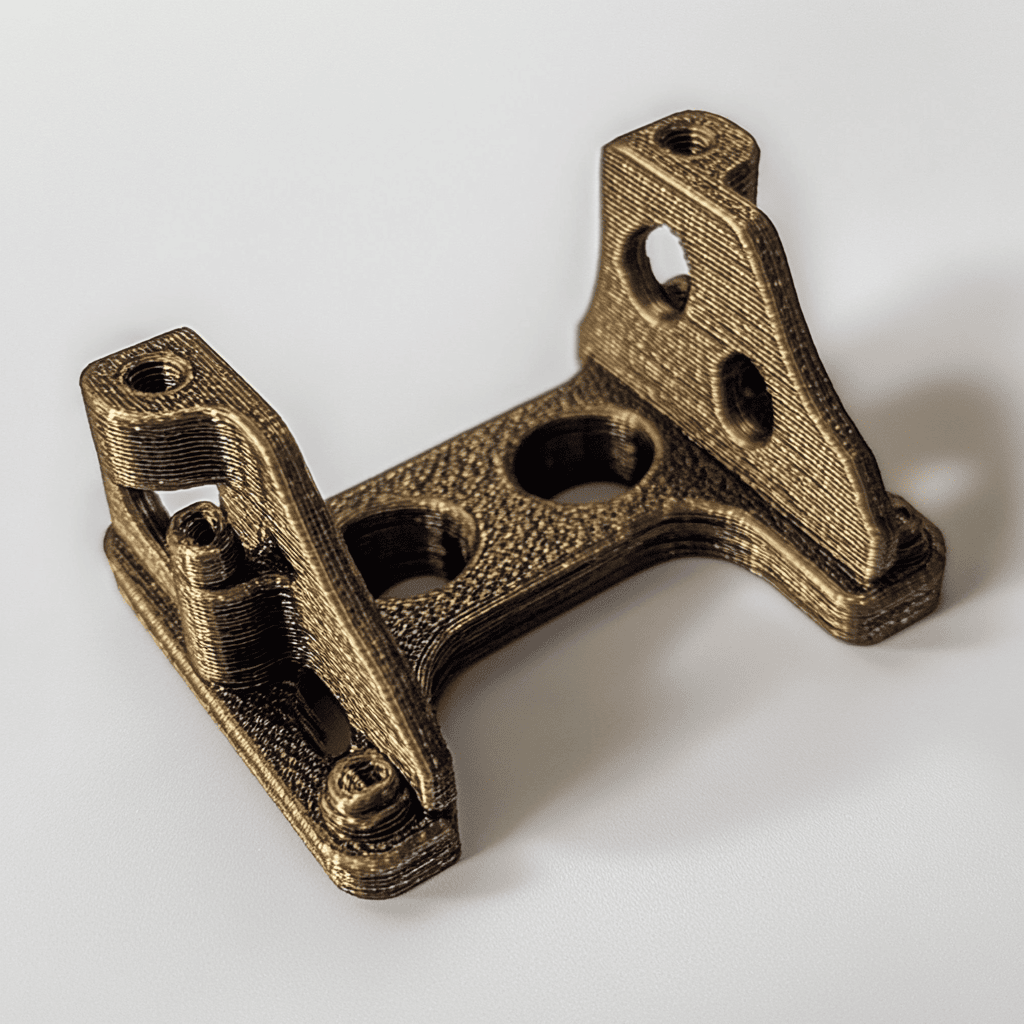

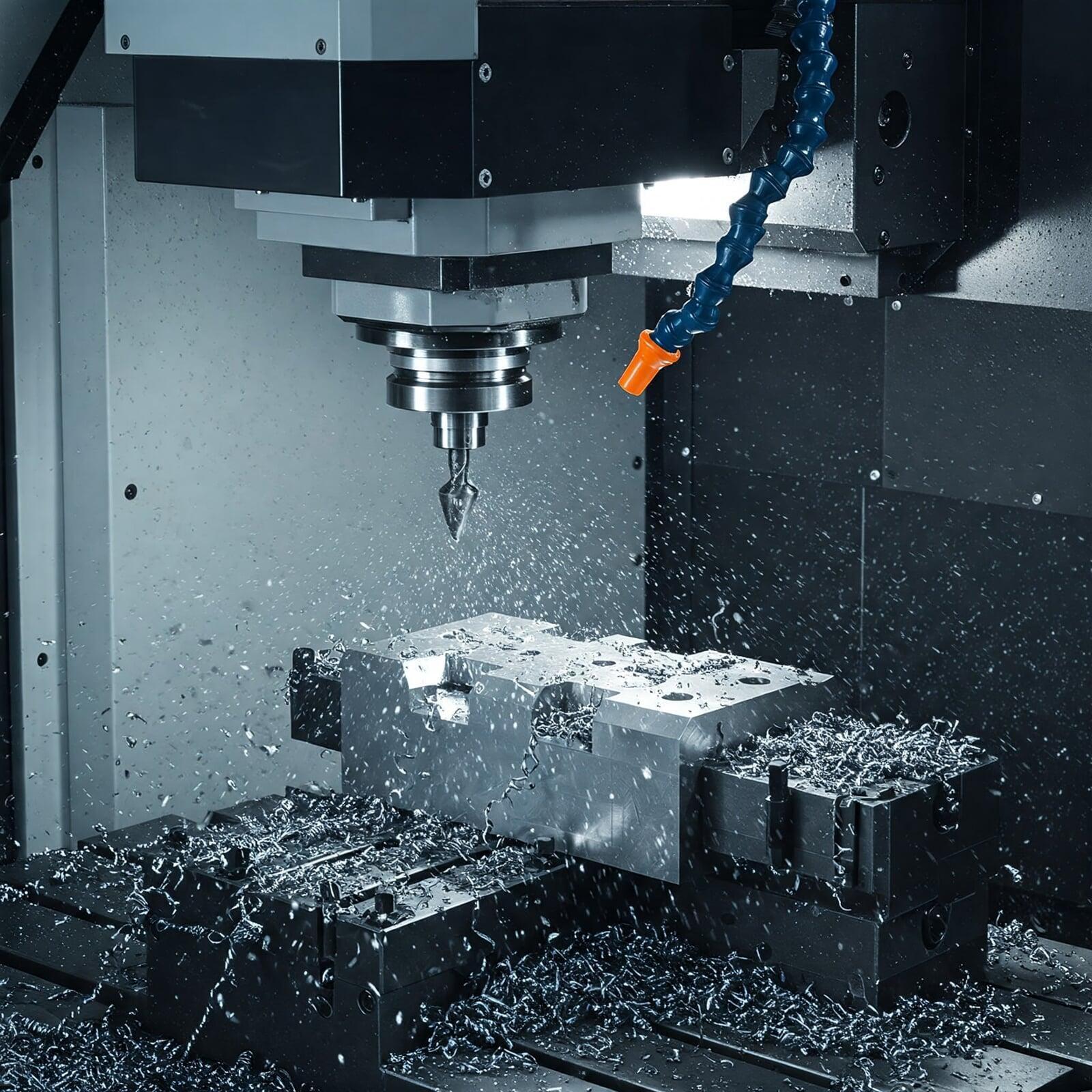

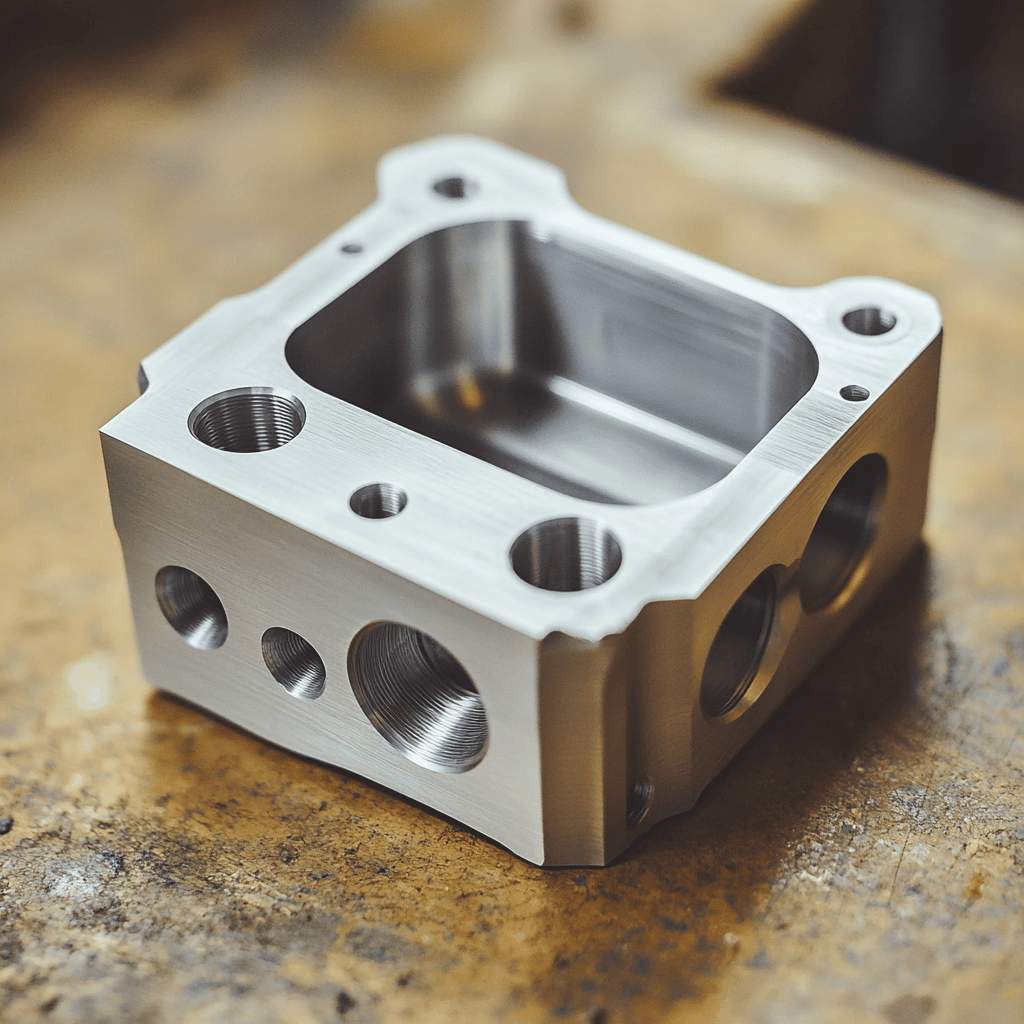

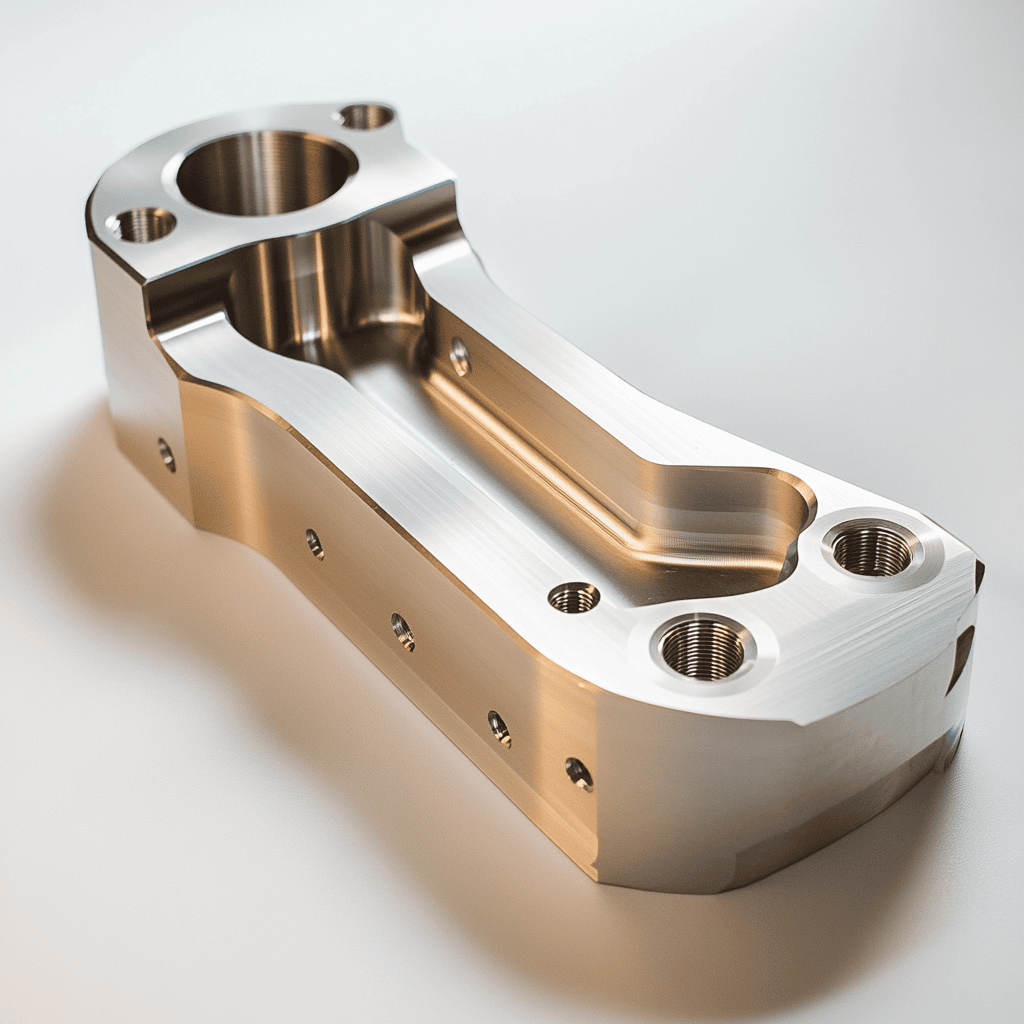

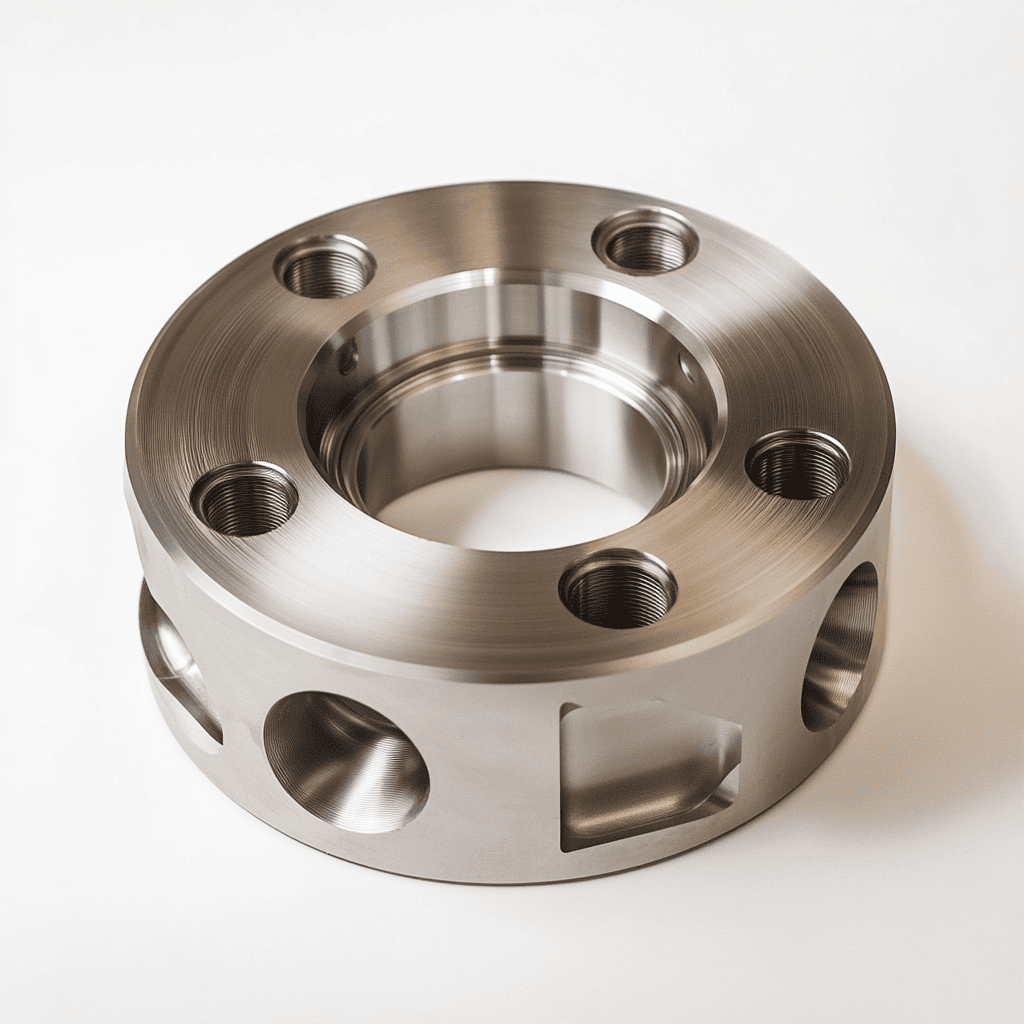

