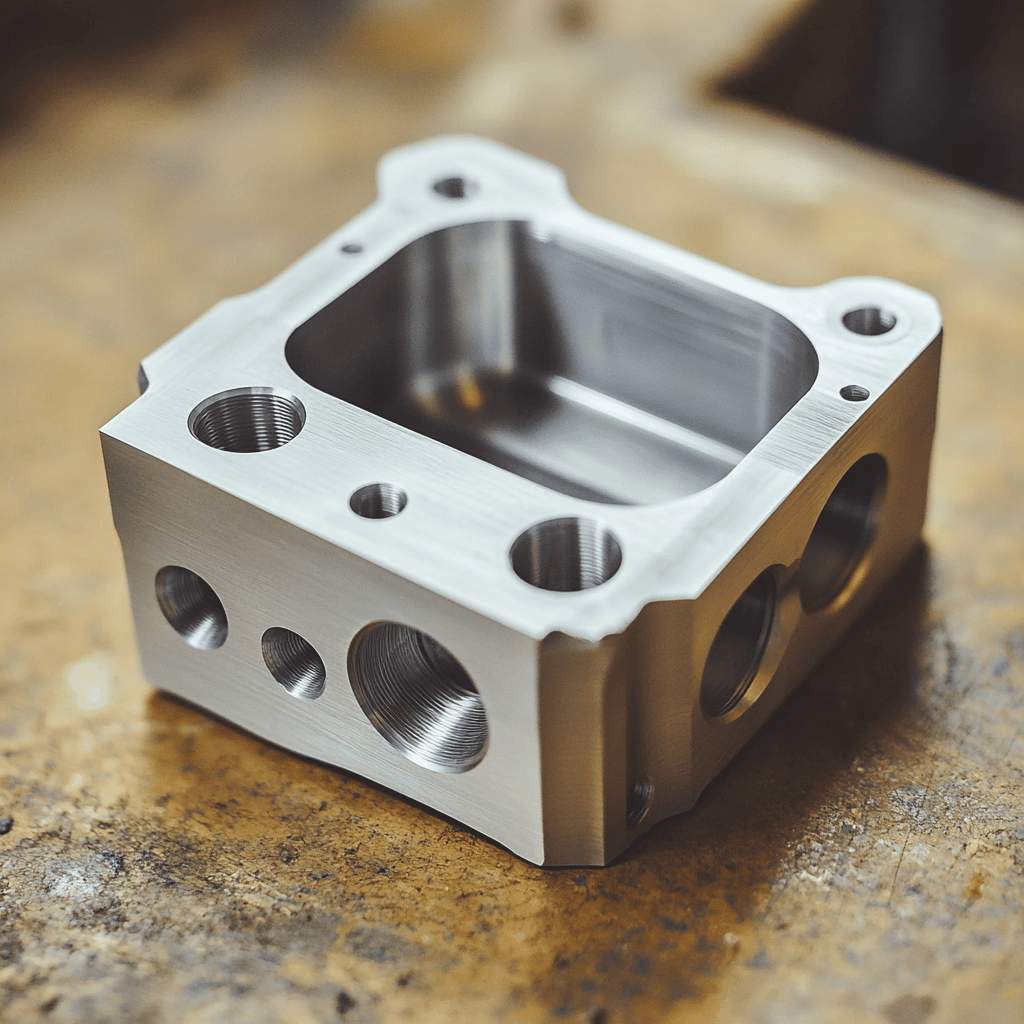

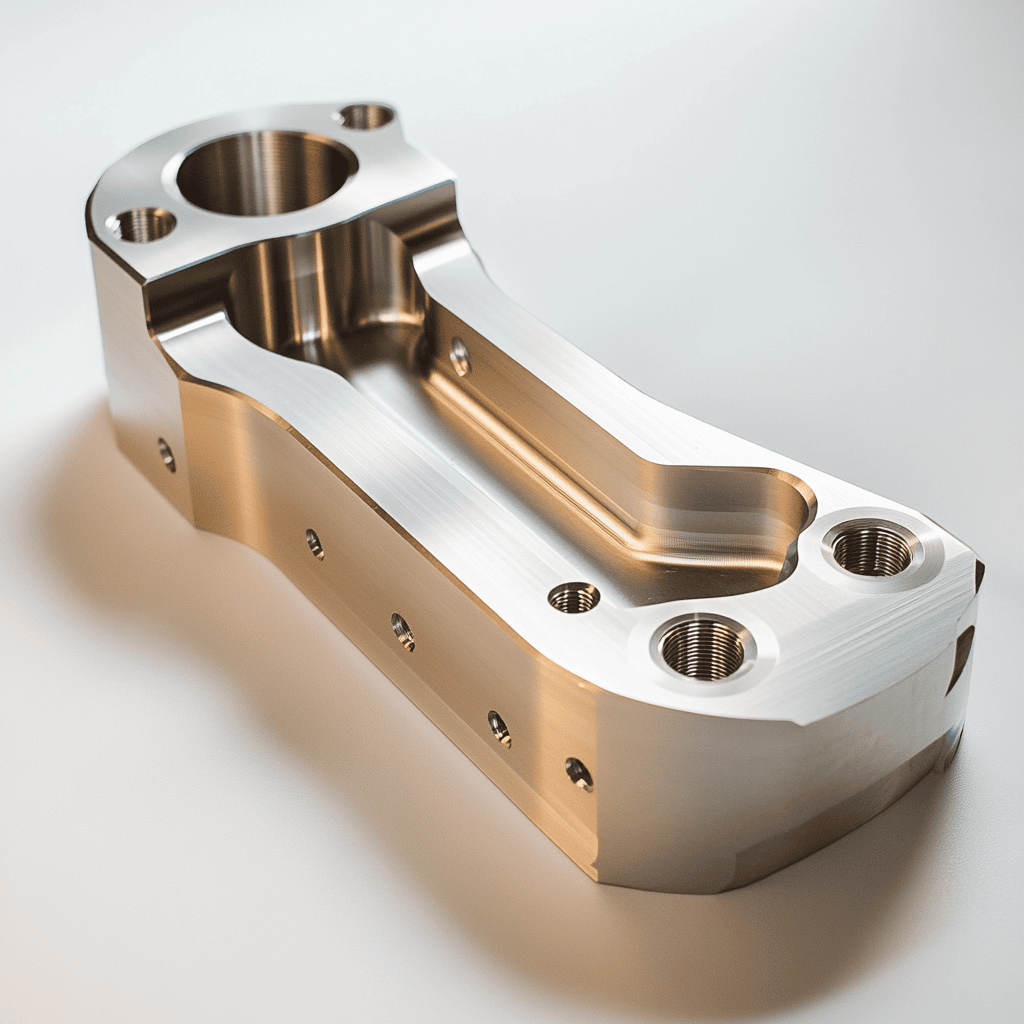

What post-processing services do you offer?

We offer machining, heat treatment, polishing, anodizing, painting, powder coating, and NDT testing.

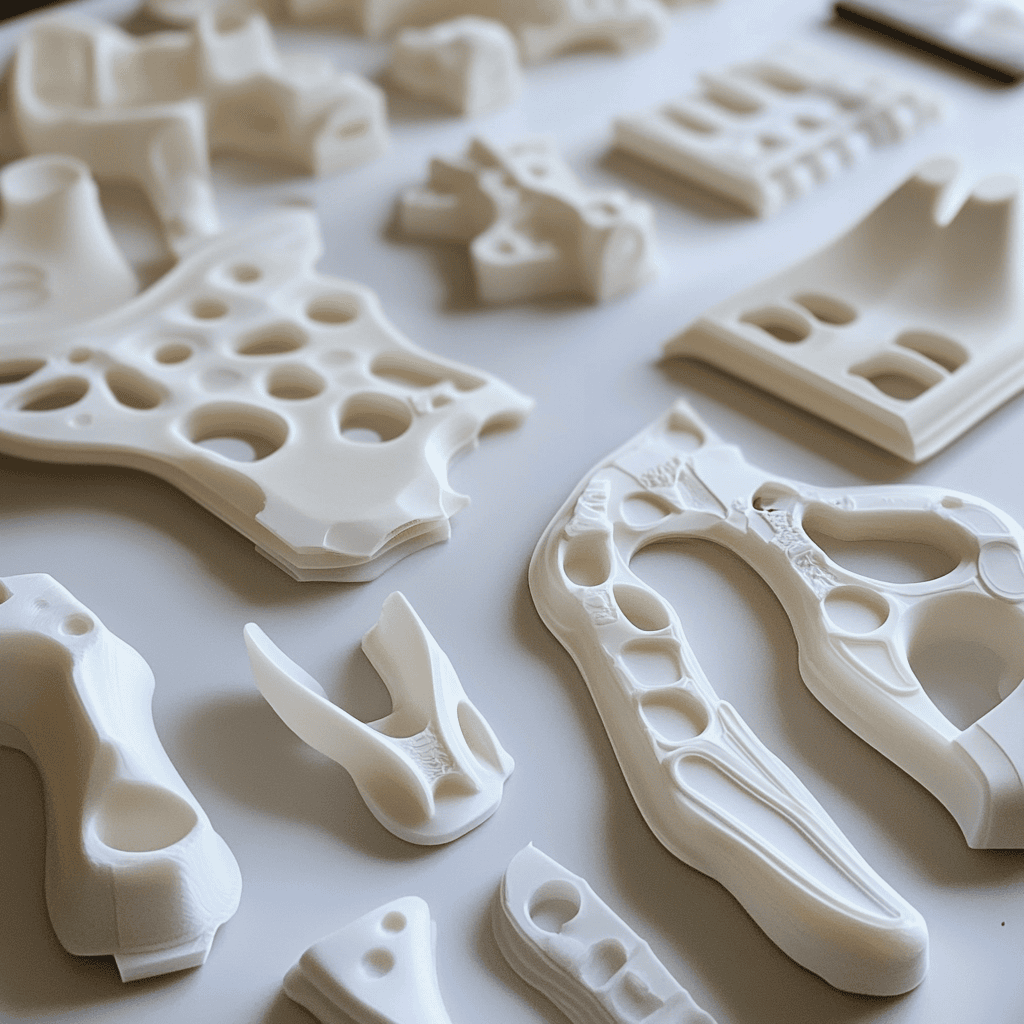

Can I use 3D-printed patterns for short-run casting?

Yes — many of our partners support rapid pattern generation using SLA, FDM, or binder jet printing.

Do you support cast + machined parts in one job?

Yes — we can bundle casting and post-processing into a single quote and project workflow.

Can I get help choosing the right casting process or alloy?

Absolutely. Our engineering team provides hands-on guidance at every stage.

Ready to Start Your Metal Casting Project?

Let our team help you scope the right process, material, and supplier for your next casting project.