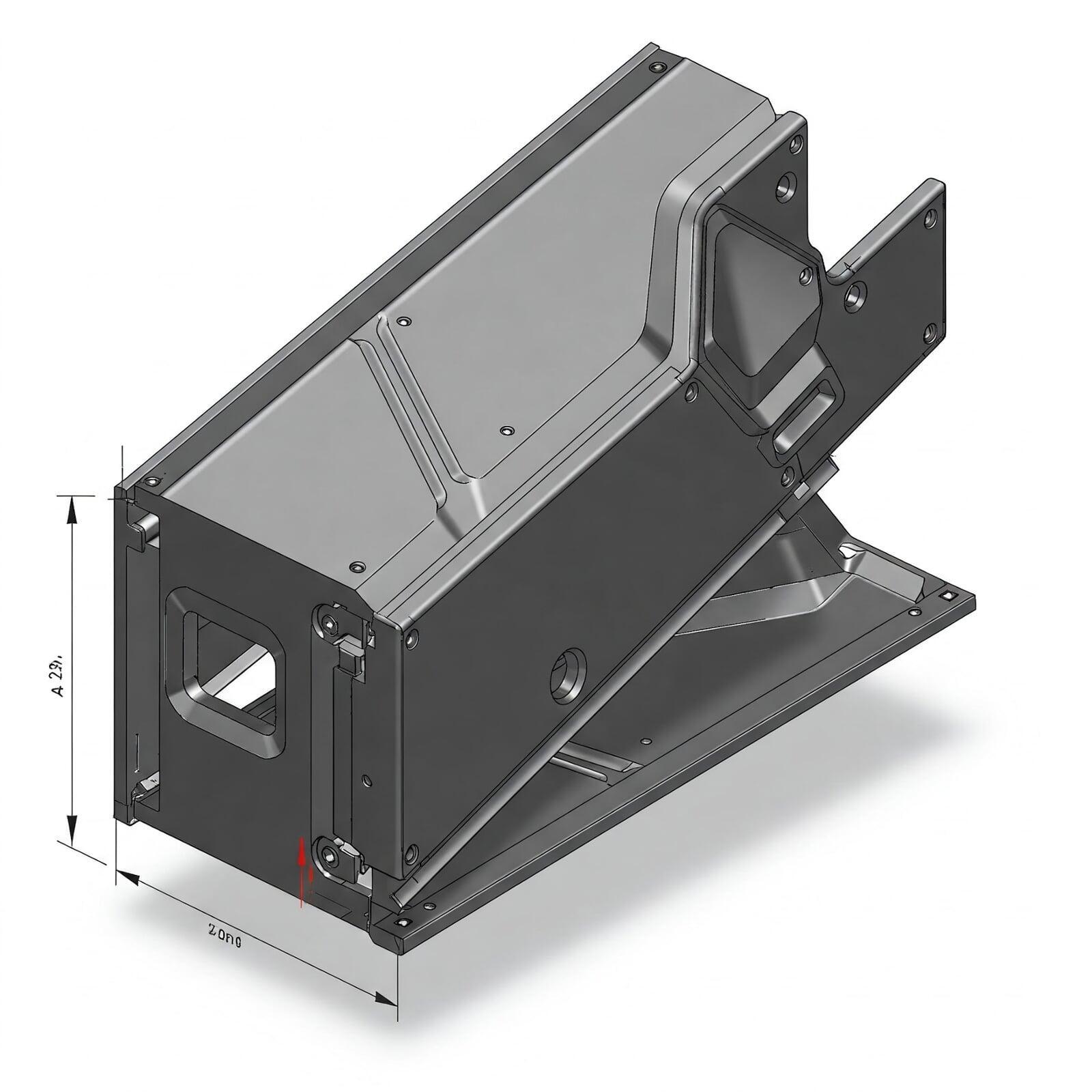

Trustbridge delivers precision CNC machining services through our global network of certified and highly vetted manufacturing partners. Whether you need rapid prototypes, small-batch production, or full-scale part runs, we match your exact technical requirements to the right supplier — based on capabilities, certifications, location, and lead time.

From simple brackets to complex 5-axis parts, our platform gives you access to the full range of CNC milling and turning technologies, coupled with in-house engineering support to ensure your parts meet spec the first time — and every time. Trustbridge is your smarter sourcing solution for tight tolerances, high-performance materials, and scalable production.

Frequently Asked Questions

What files do you accept?

We accept STEP, IGES, SLDPRT, STL, and DXF files, along with 2D drawings (PDF) for tolerances and finishes.

What’s your standard turnaround time?

Typically 3–5 business days for smaller orders, with expedited options available in major metro areas.

Can I request a custom surface finish?

Yes — we support bead blasting, anodizing, powder coating, polishing, and more.

Are my designs secure?

Yes — Work is done under NDA by default. All files shared via Trustbridge are encrypted. While all suppliers have been vetted for reasonable file security protocols, engage with them to confirm.

Explore Related Services

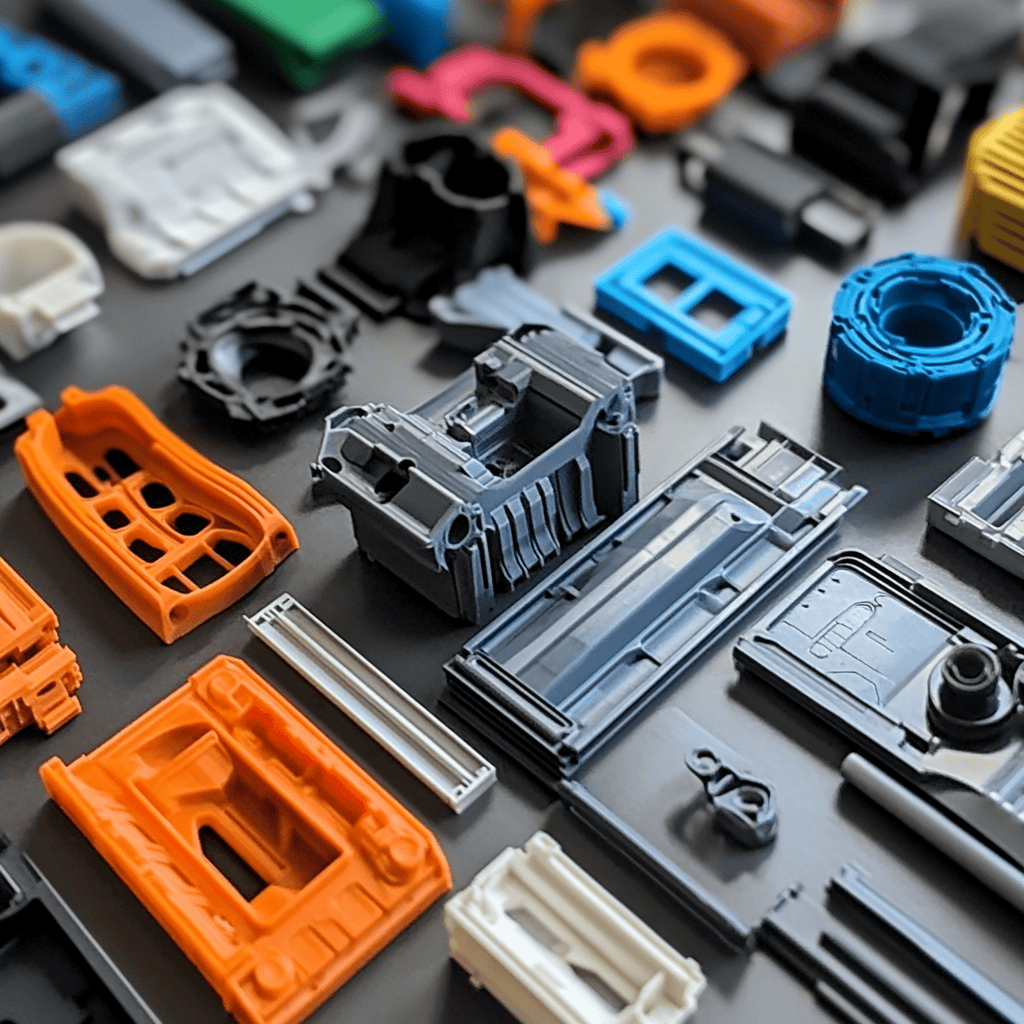

3D Printing

Rapid, cost-effective prototyping and low-volume production with complex geometries and minimal tooling.

Sheet Metal Fabrication

Cut, bend, and assemble custom enclosures, brackets, and panels — scalable from prototypes to full production runs.

Injection Molding

High-volume plastic part production with consistent quality, fast cycle times, and low per-unit cost once tooled.